For discerning footwear buyers, the term "Goodyear welt" signals quality—but what justifies its premium price? This construction method isn’t just about prestige; it’s engineered to outlast alternatives while offering repairability that reduces long-term costs. Let’s dissect how this centuries-old technique delivers tangible value through durability, comfort, and craftsmanship.

Goodyear Welt Construction: A Benchmark in Shoemaking

Unlike cemented or Blake-stitched shoes, Goodyear welt construction creates a robust bond between the upper and sole via an intermediary leather strip (the welt). This design allows repeated resoling without damaging the shoe’s structure, extending its lifespan to decades with proper care.

Anatomy of the Process: From Insole to Finishing

Insole Preparation: The Foundation of Structural Integrity

The process begins with a rigid leather insole, which is grooved to accommodate stitching. A canvas rib is cemented to its edge, forming the anchor point for the welt. This foundational step ensures the shoe maintains its shape under stress.

Welt Stitching: The Art of Joining Upper and Sole

A strip of leather (the welt) is stitched to the upper and canvas rib, creating a flexible yet durable connection. Research shows this triple-layer bond—upper, welt, and rib—distributes tension evenly, preventing premature wear at stress points.

Cork Filling: Dynamic Comfort Over Time

Between the insole and outsole, a layer of resinated cork molds to the wearer’s foot within weeks, offering personalized arch support. Unlike synthetic foams that compress permanently, cork retains resilience, adapting to gait changes over years.

Why This Method Outlasts Alternatives

Comparative Durability: Goodyear vs. Blake vs. Cemented

- Goodyear Welt: The welt acts as a sacrificial layer; when soles wear out, only the welt-sole stitches are replaced. Brands like Crockett & Jones use this for heavy-duty boots.

- Blake Stitch: Direct stitching of the sole to the insole makes shoes lighter but compromises water resistance and resoleability.

- Cemented Construction: Adhesive-bonded soles are cost-effective but often fail after 1–2 years, as delamination is irreversible.

The Resoleability Advantage: Reducing Long-Term Costs

A single resole (costing a fraction of a new pair) can extend a Goodyear welt shoe’s life by 5–10 years. For bulk buyers like distributors, this translates to lower replacement frequency and higher ROI per unit.

Maintaining Goodyear Welt Shoes: Preserving Craftsmanship

- Rotate Pairs: Allow 24 hours between wears for cork to rebound.

- Use Shoe Trees: Cedar trees absorb moisture and maintain toe shape.

- Resole Proactively: Replace soles before wear reaches the welt stitching.

Upgrade Your Inventory with 3515’s Goodyear Welt Footwear

For distributors and brand owners seeking durable, repairable footwear, 3515 combines traditional craftsmanship with modern efficiency. Our Goodyear welt shoes offer bulk clients a cost-per-wear advantage, ensuring customer satisfaction and repeat orders.

By investing in Goodyear welt construction, you’re not just buying shoes—you’re investing in a legacy of durability. Whether for work boots or dress shoes, this method proves its worth every step of the way.

Related Products

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

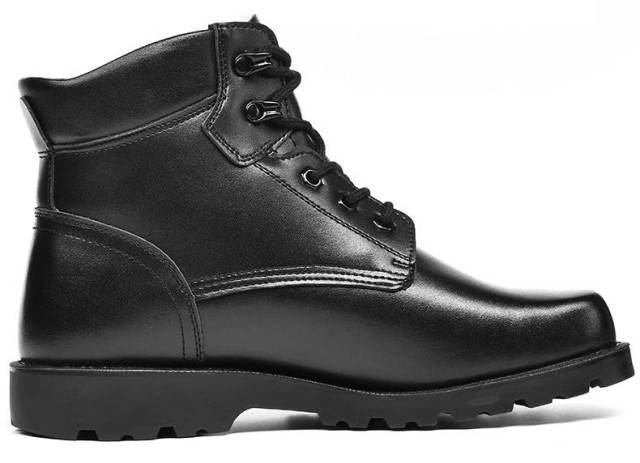

- Wholesale Durable 6-Inch Work Boots | Custom & Private Label Manufacturer

- Wholesale Classic Leather Lace-Up Ankle Boots for Brand Manufacturing

- Wholesale Customizable Suede Safety Boots - Puncture-Proof with Velcro Closure

- Durable High-Traction Canvas Sneakers Wholesale & Custom Manufacturing

Related Articles

- How Work Boot Upper Materials Prevent Foot Injuries and Boost Comfort

- How Work Boot Safety Features Counteract Industry-Specific Workplace Hazards

- How Lace-Up Work Boots Solve Workplace Safety Challenges

- How to Choose Work Boot Materials: Balancing Weight, Safety, and Job-Specific Needs

- How to Solve Work Boot Discomfort Without Sacrificing Safety or Durability