Under OSHA regulations, protective footwear is mandated in any work environment where an employee's feet are exposed to specific, identifiable dangers. This requirement is triggered by the presence of hazards such as falling or rolling objects, materials that could pierce the sole of a shoe, and various electrical risks.

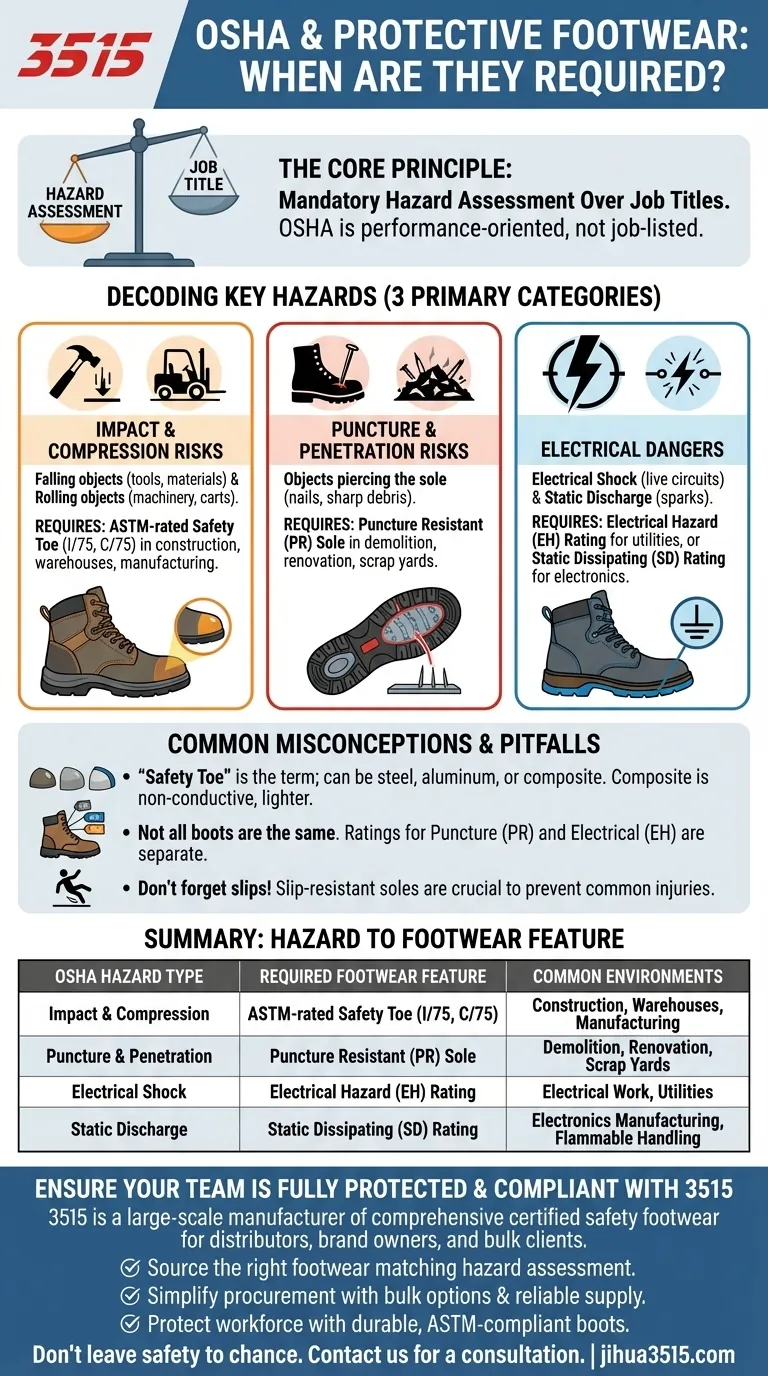

The core principle of OSHA's rule is not based on job titles but on a mandatory hazard assessment. If your workplace presents risks from impact, compression, punctures, or electrical hazards, then compliant protective footwear is non-negotiable.

The Core Principle: Hazard Assessment Over Job Title

OSHA’s standard for personal protective equipment (PPE) is performance-oriented. This means it doesn't provide a list of jobs that require safety boots.

Instead, the regulation places the responsibility on the employer to assess the workplace for potential dangers. If those dangers exist, the employer must ensure workers use appropriate protective footwear.

This is a critical distinction. A warehouse worker will almost certainly need them, but so might an IT professional who occasionally has to move heavy server equipment in a data center. The decision is always driven by the specific task and its environment.

Decoding OSHA's Key Foot Hazards

To determine if protective footwear is required, you must assess the environment for the specific risks OSHA outlines. These fall into three primary categories.

Impact and Compression Risks

This is the most common reason for requiring safety-toed footwear. The steel or composite toe cap is designed as a barrier against crushing forces.

