For professionals who spend long hours on their feet, work boots must deliver two non-negotiable benefits: absolute safety and all-day comfort. Advances in material science and ergonomic design now allow modern safety footwear to exceed traditional trade-offs between protection and wearability. This article explores the engineering breakthroughs that make this possible and provides actionable insights for selecting the right boots for your workplace.

Safety Meets Comfort: The Science Behind Work Boot Design

Material Innovations: From Steel Toes to Advanced Composites

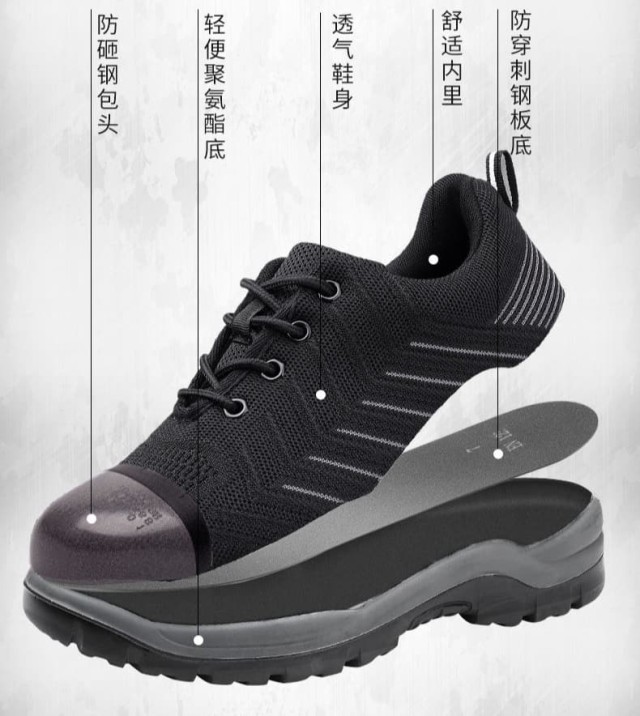

The evolution from traditional steel toes to composite materials illustrates how safety footwear has transformed. While steel toes remain a cost-effective choice for heavy-impact protection, composite alternatives (often made from Kevlar®, carbon fiber, or plastic polymers) offer distinct advantages:

- Weight Reduction: Composite toes can be up to 30% lighter than steel, reducing leg fatigue during extended wear.

- Thermal Insulation: Unlike metal, composites don’t conduct extreme temperatures, keeping feet comfortable in freezing or high-heat environments.

- Electrical Safety: Non-conductive materials prevent electrical hazards—a critical feature for electricians or utility workers.

However, steel toes still dominate in industries requiring maximum durability against crushing forces, such as construction or mining.

Ergonomic Engineering: Lightweight Designs for All-Day Wear

Modern work boots integrate biomechanical research to minimize strain:

- Memory Foam Insoles: Adapt to the foot’s shape, providing personalized cushioning that reduces pressure points.

- Arched Support Systems: Redistribute weight evenly to prevent plantar fasciitis and lower back pain.

- Flexible Midsoles: Allow natural foot movement without compromising puncture resistance.

Technologies like Gore-Tex® linings further enhance comfort by offering breathability and waterproofing, ensuring feet stay dry in humid conditions.

Matching Safety Features to Workplace Hazards

Electrical Work: How EH-Rated Materials Function

For professionals exposed to live circuits, EH-rated boots (tested to ASTM F2413 standards) are essential. These boots:

- Block Current Flow: Use thick rubber soles and non-conductive uppers to prevent electricity from grounding through the body.

- Withstand Up to 600 Volts: Sufficient for most industrial electrical hazards.

- Display Certification Marks: Look for the CSA White Rectangle with an omega (Ω) symbol, indicating rigorous testing.

Heavy Industry: Puncture Resistance and Weight Distribution

In environments with sharp debris (e.g., manufacturing or demolition), boots with puncture-resistant midsoles—often made from layered Kevlar® or metal plates—protect against nails or glass. Key design considerations include:

- Balanced Weight: Heavy-duty protection shouldn’t equate to cumbersome boots. Advanced polymers maintain strength while keeping boots under 3 lbs.

- Slip-Resistant Outsoles: Oil- and chemical-resistant treads prevent accidents on slick surfaces.

Choosing Your Boot: A Buyer’s Checklist

ASTM Standards Decoded: What F2413 Really Means for You

The ASTM F2413 certification ensures boots meet minimum safety requirements for:

- Impact Resistance: Toe caps must withstand a 75-lb object dropped from 1 foot.

- Compression Resistance: Rated for 2,500 lbs of static pressure.

- Metatarsal Protection: Optional add-ons shield the upper foot from falling objects.

Always verify that boots are labeled with the correct ASTM codes for your industry.

Upgrade Your Workforce’s Safety and Comfort with 3515

As a trusted manufacturer for distributors and bulk buyers, 3515 combines cutting-edge safety technologies with ergonomic designs to create boots that workers want to wear. Whether you need EH-rated footwear for electricians or puncture-resistant soles for construction crews, our scalable production ensures consistent quality across all orders. Partner with us to equip your team with footwear that protects without compromising comfort.

Key Takeaways:

- Composite materials reduce weight and improve thermal/electrical safety.

- EH-rated boots are mandatory for electrical work (ASTM F2413 compliant).

- Prioritize boots with ergonomic features like memory foam and arch support.

Related Products

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

Related Articles

- Steel Toe Work Boots: Balancing Safety and Comfort for Demanding Jobs

- How Steel Toe Boots Meet Industry Safety Standards and Reduce Workplace Injuries

- How Steel Toe Shoes Prevent Injuries: The Science Behind Workplace Safety

- How Modern Steel Toe Boots Combine Safety with All-Day Comfort

- How Steel Toe Shoes Meet Safety Standards and Prevent Workplace Injuries