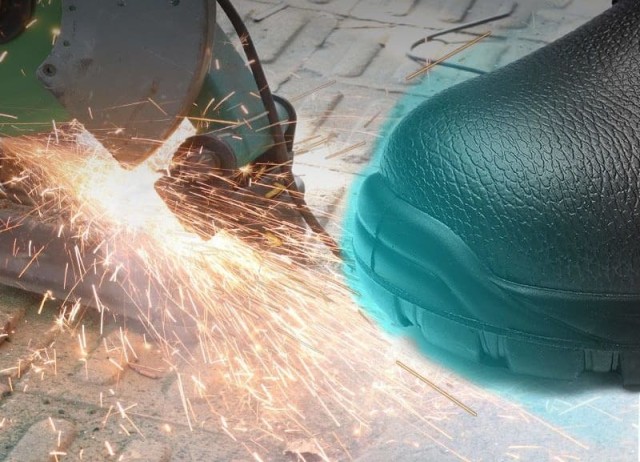

Workplace safety is non-negotiable, especially in industries where cutting hazards are a daily threat. Safety boots are engineered with advanced materials and rigorous testing protocols to mitigate these risks. This article breaks down the technical mechanisms behind cut-resistant footwear, the industry standards that validate their effectiveness, and real-world applications that prove their life-saving potential.

Anatomy of Cutting-Resistant Safety Boots

Cutting hazards demand more than just a sturdy exterior—they require a multi-layered defense system. Modern safety boots integrate three critical components:

-

Reinforced Toe Caps:

- Traditionally made of steel, now increasingly replaced by lightweight composites like fibreglass or Kevlar.

- Designed to withstand impact and compression while reducing fatigue.

-

Cut-Resistant Uppers:

- High-performance materials like ballistic nylon or laminated leather resist abrasion and slicing.

- Some designs incorporate chainmail-like mesh for extreme environments (e.g., forestry or metal fabrication).

-

Puncture-Proof Midsoles:

- Thin but dense layers of metal or composite materials stop sharp objects from penetrating the sole.

Why it matters: A single lapse in foot protection can lead to severe injuries. For example, in construction, a misplaced blade or falling debris can slice through ordinary footwear—but cut-resistant boots act as a shield.

Material Science: From Steel Toe to Composite Armor

The evolution of safety boot materials reflects a balance between protection and practicality:

Traditional vs. Modern Materials

| Material | Pros | Cons |

|---|---|---|

| Steel | High impact resistance | Heavy, conducts temperature |

| Kevlar® | Lightweight, cut-resistant | Less effective against crushing |

| TPU Outsoles | Oil- and slip-resistant | Less durable than rubber |

Key innovations:

- Composite Toe Caps: Fibreglass-reinforced polymers offer steel-level protection at half the weight.

- Multi-Density Outsoles: Rubber compounds with varying hardness levels improve grip and longevity.

Real-world insight: Workers in oil refineries, for instance, benefit from boots with nitrile rubber soles—resistant to chemicals and heat—while warehouse staff prioritize lightweight TPU for all-day comfort.

Industry Standards and Testing Protocols

Safety boots aren’t effective unless they meet certified benchmarks. Globally recognized standards include:

- ASTM F2412/F2413: Tests for impact resistance (e.g., a 75-lb weight dropped from 1 foot) and compression (2,500 lbs of force).

- ISO 20345: Evaluates toe cap integrity and slip resistance under EU regulations.

- EN ISO 22568: Focuses on chainmail protection for forestry boots.

Did you know? Boots labeled "ASTM F2413-18 I/75 C/75" have passed impact (75 ft-lbs) and compression (2,500 lbs) tests. Such granular ratings help employers match footwear to specific hazards.

Case Studies: Reducing Injuries in High-Risk Sectors

1. Manufacturing Plants

- A 2022 study in automotive factories showed a 40% drop in foot lacerations after switching to boots with Kevlar-lined uppers.

2. Construction Sites

- Steel-toe boots with puncture-resistant midsoles reduced nail-related injuries by over 60% in a U.S. highway project.

3. Agriculture

- Chainmail-reinforced boots prevented 90% of cutting injuries among forestry workers handling chainsaws.

The takeaway: Investing in certified safety boots isn’t just compliance—it’s a measurable ROI in workforce health and productivity.

Step Into Safety with 3515

Whether you’re a distributor sourcing bulk orders or a brand owner seeking custom designs, 3515 delivers safety boots engineered for real-world hazards. Our expertise spans materials, certifications, and sector-specific solutions—ensuring every pair meets the highest standards.

Ready to upgrade your safety footwear? Partner with 3515 to equip your team with boots that blend cutting-edge protection with all-day comfort.

By understanding the science and standards behind cut-resistant safety boots, businesses can make informed choices that protect their most valuable asset: their people. From composite armors to rigorous testing, these technologies quietly redefine workplace safety—one step at a time.

Related Products

- Wholesale Customizable Suede Safety Boots - Puncture-Proof with Velcro Closure

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

- Wholesale Durable 6-Inch Work Boots | Custom & Private Label Manufacturer

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Wholesale Durable Mid-Cut Tactical Boots for Custom & Private Label Brands

Related Articles

- Work Boots vs. Western Boots: How to Choose the Right Footwear for Labor Safety

- Steel Toe Work Boots: Balancing Safety and Comfort for Demanding Jobs

- How to Choose Work Boots That Match Your Industry's Safety Needs

- How to Choose Work Boot Materials for Maximum Safety and Durability

- How to Choose Work Boots That Balance Safety, Comfort, and Durability for Your Job