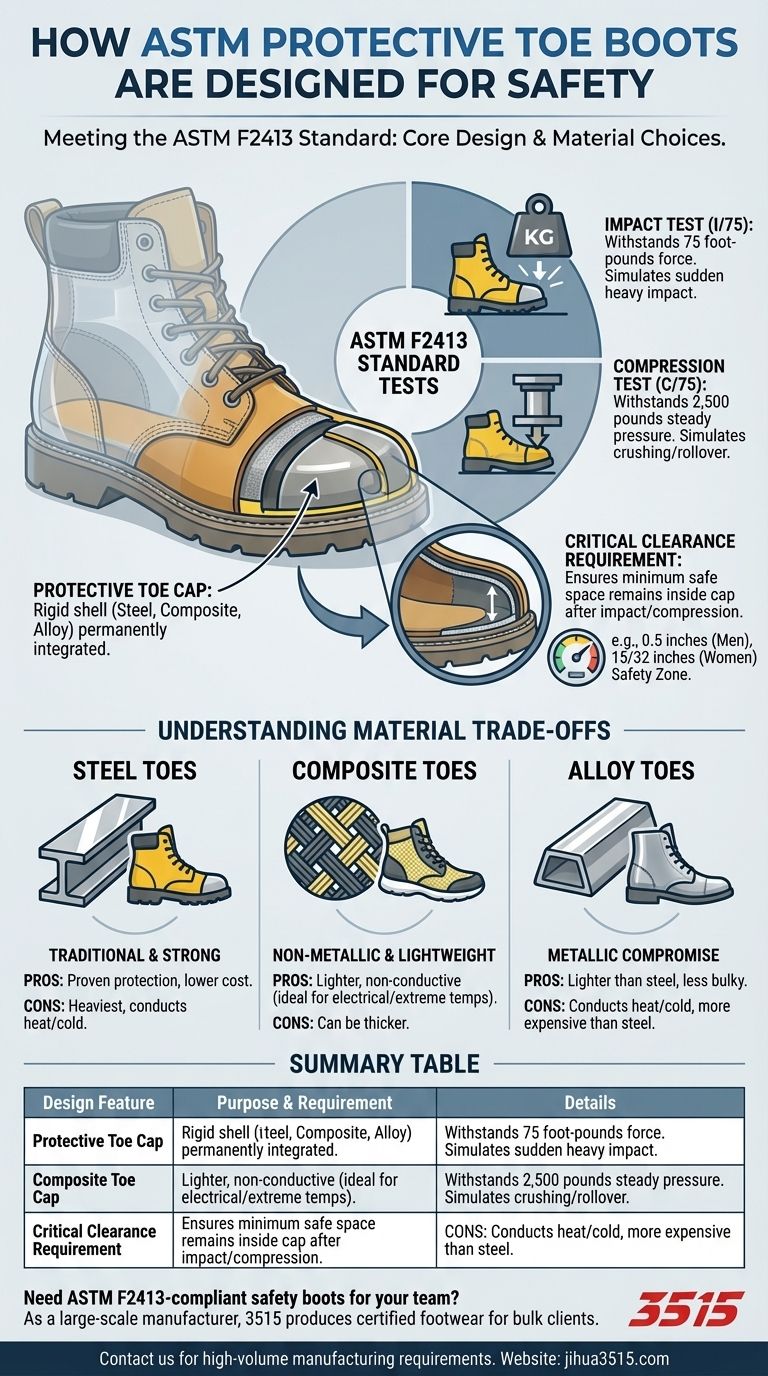

Boots designed to meet ASTM protective toe standards are built around a single critical component: a reinforced toe cap. This cap, typically made of steel, composite materials, or alloy, is integrated into the front of the boot to withstand specific, standardized forces of impact and compression, ensuring a minimum space is maintained to protect the wearer's toes from injury.

The core design principle isn't just about using a strong material in the toe. It's about engineering a complete system that is proven to withstand 75 foot-pounds of impact and 2,500 pounds of compression while preserving a critical safety clearance inside the boot.

The Core Design: A Protective System

At its heart, a protective toe boot is a standard work boot with a crucial reinforcement built directly into its structure. This design is not arbitrary; it's precisely engineered to pass rigorous tests.

