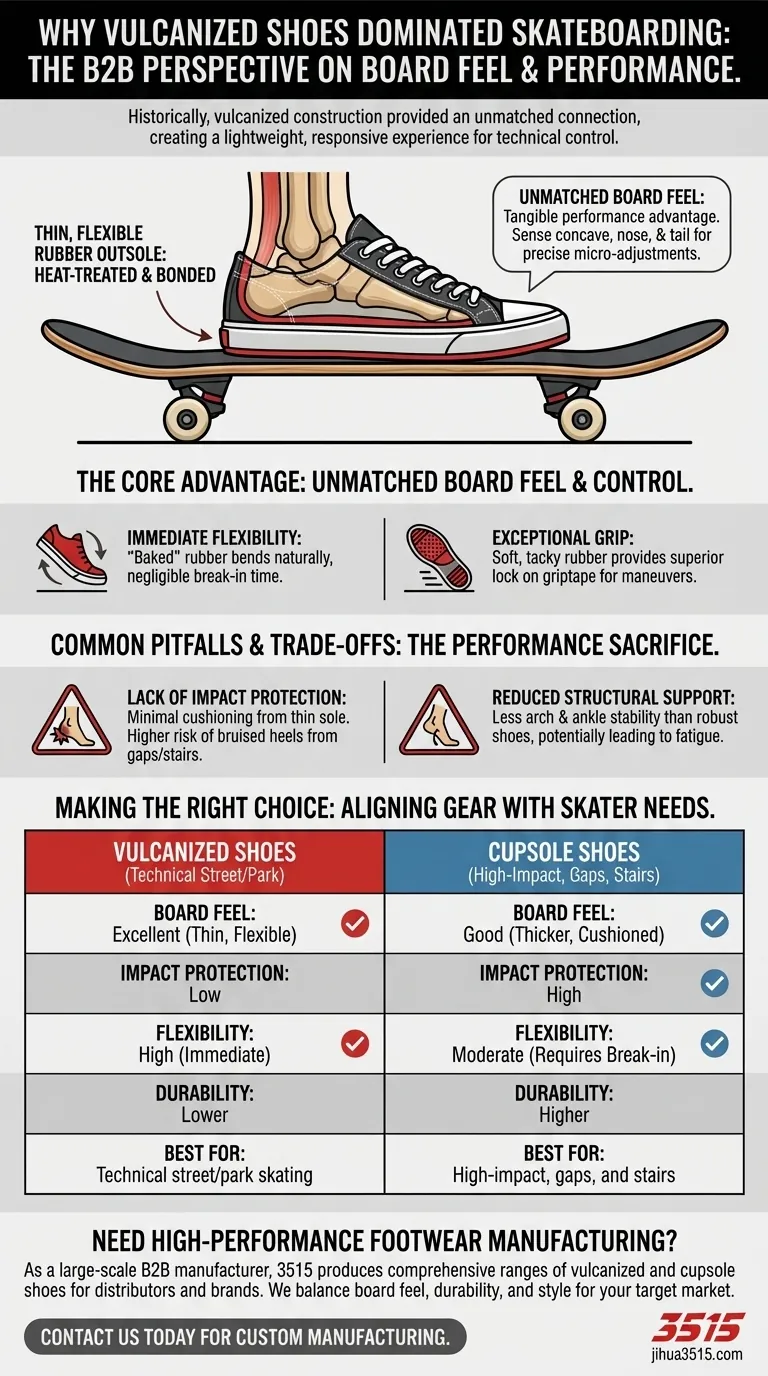

Historically, vulcanized shoes were the standard for skateboarding because their construction provides an unmatched connection between the skater's feet and the board. This "board feel" comes from a thin, flexible rubber outsole that is heat-treated to bond directly to the shoe's upper, creating a lightweight and responsive experience ideal for technical control.

The preference for vulcanized shoes boils down to a fundamental trade-off in skateboarding footwear: sacrificing impact protection and long-term durability for maximum board feel, flexibility, and grip.

The Core Advantage: Unmatched Board Feel

The primary reason skaters gravitated toward vulcanized shoes is a single, critical concept: board feel. This isn't just a marketing term; it's a tangible performance advantage.

What "Board Feel" Actually Means

Board feel is the skater's ability to sense the board's shape—its concave, nose, and tail—through the soles of their feet. This tactile feedback is crucial for making the micro-adjustments needed for flip tricks, grinds, and navigating transitions.

A shoe with good board feel acts as a thin intermediary, allowing the skater to manipulate the board with precision as if it were an extension of their own body.

How Vulcanization Creates This Sensation

The vulcanization process involves super-heating the rubber outsole until it cures and fuses with the shoe's canvas or suede upper. This creates a single, integrated unit.

The result is a significantly thinner and more flexible sole compared to other construction methods. It allows the shoe to bend naturally with the foot and the board, maximizing that critical sensory feedback.

Immediate Flexibility and Grip

A major benefit of this construction is that the shoes are skate-ready almost immediately. They require very little break-in time to achieve full flexibility.

Furthermore, the "baked" rubber is typically soft and tacky, providing the exceptional grip needed to stay locked onto the griptape during maneuvers.

Common Pitfalls and Trade-offs

While vulcanized shoes excel in feel and control, this specialized design comes with inherent disadvantages that every skater must consider.

The Downside of Thin Soles

The most significant trade-off is the lack of impact protection. The same thin sole that provides excellent board feel offers minimal cushioning.

Skaters landing tricks down stairs, gaps, or even on flat ground from a significant height will feel the impact much more acutely, leading to bruised heels and foot fatigue.

Reduced Structural Support

The simple, flexible construction of a vulcanized shoe generally offers less arch support and ankle stability than more robustly built shoes.

Over time, this can contribute to foot pain and may not be suitable for skaters who need additional support for pre-existing conditions or high-impact styles.

Making the Right Choice for Your Skating

The debate between vulcanized shoes and their more protective counterparts, cupsoles, is about aligning your gear with your specific needs. Neither is definitively "better"—they simply serve different purposes.

- If your primary focus is technical street or park skating: The superior board feel and flexibility of a vulcanized shoe provide the control necessary for flip tricks and precise maneuvers.

- If your primary focus is skating large gaps, stairs, or you need better foot protection: A cupsole shoe, with its thicker, cushioned sole, is the superior choice for absorbing impact and providing structural support.

Ultimately, choosing the right shoe means understanding what you are willing to sacrifice to gain a specific performance advantage.

Summary Table:

| Feature | Vulcanized Shoes | Cupsole Shoes |

|---|---|---|

| Board Feel | Excellent (Thin, flexible sole) | Good (Thicker, cushioned sole) |

| Impact Protection | Low | High |

| Flexibility | High (Immediate) | Moderate (Requires break-in) |

| Durability | Lower | Higher |

| Best For | Technical street/park skating | High-impact, gaps, and stairs |

Need High-Performance Skateboarding Footwear for Your Brand?

As a large-scale manufacturer, 3515 produces a comprehensive range of vulcanized and cupsole shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of performance footwear, ensuring the perfect balance of board feel, durability, and style for your target market.

Contact us today to discuss your custom manufacturing needs and elevate your product line.

Visual Guide

Related Products

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- What were traditional shoe soles made from before rubber? The History of Leather Soles

- What are some alternatives to hunting boots? Hiking, Rubber & Tactical Boots Explained

- What technical requirements are essential for outsoles in pivoting sports? Boost Grip and Lateral Stability

- What are the disadvantages of vulcanized soles? Lack of Support & Durability Explained

- How does tread affect outdoor footwear performance? Maximize Traction & Stability