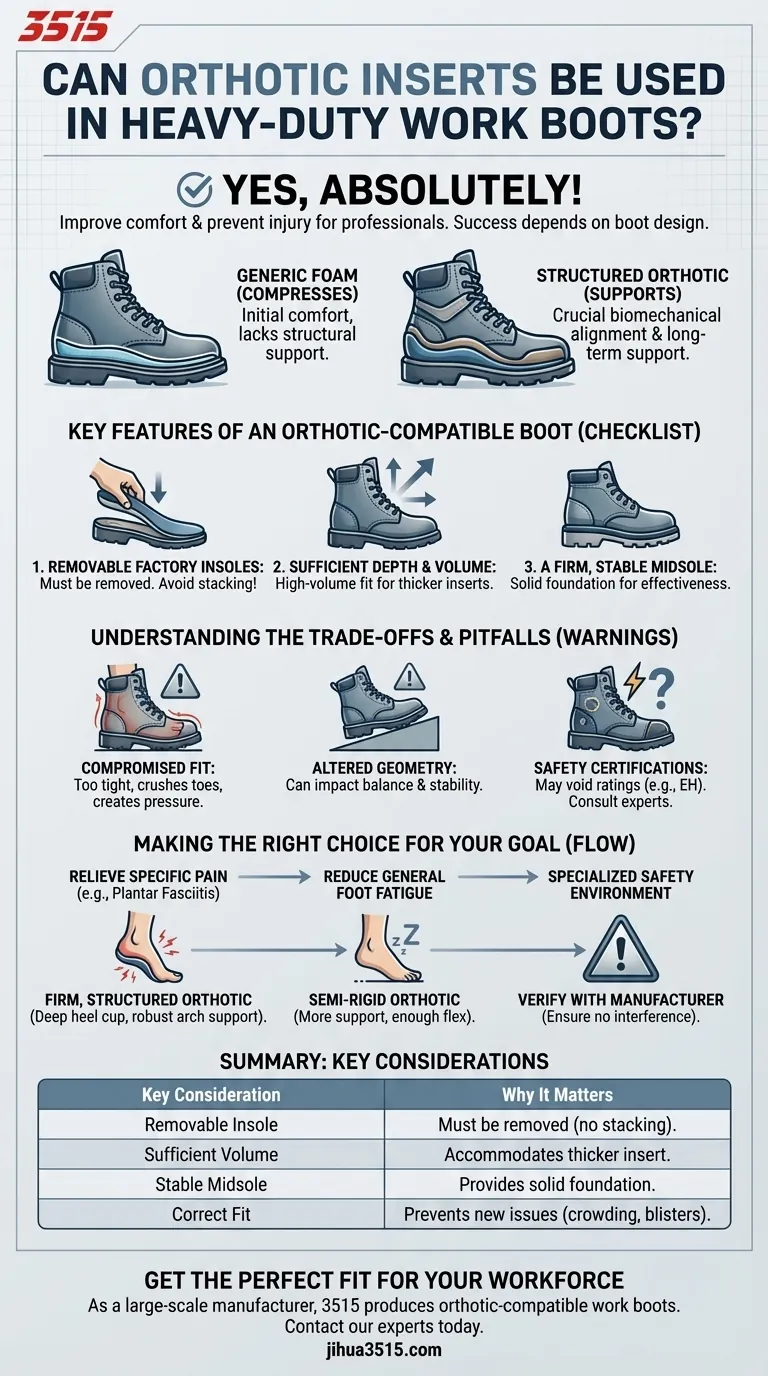

Yes, you absolutely can use orthotic inserts in heavy-duty work boots, and for many professionals who spend all day on their feet, it is the most effective way to improve comfort and prevent injury. However, success depends entirely on the boot's design. The key is ensuring the boot has a removable factory insole and enough internal volume to accommodate the orthotic without compromising the fit.

While factory insoles provide basic cushioning, a proper orthotic offers crucial biomechanical support. The goal is not just to add a layer, but to replace the generic factory liner with a structured insert that correctly aligns your foot within the boot's protective shell.

Why Standard Boot Insoles Often Fall Short

Most work boots come with a generic, compressible foam insole. Its primary job is to provide initial step-in comfort, not long-term structural support for your foot's unique architecture.

The Problem with Generic Cushioning

A standard insole is designed for the "average" foot, which fits almost no one perfectly. It lacks the rigid support needed to control pronation (foot rolling inward) or support a high arch.

From Cushion to Collapse

Over a long workday, this generic foam compresses under your body weight. This reduces its shock absorption and leaves your foot's arches and joints without the stable foundation they need to prevent fatigue and strain.

Key Features of an Orthotic-Compatible Work Boot

Before you invest in an orthotic, you must first verify that your boot can properly accommodate it. Trying to force an insert into an incompatible boot will create more problems than it solves.

Removable Factory Insoles

This is the most critical feature. The factory insole must be removed before you insert your orthotic. Placing an orthotic on top of the existing insole will raise your heel too high, crowd your toes, and destabilize your foot.

Sufficient Depth and Volume

Orthotics, especially supportive ones, are thicker and take up more space than the flimsy insoles they replace. Look for boots described as having a "high-volume" fit or a deep footbed to ensure you have enough room.

A Firm, Stable Midsole

An orthotic needs a solid base to work effectively. If the boot itself can be easily twisted or bent in the middle, the orthotic won't be able to provide consistent support. The boot's structure is the foundation for the orthotic.

Understanding the Trade-offs and Pitfalls

While highly beneficial, introducing an orthotic into your work boot requires careful attention to detail. An improper setup can negate the benefits and introduce new risks.

Compromising the Fit

The most common mistake is creating a fit that is too tight. An orthotic that is too thick for your boot will crush your toes, create painful pressure points, and can even lead to blisters or nerve impingement. The boot should feel snug, not restrictive.

Altering the Boot's Geometry

A correctly fitted orthotic should place your foot in a neutral, stable position. However, an insert that is too thick or has an excessive heel cup can change the boot's geometry, potentially impacting your balance and stability on uneven surfaces.

Impacting Safety Certifications

In some specialized cases, a third-party insert can technically void a boot's safety rating, particularly for Electrical Hazard (EH) protection. If this is a critical requirement for your job, it is best to consult with your boot manufacturer or safety manager about approved orthotic solutions.

Making the Right Choice for Your Goal

Your choice of orthotic should be directly tied to the problem you are trying to solve.

- If your primary focus is relieving specific pain (like plantar fasciitis): You need a firm, structured orthotic with a deep heel cup and robust arch support. Prioritize support over soft cushioning.

- If your primary focus is reducing general foot fatigue: A semi-rigid orthotic is an excellent choice. It provides more support than a foam insole but offers enough flex for all-day comfort.

- If you work in a specialized safety environment: Always verify with the boot manufacturer or a podiatrist that your chosen orthotic will not interfere with the boot's protective features.

Investing in the right support for your feet is investing in your ability to perform your job safely and effectively for the long term.

Summary Table:

| Key Consideration | Why It Matters |

|---|---|

| Removable Insole | Must be removed to fit the orthotic without compromising fit. |

| Sufficient Volume | Boot needs extra depth to accommodate the thicker orthotic insert. |

| Stable Midsole | Provides a solid foundation for the orthotic to work effectively. |

| Correct Fit | Prevents new issues like toe crowding, blisters, or instability. |

Get the Perfect Fit for Your Workforce

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety and work boots, including designs optimized to accommodate orthotic inserts for superior comfort and support.

We can help you provide footwear that meets the specific needs of professionals who spend all day on their feet. Contact our experts today to discuss your requirements and discover how we can support your business.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene