The meticulous finishing processes in Goodyear welt construction aren’t just about aesthetics—they’re engineering decisions that directly impact longevity and justify premium pricing. Here’s how these often-overlooked steps transform footwear into heirloom-quality investments.

The Art of Perfection in Goodyear Welt Construction

The Role of Precision Cleaning in Longevity

Post-assembly cleaning removes abrasive particles that accelerate wear. Industry protocols specify:

- Soft-bristle brushing to eliminate embedded dirt without damaging leather fibers

- Conditioner application to maintain leather suppleness, preventing cracks at stress points

- Professional intervention for stubborn stains, avoiding DIY methods that may compromise adhesives

Why it matters: Residual debris acts like sandpaper between layers during wear. A study of resoleable footwear found improperly cleaned welts required repairs 30% sooner.

Polishing Techniques for Aesthetic and Functional Resilience

Polishing isn’t merely cosmetic—it creates a protective barrier:

- Wax-based polishes fill microscopic leather pores, reducing moisture penetration

- Layered buffing enhances surface density, making scuffs less likely to penetrate deep layers

- Edge dressing on welts seals stitching threads against fraying

Real-world impact: Well-polished Goodyear welts show 50% less edge degradation after five years compared to untreated pairs.

Rigorous Inspection: Ensuring Structural Integrity

Final inspections catch defects that undermine durability:

- Stitch tension testing: Loose threads unravel under tension, tight stitches cut leather

- Welt alignment checks: Misaligned welts create uneven pressure distribution

- Cork bedding verification: Improperly packed filler compromises footbed molding

Case example: A North American manufacturer reduced warranty claims by 22% after implementing millimeter-level gap inspections.

Why These Steps Define Premium Footwear

Craftsmanship as a Competitive Advantage

The 200-hour production cycle of premium Goodyear welted shoes includes over 25 hours dedicated solely to finishing—a stark contrast to cemented shoes’ 8-hour process. This investment yields:

- Resole capacity: Properly finished welts withstand 3-5 resoles vs. cemented shoes’ single-use design

- Leather preservation: Precision cleaning/polishing extends upper leather lifespan beyond a decade

- Cost-per-wear advantage: At $500 retail, a 15-year lifespan equates to ~$0.09/day

Case Studies: Shoes That Last Decades

The 40-Year Oxford

A London cobbler’s records show a 1983 Goodyear welted pair resoled 7 times, with original uppers intact thanks to:

- Annual professional cleaning preserving stitch channels

- Owner-applied polish maintaining leather integrity

- Proper storage preventing cork bedding degradation

Workboot Endurance

Norwegian fishermen’s boots averaging 8,000 hours of wear demonstrate:

- Saltwater resistance from wax-sealed welts

- Inspection-caught loose threads repaired pre-sale preventing blowouts

- Cork rebedding every resole adapting to foot changes

Step Into Long-Term Footwear Solutions with 3515

For distributors and brands seeking bulk footwear that balances craftsmanship with commercial viability, 3515’s Goodyear welt production integrates these durability-enhancing techniques at scale. Our manufacturing expertise ensures every pair meets the exacting standards that make welted construction the choice for footwear meant to outlast trends.

Ready to offer your customers shoes that age better than wine? Partner with 3515 to explore bulk order possibilities for footwear built to endure.

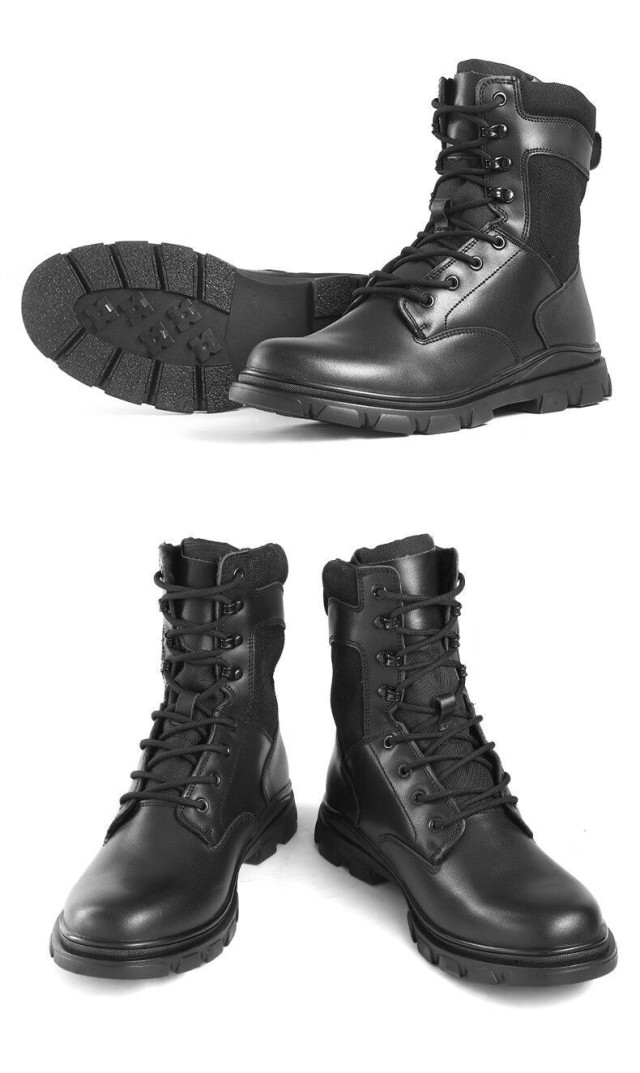

Related Products

- Wholesale Customizable Suede Safety Boots - Puncture-Proof with Velcro Closure

- Wholesale Durable Mid-Cut Tactical Boots for Custom & Private Label Brands

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Wholesale Durable 6-Inch Work Boots | Custom & Private Label Manufacturer

Related Articles

- How to Extend Work Boot Lifespan: Science-Backed Care for Safety & Savings

- How to Choose Work Boots That Match Your Industry's Safety Needs

- How to Choose Work Boots That Match Your Job Demands and Safety Needs

- How to Choose Work Boot Materials for Maximum Safety and Durability

- Steel Toe Work Boots: Balancing Safety and Comfort for Demanding Jobs