Winter demands footwear that adapts to constantly shifting ground conditions—from slick urban pavements to unstable mountain trails. The engineering behind snow boot outsoles combines material science with biomechanics to create reliable traction systems. Let’s examine how these designs address specific winter challenges and how to match them to your needs.

The Science of Winter Traction

Material Composition and Cold-Weather Flexibility

Outsole materials must balance hardness for durability with flexibility for grip. Research shows that overly rigid rubber becomes brittle in sub-zero temperatures, reducing surface contact. Conversely, softer compounds (like vulcanized rubber) maintain pliability, conforming to uneven terrain for better friction.

Key considerations:

- Temperature thresholds: Optimal rubber formulations retain elasticity below -20°C.

- Hydrophobic properties: Materials that repel water minimize ice adhesion.

Tread Patterns: Geometry vs. Surface Interaction

Tread design dictates how boots channel snow, displace water, or bite into ice:

- Multi-directional lugs (angled grooves) prevent lateral slipping on slopes.

- Micro-treads (tight, shallow patterns) excel on packed snow, while deep lugs (6–8mm) claw through loose powder.

- Siping (thin slits in rubber) increases edges for ice contact, akin to tire treads.

Real-World Performance Breakdown

Case Study: Urban Ice vs. Mountain Snow Trails

- Urban settings: Boots with densely spaced sipes and moderate lugs (3–5mm) outperform on polished ice, as seen in ASTM F2913 slip-resistance tests.

- Backcountry terrain: Aggressive, self-cleaning lugs prevent snowballing underfoot, critical for steep ascents.

How Brands Test Outsole Effectiveness

The ASTM F2913 standard evaluates slip resistance on wet/icy surfaces. Top-performing outsoles achieve:

- Coefficient of friction (COF): ≥0.4 on ice (qualifying as "high traction").

- Abrasion resistance: Maintains grip after miles of use.

Choosing Your Grip Profile

When Deep Lugs Outperform Micro-Treads

Prioritize deep lugs if you:

- Trek through fresh snow or mud.

- Need uphill propulsion (lugs act like cleats).

Micro-treads suit:

- Daily commutes on compacted snow.

- Mixed surfaces (e.g., transitioning from pavement to icy stairs).

The Role of Heel Braking Zones in Slope Descents

Boots designed for alpine use often feature:

- Extended heel lugs: Absorb impact during downhill steps.

- Staggered treads: Slow momentum by increasing ground contact time.

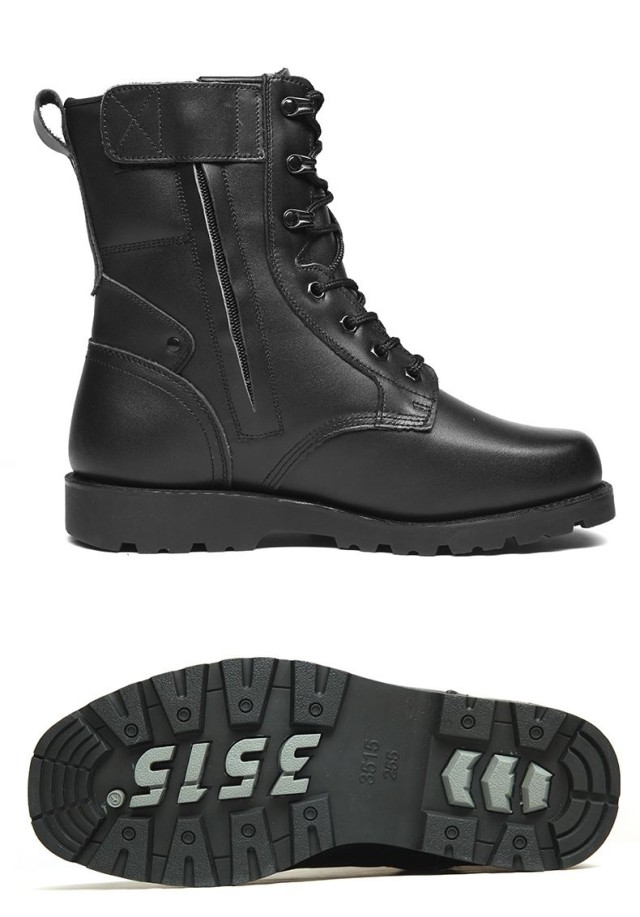

Ready to equip your clients with winter-ready footwear? 3515 partners with distributors and brands to deliver engineered outsoles for every winter scenario—from city streets to backcountry expeditions. [Contact us] to discuss bulk solutions tailored to your market’s demands.

Engineered traction isn’t just about materials—it’s about understanding how each element works in harmony to keep you upright.

Related Products

- Durable Steel Toe Safety Boots Wholesale & Custom Manufacturing

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- Wholesale Slip-On Safety Boots Manufacturer - Custom Puncture-Proof & Steel Toe

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

Related Articles

- How Safety Work Boots Engineer Protection: Features and Standards for Targeted Hazard Mitigation

- Matching Men’s Work Shoe Safety Technologies to Workplace Hazards

- How Modern Steel Toe Boots Achieve Safety Without Sacrificing Comfort

- How to Choose Between Steel and Composite Toe Boots for Maximum Safety

- How to Choose Safety Footwear for Electrical Hazard Jobs: Steel Toe vs. Composite Toe