For footwear buyers prioritizing longevity and cost-efficiency, Goodyear welt construction remains the gold standard. This method’s triple-layer stitching, moisture-resistant design, and repairability outperform cemented soles and Blake stitching—translating to decades of wear with proper maintenance. Below, we dissect its engineering advantages and real-world performance.

The Anatomy of Goodyear Welt Construction

How Welt Stitching Creates a Structural Triad

Goodyear welts use a leather strip (welt) sewn to the shoe’s upper, insole rib, and outsole via a zigzag stitch. This forms a protective buffer zone that:

- Distributes impact forces across three layers instead of concentrating stress on direct sole attachments

- Prevents water seepage into the insole by creating a labyrinth-like barrier

- Enables clean sole replacements since the welt remains intact during resoling

Research shows this triad structure makes Goodyear-welted shoes 2–3 times more resistant to sole separation than Blake-stitched alternatives.

The Role of the Insole Rib in Load Distribution

A stiff leather or fiberboard rib glued to the insole serves as the stitching anchor. This rib:

- Reinforces arch support by maintaining midfoot rigidity

- Absorbs heel-strike shocks through its tension-resistant design

- Holds the cork filler that molds to the wearer’s foot over time

Unlike cemented constructions where soles detach under lateral pressure, the rib-welt bond preserves structural integrity even during heavy use.

Durability in Action: Use Cases and Longevity

Work Boots vs. Casual Footwear: Stress Test Comparisons

In industrial settings, Goodyear-welted work boots consistently outlast competitors:

| Scenario | Cemented Sole Lifespan | Goodyear Welt Lifespan |

|---|---|---|

| Warehouse shifts | 8–12 months | 3–5 years* |

| Construction work | 6–10 months | 2–4 years* |

*With annual sole replacements

The layered construction withstands abrasion from ladders, debris, and prolonged standing—failures common in cheaper boots.

How Repairability Extends Shoe Lifespan

A $100–$400 resoling every 2–3 years preserves the upper leather, which can last 10–15 years with care. Benefits include:

- Retaining custom foot molds from the cork bed

- Avoiding "new shoe" discomfort from rebreaking-in

- Reducing waste by replacing only worn soles

For dress shoes, this cuts long-term costs by 60% compared to replacing cemented pairs annually.

Why Alternatives Fall Short

Blake Stitching Limitations in Moisture Resistance

While sleeker, Blake stitching’s direct sole-upper attachment:

- Lacks waterproofing layers, allowing moisture to reach the insole faster

- Requires specialized cobblers for resoling due to internal stitching

- Wears out faster under heavy loads without welt reinforcement

Cemented Soles and Planned Obsolescence

Glued constructions dominate budget footwear but:

- Delaminate within months of exposure to heat/moisture

- Cannot be resoled—forcing full replacements

- Lose shape as adhesives degrade over time

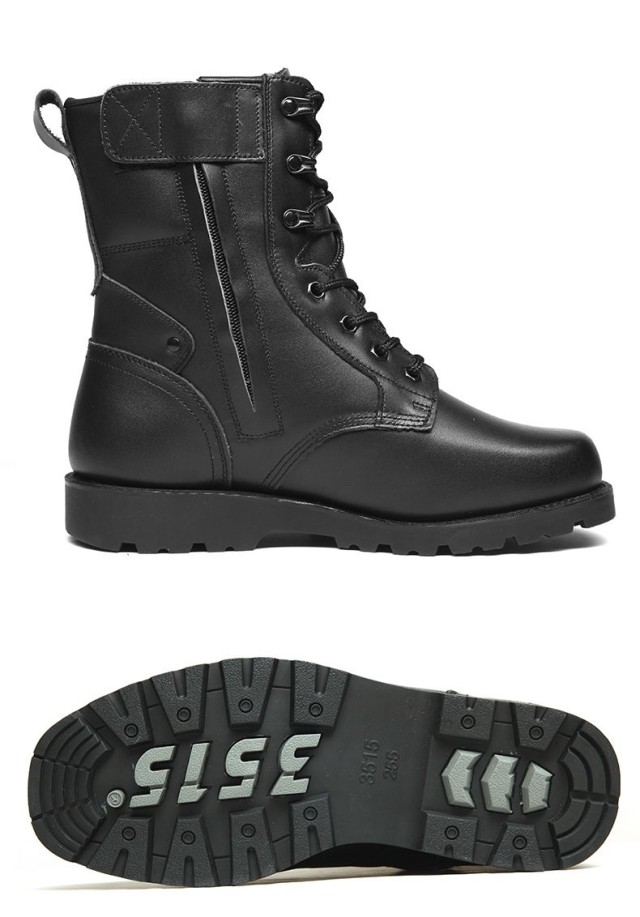

Upgrade Your Inventory with Future-Proof Footwear

3515 equips distributors and brands with Goodyear-welted footwear designed for decades of service. Our manufacturing expertise ensures every pair delivers the durability your customers demand—contact us to explore bulk solutions.

Related Products

- Wholesale Durable Camo Canvas Shoes with High-Traction Rubber Soles

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Athletic Safety Shoes with Dial Closure & Steel Toe for Wholesale & Custom Manufacturing

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

Related Articles

- How Vulcanized Rubber Boots Outperform Standard Footwear: Science and Practical Benefits

- How to Choose Tactical Footwear That Matches Your Public Safety Role

- How Tactical Footwear Shields Delivery Workers from Job-Specific Injuries

- How Tactical Footwear Technologies Ensure Mission-Critical Reliability

- How Tactical Footwear Camouflage Works: Science, Adaptation, and Mission Success