When selecting footwear, the outsole construction significantly impacts performance, durability, and comfort. Two dominant vulcanization methods—calendar and molded soles—offer distinct advantages depending on your needs. Whether you're a distributor sourcing bulk orders or a brand owner refining product lines, understanding these differences ensures optimal material choices.

Vulcanized Outsoles Demystified

Vulcanization transforms rubber into durable, flexible soles through heat and chemical processes. Both calendar and molded techniques create high-performance outsoles, but their manufacturing approaches yield different results.

How Calendar Soles Achieve Precision Tread Patterns

Calendar soles are produced by pressing pre-vulcanized rubber sheets through rollers (calenders) to create uniform thickness and intricate tread designs. This method excels in:

- Detailed patterning: Ideal for high-traction designs like herringbone or geometric grips.

- Consistency: Uniform rubber density enhances stability for casual and fashion-focused footwear.

- Cost efficiency: Lower tooling expenses suit small-batch production.

Did you know? Calendar soles dominate skateboarding shoes, where precise tread patterns prevent slippage during tricks.

The Durability Edge of Molded Soles

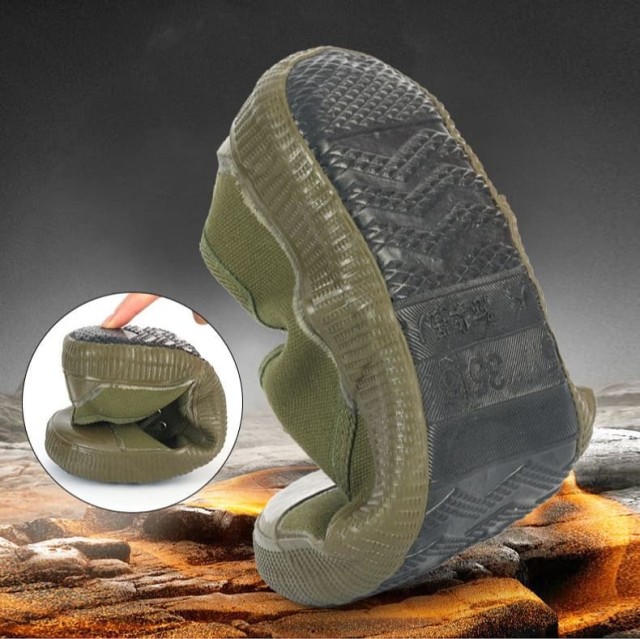

Molded soles involve injecting raw rubber into pre-shaped molds before vulcanization. Key benefits include:

- Enhanced abrasion resistance: Thicker rubber layers withstand heavy wear, ideal for work boots or hiking shoes.

- Seamless construction: Reduced delamination risk compared to layered calendar soles.

- Customizable density: Brands can adjust hardness for specific activities (e.g., softer soles for shock absorption).

Research shows molded outsoles last up to 30% longer in high-friction environments, making them a staple for industrial footwear.

Performance Breakdown: Traction, Weight, and Flexibility

Skate Shoes vs. Casual Sneakers: Industry Use Cases

- Skate shoes: Prioritize board feel and grip. Calendar soles’ thinner profile and precise treads offer superior flick control.

- Everyday sneakers: Molded soles provide all-day comfort with balanced cushioning and durability.

Why Leading Brands Mix Both Techniques

Hybrid designs leverage each method’s strengths:

- Multi-density soles: Molded bases with calendar-applied treads optimize grip and longevity.

- Targeted reinforcement: High-wear zones (toes/heels) use molded rubber, while calendar sheets cover midfoot areas for flexibility.

Optimize Your Footwear Line with 3515’s Expertise

Whether you need calendar soles for fashion-forward designs or molded soles for heavy-duty performance, 3515 delivers tailored vulcanization solutions. As a trusted manufacturer for distributors and brands, we ensure precision, scalability, and material excellence—helping you create footwear that meets market demands.

Ready to elevate your product range? Partner with 3515 to access cutting-edge sole technologies and bulk production capabilities.

Related Products

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Wholesale Durable Camo Canvas Shoes with High-Traction Rubber Soles

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Durable Canvas Work Shoes with Rubber Lug Sole | Wholesale Manufacturer

- Wholesale High-Traction Camo Boots - Custom Manufacturer for Brands

Related Articles

- How Vulcanized Rubber Boots Outperform Standard Footwear: Science and Practical Benefits

- How Vulcanized Rubber Work Boots Outlast Alternatives – And When to Choose Differently

- Optimizing Vamp Production for Vulcanized Shoes: Materials, Techniques, and Quality Assurance

- How Vulcanized Shoe Construction Delivers Unmatched Durability and Flexibility

- Vulcanized Shoes Decoded: When They Shine and When to Choose Alternatives