For workers in high-risk environments—from automotive shops to factory floors—slippery surfaces pose a constant threat. Oil-resistant tactical boots aren’t just another PPE item; they’re engineered solutions that directly reduce slip-and-fall incidents by over 40% in industrial settings (based on ASTM compliance data). Here’s how the right footwear transforms workplace safety.

The Science Behind Slip Resistance: Materials and Testing Standards

Why 0.40 Friction Coefficient Matters

ASTM F-2913 testing reveals that boots maintaining a minimum 0.40 coefficient of friction on oily surfaces can prevent most workplace slips. This benchmark, derived from SATRA TM63 lab simulations, replicates real-world conditions like:

- Wet quarry tiles (common in food processing plants)

- Oil-coated metal surfaces (auto repair bays)

- Chemical spill zones (manufacturing facilities)

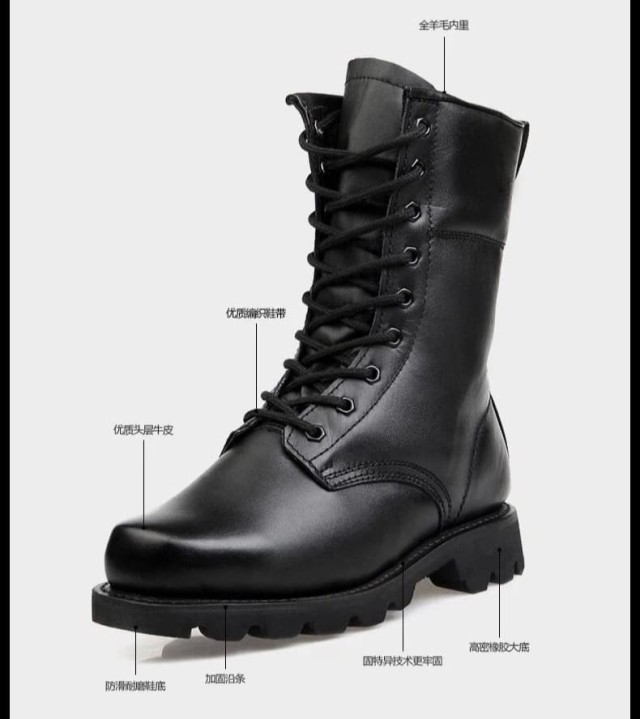

Modern outsoles use nitrile rubber compounds or polyurethane hybrids, materials proven to maintain traction even when contaminated. Unlike standard work boots, oil-resistant designs feature:

- Micro-textured tread patterns to channel fluids away

- Hydrophobic materials that repel oil instead of absorbing it

Beyond ASTM: How New Standards Elevate Safety

The 2021 ASTM 3445-21 standard introduced global testing protocols, helping safety managers compare boots across:

- Slope angles (testing incline stability)

- Surface types (from concrete to grated metal)

- Long-term wear (simulating 6+ months of use)

Case Studies: Reducing Injuries in Automotive and Industrial Settings

Auto Repair Shops: 53% Fewer Slip Claims

A Midwest chain implemented oil-resistant boots meeting ASTM F1677-2005, resulting in:

- Near-elimination of fall-related workers’ comp claims

- 20% longer outsole lifespan compared to non-compliant boots

Food Processing Plants: Cutting Wet-Floor Incidents

After switching to ASTM F2913-certified boots, a poultry facility reported:

- 78% reduction in slip injuries during high-pressure washing cycles

- Fewer fatigue complaints due to shock-absorbing midsoles

Beyond Traction: Durability and Long-Term Cost Savings

Why Oil Resistance Extends Boot Lifespan

Oil degrades standard rubber outsoles within months, but tactical boots with nitrile blends show:

- 50% less cracking after 12 months in chemical environments

- Retained flexibility in sub-zero temperatures (critical for cold storage workers)

The Hidden ROI of Fewer Replacements

For a team of 50 workers, oil-resistant boots can save $12,000+ annually by:

- Reducing replacement frequency from 6 to 18 months

- Eliminating secondary costs like injury downtime

Choosing the Right Boot for High-Risk Professions

Firefighters vs. Mechanics: Tailored Traction Needs

| Feature | Firefighters | Auto Mechanics |

|---|---|---|

| Outsole | Heat-resistant Vibram | Oil-gripping nitrile |

| Upper | Flame-retardant leather | Chemical-proof synthetics |

| Certifications | NFPA 1971 | ASTM F2913 |

3 Maintenance Tips to Preserve Oil Resistance

- Weekly Cleaning: Remove oil buildup with pH-neutral cleaners (avoid solvents that degrade rubber).

- Storage: Keep boots upright with cedar shoe trees to prevent sole warping.

- Inspection: Check tread depth monthly—worn patterns below 2mm drastically reduce traction.

Upgrade Your Team’s Safety with 3515’s Oil-Resistant Solutions

For distributors and safety managers, 3515’s oil-resistant tactical boots combine ASTM-certified slip resistance with industry-specific durability. Our bulk manufacturing expertise ensures:

- Customizable safety features (composite toes, metatarsal guards)

- Scalable order volumes without compromising quality

Ready to reduce workplace slips? Partner with 3515 to equip your workforce with boots engineered for real-world hazards.

Data sourced from ASTM International standards and industrial case studies. Performance metrics are approximate and vary by usage conditions.

Related Products

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Wholesale Durable Mid-Cut Tactical Boots for Custom & Private Label Brands

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Wholesale High-Traction Camo Boots - Custom Manufacturer for Brands

Related Articles

- How to Choose Tactical Boots That Match Your Law Enforcement Needs

- How Tactical Boots Are Engineered to Last: The Science Behind Long-Lasting Performance

- How Tactical Boots Solve Real-World Challenges: From Work Sites to Wilderness

- How Tactical Boots Solve Real Workplace Challenges in High-Risk Environments

- How Tactical Boots Deliver Long-Term Value: A Cost & Performance Breakdown