The Protective Toe Cap

The toe cap is a rigid, anatomically shaped shell. It is permanently inserted into the toe box of the boot, sitting between the outer leather or fabric and the inner lining.

This integration ensures the cap cannot shift or be removed, providing a constant shield for the toes.

The ASTM F2413 Standard

The design is entirely driven by the performance requirements of the ASTM F2413 standard. This standard specifies two key tests that a protective toe must pass.

The Impact (I/75) Test

This test measures the boot's ability to protect the toes from a sudden, heavy impact. A weight is dropped onto the toe cap to create 75 foot-pounds of force.

To pass, the boot must maintain a specific minimum interior clearance after the impact. This simulates a heavy object falling directly onto the foot.

The Compression (C/75) Test

This test measures protection from crushing or rollover events. The boot's toe is subjected to 2,500 pounds of steady pressure.

Similar to the impact test, the critical factor is the amount of clearance remaining inside the cap after the force is applied.

The Critical Clearance Requirement

The ultimate goal of the design is to preserve space. After either test, the boot must retain an interior height of one-half inch for men's boots or 15/32 of an inch for women's boots.

This clearance is the safety zone that prevents the toe cap from crushing the wearer's toes, which is the entire purpose of the design.

Understanding the Trade-offs: Material Choices

While all ASTM-certified boots pass the same performance tests, the material used for the toe cap introduces different characteristics that affect comfort and secondary safety features.

Steel Toes

Steel is the traditional material for safety toes. It is exceptionally strong and offers proven protection.

However, steel is the heaviest option and can conduct heat and cold, which can be a drawback in extreme temperature environments.

Composite Toes

Composite toes are made from non-metallic materials like carbon fiber, plastic, or Kevlar. Their primary advantage is their lighter weight.

Because they are non-metallic, they do not conduct electricity or temperature, making them ideal for electricians or workers in very hot or cold conditions.

Alloy Toes

Alloy toes, often made from lightweight metals like aluminum or titanium, offer a compromise between steel and composite.

They provide the strength of metal but are significantly lighter than steel. They can be made thinner than steel caps, resulting in a less bulky toe box.

Making the Right Choice for Your Needs

The material of the toe cap doesn't change the basic level of ASTM-rated protection, but it does impact the boot's weight, comfort, and suitability for specific job sites.

- If your primary focus is proven protection at a lower cost: Steel toes are the traditional and highly effective industry standard.

- If your primary focus is lightweight comfort and non-conductivity: Composite toes are ideal for long days on your feet or in environments with electrical hazards or extreme temperatures.

- If your primary focus is a balance of light weight and a less bulky fit: Alloy toes offer metallic protection in a lighter package than steel.

Ultimately, choosing the right boot means matching the toe cap's properties to the unique demands of your work environment.

Summary Table:

| Design Feature | Purpose & Requirement |

|---|---|

| Toe Cap Material | Steel, composite, or alloy shell integrated into the boot's structure. |

| Impact Test (I/75) | Must withstand a 75 foot-pound force impact. |

| Compression Test (C/75) | Must withstand 2,500 pounds of steady pressure. |

| Critical Clearance | Must maintain a minimum safe space (e.g., 0.5 inches) inside the cap after testing. |

Need ASTM F2413-compliant safety boots for your team? As a large-scale manufacturer, 3515 produces a comprehensive range of certified footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective boots designed to meet rigorous safety standards. Contact us today to discuss your specific requirements and benefit from our high-volume manufacturing expertise.

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

People Also Ask

- Why are Force Sensing Resistor (FSR) sensors core for Safety Shoes? Ensure Workplace Compliance with Smart Tech

- How do integrated sensor systems contribute to the objective measurement of wearable industrial products? Unlock Verifiable Performance and Safety.

- What is the technical necessity of safety shoes in automated detection for tower maintenance? Ensure 100% PPE Compliance

- How do the soles of firefighter boots perform under heat? Engineered for Melt-Resistant Safety

- What are the different types of fastening systems for motorcycle boots? Find Your Perfect Fit & Security

- What is the first step in selecting protective footwear? Start with a Hazard Assessment

- How do industrial safety shoes contribute to safety in sugar production? Ensure High-Altitude Inspection Security

- What should employers consider when selecting safety footwear? A Guide to Risk-Based Selection