These risks are present when dealing with falling objects, such as tools or materials dropped from a height on a construction site.

They also include rolling objects, a common hazard in warehouses with forklifts, logistics centers with heavy carts, or any environment where heavy machinery or materials could roll over a worker's foot.

Puncture and Penetration Risks

This hazard involves objects that could pierce the sole of a standard shoe, causing serious injury.

Work environments like demolition sites, scrap yards, or renovation projects with exposed nails and sharp debris are prime examples.

For these situations, a simple steel toe is not enough. The footwear must also have a puncture-resistant plate integrated into the sole to provide adequate protection.

Electrical Dangers

Protective footwear can also be a critical defense against electrical hazards, which come in two distinct forms.

The first is protection against electrical shock from live circuits. Boots with an Electrical Hazard (EH) rating have non-conductive soles that can insulate a worker from the ground, preventing a deadly circuit from being completed.

The second is mitigating static discharge. In environments with sensitive electronics or flammable materials, a static spark can be catastrophic. Static Dissipating (SD) footwear is designed to safely channel static electricity from the body to the ground, preventing buildup.

Common Misconceptions and Pitfalls

A proper hazard assessment requires understanding the nuances of protective footwear. Simply mandating "steel toe boots" can leave your team exposed to other dangers.

"Safety Toe" is the Correct Term

While "steel toe" is the common term, the protective cap can be made from steel, aluminum, or composite materials. All are acceptable as long as they meet the required ASTM International standards for impact and compression.

Composite toes are often lighter, don't conduct cold as easily, and won't set off metal detectors, making them better for certain environments.

Not All Safety Boots Are the Same

A standard safety-toe boot does not automatically protect against punctures or electrical hazards. These are separate features indicated by specific ratings (like PR for Puncture Resistance or EH for Electrical Hazard).

Failing to match the boot's specific ratings to the identified hazards is a common and dangerous compliance gap. The boot must be rated for the specific risks present.

Forgetting About Slips, Trips, and Falls

While OSHA's impact-related rules are clear, slips, trips, and falls are among the most frequent causes of all workplace injuries.

A comprehensive foot protection program must also consider the need for slip-resistant soles. A boot that protects from a falling object is of little use if its wearer slips and falls while carrying it.

Making the Right Choice for Your Environment

Your footwear selection must be directly linked to the results of your hazard assessment. Use the specific risks you've identified to guide your choice.

- If your primary focus is heavy materials handling: Ensure the footwear meets the ASTM standards for impact (I/75) and compression (C/75).

- If your primary focus is demolition or sites with debris: Select footwear with a Puncture Resistant (PR) rating in addition to a safety toe.

- If your primary focus is working near live electrical circuits: You must require boots with a specific Electrical Hazard (EH) rating.

- If your primary focus is preventing static sparks: Mandate the use of Static Dissipating (SD) rated footwear to protect sensitive components or prevent ignition.

Ultimately, a thorough and documented hazard assessment is the only definitive way to ensure compliance and, more importantly, protect your team from harm.

Summary Table:

| OSHA Hazard Type | Required Footwear Feature | Common Work Environments |

|---|---|---|

| Impact & Compression | ASTM-rated Safety Toe (I/75, C/75) | Construction, Warehouses, Manufacturing |

| Puncture & Penetration | Puncture Resistant (PR) Sole | Demolition, Renovation, Scrap Yards |

| Electrical Shock | Electrical Hazard (EH) Rating | Electrical Work, Utilities |

| Static Discharge | Static Dissipating (SD) Rating | Electronics Manufacturing, Flammable Material Handling |

Ensure Your Team is Fully Protected and OSHA-Compliant

Navigating OSHA's performance-based regulations can be complex. As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of compliant boots and shoes, from standard safety toes to specialized EH and PR models.

We help you:

- Source the right footwear that precisely matches your hazard assessment findings.

- Simplify procurement with bulk ordering options and reliable supply chains.

- Protect your workforce with durable, high-quality boots built to meet ASTM standards.

Don't leave safety to chance. Contact our team today for a consultation on your protective footwear needs.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium KPU Injection Athletic Style Safety Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- Are steel toe shoes unsafe for electricians? Debunking the EH-Rated Footwear Myth

- What are the key benefits of modern steel toe boots? Achieve Maximum Safety & Durability

- What are the benefits of steel-toe boots in terms of impact resistance? Get Maximum Protection for Your Workforce

- Is the myth about steel toe shoes cutting off toes true? Debunking the Safety Footwear Myth

- What are the primary benefits of steel toe boots? Maximum Impact Protection for Your Workforce

- What is the alternative to steel toed boots that is lighter but still safety approved? Compare Composite & Alloy Toes

- What are steel-toed shoes and what industries use them? Essential Foot Protection for Hazardous Work

- What are the impact and compression requirements for safety toe boots? Essential Standards for Worker Protection