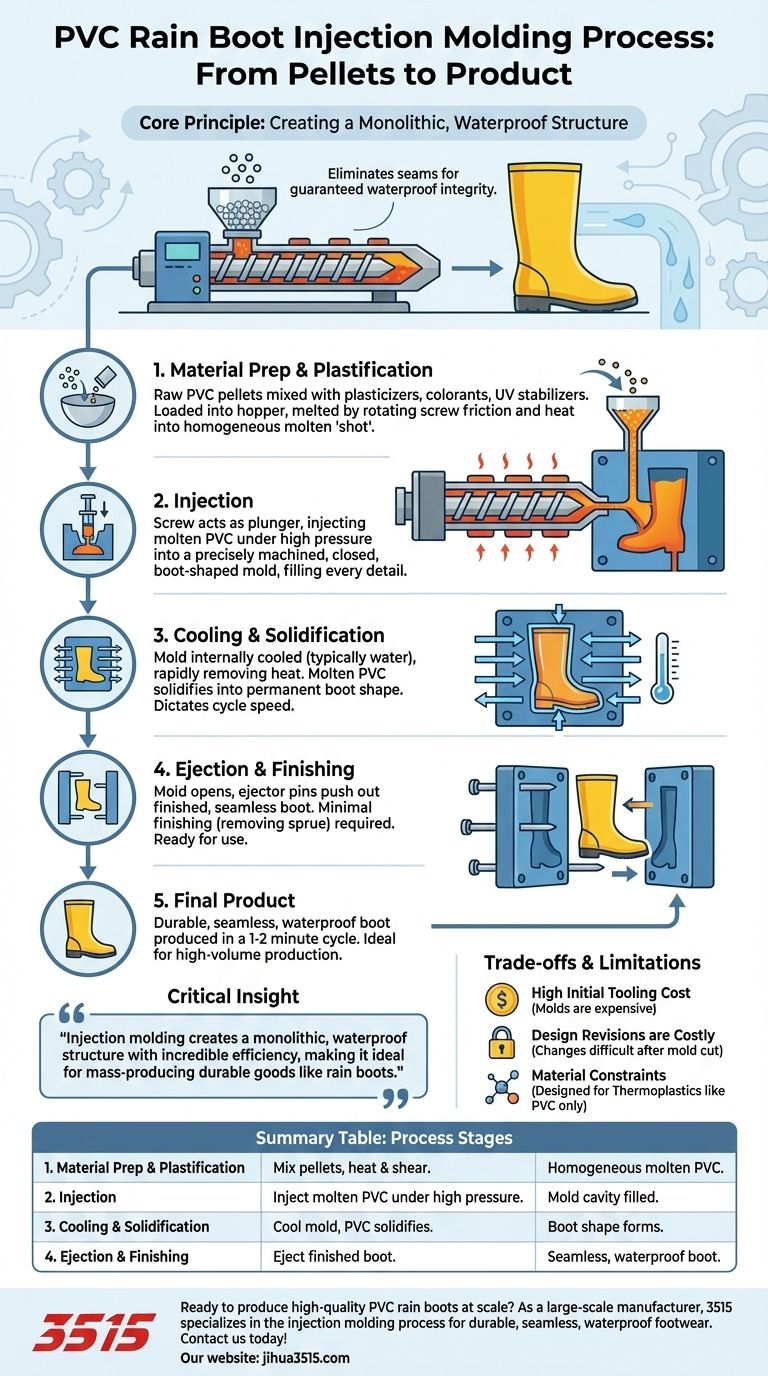

At its core, the injection molding process for PVC rain boots is a high-speed manufacturing method that transforms raw plastic pellets into a complete, seamless, and waterproof boot in a single automated operation. Under immense heat and pressure, molten Polyvinyl Chloride (PVC) is forced into a precisely machined boot-shaped mold, where it cools and solidifies.

The critical insight is that injection molding is not just a way to shape plastic; it's a method for creating a monolithic, waterproof structure with incredible efficiency and consistency, making it the ideal process for mass-producing durable goods like rain boots.

The Core Principle: From Granules to a Finished Boot

The fundamental challenge in making a rain boot is ensuring it is completely impervious to water. Traditional methods that involve stitching or gluing create seams, which are potential points of failure and leakage.

Injection molding solves this by forming the entire boot—sole, upper, and heel—as one continuous piece of material. This eliminates seams entirely, guaranteeing a waterproof final product directly from the mold.

A Step-by-Step Breakdown of the Process

The entire cycle, from loading raw material to ejecting a finished boot, can take as little as one to two minutes, allowing for massive production scale. Each stage is critical for the final quality of the boot.

