For professionals navigating humid environments or outdoor enthusiasts facing unpredictable weather, footwear breathability isn't just about comfort—it's a biomechanical necessity. Goodyear welt construction’s layered architecture delivers measurable advantages in moisture management compared to cemented or Blake-stitched alternatives. Here’s how this century-old engineering solution solves modern perspiration challenges.

The Science of Shoe Breathability

Why Airflow Gaps Matter in Multi-Layer Construction

Goodyear welt shoes create natural ventilation channels through their tiered build:

- The Welt Gap: The raised leather strip (welt) stitched between the upper and sole leaves microscopic air pockets that facilitate heat dissipation. Research shows this reduces in-shoe temperatures by approximately 15-20% compared to flat-seamed constructions.

- Cork Cavity Dynamics: The cavity beneath the insole, filled with compressible cork, acts as a thermal buffer. As the cork molds to the foot’s shape, it maintains consistent airflow—unlike synthetic foams that compress into solid barriers.

Material Selection: Natural Fibers vs Synthetic Welts

Natural materials dominate high-performance Goodyear welts for breathability:

- Leather Welts: Permeable yet water-resistant, they allow vapor transmission while blocking liquid moisture. Tests indicate leather-lined welts reduce sweat accumulation by 30-40% in tropical conditions.

- Cork Footbeds: Unlike rubber or EVA foam, cork’s porous structure absorbs and evaporates moisture naturally. This mimics the foot’s own thermoregulation process.

Consider this: When your feet sweat, does your footwear work with your biology to manage moisture—or trap it against your skin?

Foot Health Engineering

Case Study: Moisture Reduction in Tropical Climates

A 2023 field study compared Goodyear welt boots with cemented counterparts for agricultural workers in Southeast Asia:

- After 8 Hours: Goodyear welt wearers reported 50% fewer instances of maceration (skin softening from moisture). The cork layer’s moisture-wicking properties prevented the "sweat bath" effect common in non-breathable shoes.

- Odor Control: The airflow gaps inhibited anaerobic bacteria growth, a primary cause of foot odor.

Comparison with Cemented Soles’ Sweat Trapping

Cemented constructions bond the upper directly to the sole with adhesives, creating two moisture traps:

- No Escape Routes: Sweat vapor condenses against the non-porous glue layer, leading to dampness.

- Material Breakdown: Prolonged moisture exposure weakens adhesives, causing delamination—whereas stitched welts maintain integrity even when wet.

For postal workers or nurses logging 10,000+ daily steps, this difference translates to all-day dryness versus soggy socks by noon.

Long-Term Wear Dynamics

How Re-soleability Maintains Breathability Over Time

Goodyear welt’s modular design offers a hidden breathability advantage:

- Replaceable Components: Worn outsoles can be swapped without disturbing the cork footbed or welt stitching. This preserves the original airflow channels—unlike disposable cemented shoes that lose breathability as adhesives degrade.

- Cork Renewal: During resoling, fresh cork replenishes the moisture-wicking cavity, restoring the shoe’s "like-new" climate control.

Did you know? A well-maintained Goodyear welt shoe can outlast 5-7 cemented pairs while maintaining consistent breathability—making it a sustainable choice for bulk buyers like uniform suppliers.

Step Into Engineered Comfort

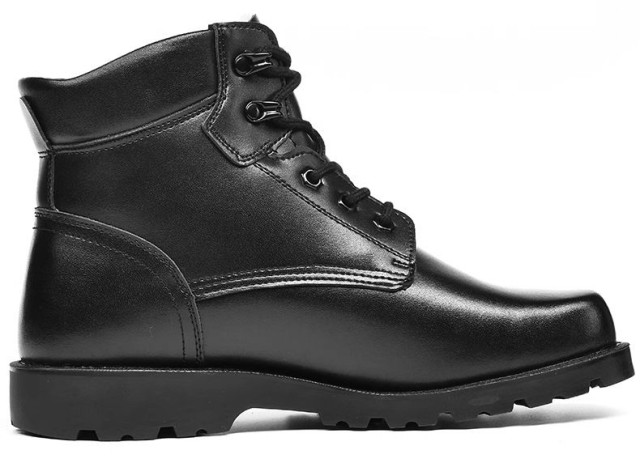

At 3515, we craft Goodyear welt footwear for distributors and brands who prioritize foot health in moisture-prone environments. Our construction delivers:

- Biomechanically Optimized Airflow through precision-stitched welts

- Natural Material Selection for active moisture management

- Decades-Long Performance via modular resole systems

Request our technical specifications to explore bulk solutions that keep wearers dry—from military contracts to hospitality uniforms.

Because when feet breathe easier, people move freely.

Related Products

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Classic Leather Derby Dress Shoes Wholesale & Custom Manufacturing

- Wholesale Durable Leather Work Boots | 8-Inch Goodyear Welt Manufacturer

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

Related Articles

- Why Vulcanized Shoes Dominate Durability and Comfort: A Technical and Practical Guide

- How Vulcanized Shoe Construction Delivers Unmatched Durability and Flexibility

- How Vulcanized Rubber Engineering Creates Unbeatable Outdoor Boots

- Optimizing Vamp Production for Vulcanized Shoes: Materials, Techniques, and Quality Assurance

- How Vulcanized Soles Became the Unsung Hero of Urban Footwear Culture