Step 1: Material Preparation

Before the process begins, raw PVC pellets are often mixed with additives. These can include plasticizers to control flexibility, colorants for aesthetics, and UV stabilizers to prevent degradation from sunlight. This mixture is then loaded into a hopper on the injection molding machine.

Step 2: Plastification (Melting)

The PVC granules are fed from the hopper into a heated barrel containing a large rotating screw. As the screw turns, it simultaneously pushes the pellets forward and generates intense friction and heat. This, combined with external heating bands, melts the PVC into a homogenous, molten liquid known as the "shot."

Step 3: Injection

Once a sufficient amount of molten PVC has accumulated at the front of the barrel, the screw acts like a plunger. It thrusts forward at high pressure, injecting the molten plastic shot into a closed, temperature-controlled mold. The pressure ensures the liquid PVC completely fills every detail of the boot-shaped cavity, from the tread on the sole to any logos on the side.

Step 4: Cooling and Solidification

The mold is internally cooled, typically with circulating water. This rapidly removes heat from the molten PVC, causing it to solidify and take the permanent shape of the mold. This cooling phase is often the longest part of the cycle and dictates the overall production speed.

Step 5: Ejection and Finishing

After the PVC has solidified, the mold opens, and the finished rain boot is pushed out by ejector pins. At this point, the boot is fully formed and functional. The only finishing step required is typically the removal of a small piece of excess material (the "sprue") where the plastic was injected into the mold.

Understanding the Trade-offs and Limitations

While highly effective, injection molding is not without its specific constraints. Understanding these is key to leveraging the process correctly.

High Initial Tooling Cost

The primary drawback is the cost of the mold, also known as the "tool." Molds are complex pieces of hardened steel, and their design and fabrication can be extremely expensive, often running into tens of thousands of dollars or more. This makes the process suitable only for high-volume production where the cost can be spread across many units.

Design Revisions are Costly

Once a steel mold is cut, making changes is difficult and expensive. The design of the boot must be completely finalized before tooling begins. Modifying a mold is a significant engineering undertaking, unlike the flexibility offered by prototyping methods.

Material Constraints

Injection molding is designed for thermoplastics—polymers that can be melted and cooled repeatedly. While PVC is an excellent and versatile choice, this process is not suitable for materials like natural rubber or thermosetting plastics, which cannot be re-melted once cured.

Making the Right Choice for Your Goal

Applying this knowledge depends entirely on your project's priorities.

- If your primary focus is mass production and cost-efficiency: Injection molding is unmatched for high volumes, as the low cost per boot quickly offsets the initial high tooling investment.

- If your primary focus is a seamless, waterproof design: The monolithic nature of an injection-molded part makes it the superior choice for creating a product that is inherently free of leaks.

- If your primary focus is rapid prototyping or low-volume production: The high cost of tooling makes injection molding impractical; 3D printing or other fabrication methods would be more suitable for initial models.

Ultimately, the injection molding process provides a powerful and efficient path from raw material to a finished, reliable product.

Summary Table:

| Stage | Key Action | Outcome |

|---|---|---|

| 1. Material Prep | Mix PVC pellets with plasticizers, colorants. | Ready-to-melt compound. |

| 2. Plastification | Heat and shear pellets in a barrel with a screw. | Homogeneous molten PVC. |

| 3. Injection | Inject molten PVC under high pressure into a mold. | Mold cavity is completely filled. |

| 4. Cooling | Cool the mold with circulating water. | PVC solidifies into boot shape. |

| 5. Ejection | Open mold and eject the finished boot. | A seamless, waterproof boot is produced. |

Ready to produce high-quality PVC rain boots at scale?

As a large-scale manufacturer, 3515 specializes in the injection molding process to deliver durable, seamless, and completely waterproof footwear. We produce a comprehensive range of boots for distributors, brand owners, and bulk clients, ensuring efficiency and consistency for your high-volume needs.

Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Durable Waterproof Rain Boots | Custom Manufacturer for Wholesale & Brands

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Insulated Safety Boots and Shoes for Wholesale & Bulk Orders

People Also Ask

- Why is it harmful to use detergent alone on rubber boots? Protect Your Footwear Investment

- What is the cultural impact of Wellington boots? From Battlefields to Fashion Runways

- Why are wellies problematic for children with low muscle tone or mobility issues? Find Safe, Supportive Alternatives

- What is vulcanization and why is it important in gumboot manufacturing? Unlock Superior Durability & Performance

- How can parents measure a baby's feet to choose the right size of wellies? A Step-by-Step Guide

- Why do gardeners prefer rubber boots? Unbeatable Protection for Your Garden Work

- What makes wellies essential for camping trips? The Ultimate Guide to Dry Feet & Campsite Convenience

- Who popularized the Wellington boot and how did it get its name? A Story of Practical Design