At its core, resoling is easier with Goodyear welted shoes because of a dedicated component: the welt. This strip of leather acts as a middleman between the shoe's upper and the outsole. A cobbler can simply cut the stitches holding the sole to the welt and attach a new one without ever disturbing the fundamental structure of the shoe.

The Goodyear welt makes a shoe fundamentally repairable. It isolates the outsole so it can be replaced multiple times without compromising the integrity of the upper or the insole, dramatically extending the footwear's usable life.

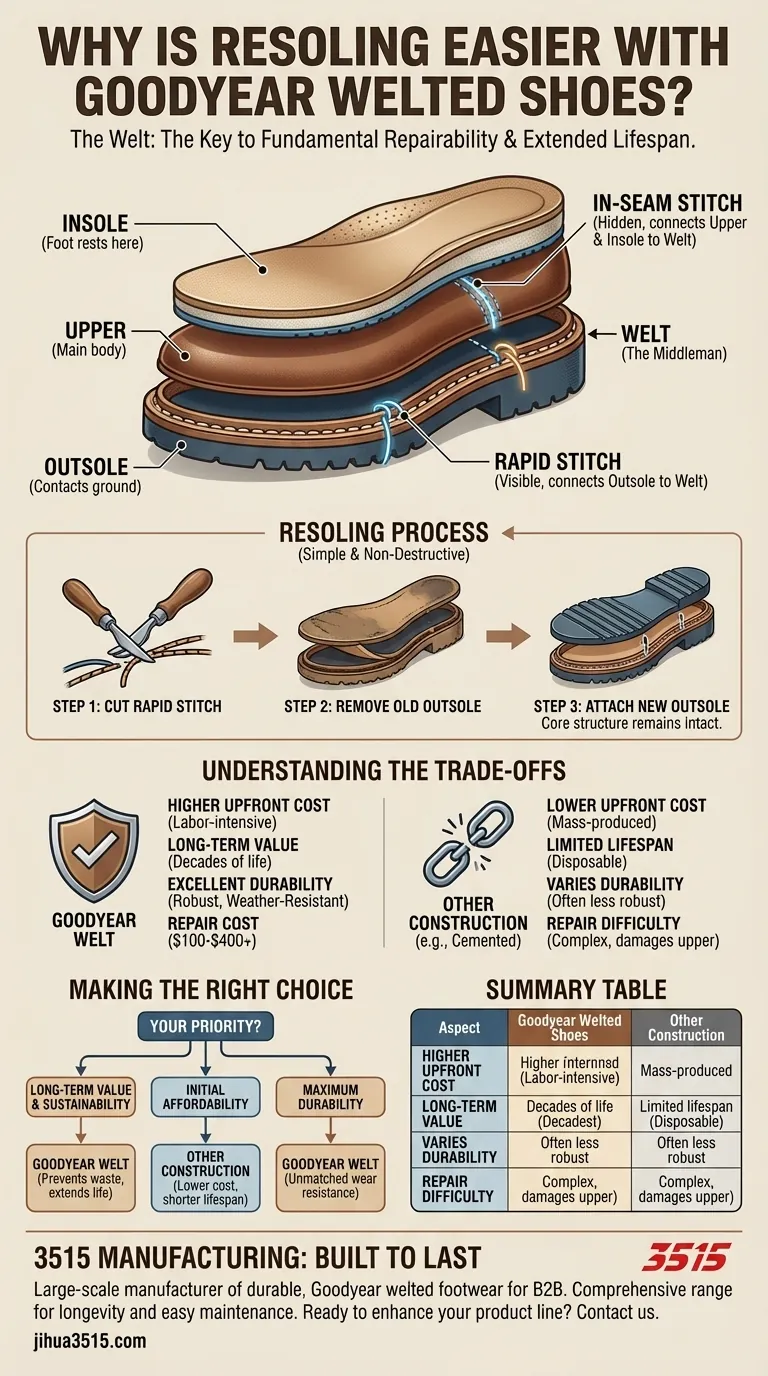

The Anatomy of a Resole-Friendly Shoe

To understand why the Goodyear welt is so effective, you must first understand its role in the shoe's construction. It’s a system designed for disassembly and reassembly from the very beginning.

The Key Components

A Goodyear welted shoe has four critical layers: the insole (what your foot rests on), the upper (the main leather body of the shoe), the welt (a strip of leather running along the outsole's edge), and the outsole (the part that contacts the ground).

The Two-Stitch System

This construction method relies on two independent stitches. The first, an in-seam stitch, sews the upper and the insole to the welt. This crucial stitch is hidden from view and is never touched during a resole.

The second stitch, called the rapid stitch, is what you see running along the outside edge of the sole. This stitch attaches the outsole to the welt.

Why This Design Is a Game-Changer

Because the outsole is only attached to the welt, a repair is straightforward. A cobbler simply cuts the rapid stitch, removes the old, worn-out sole, and then sews a new one directly onto the very same welt. The core of the shoe remains perfectly intact.

Understanding the Trade-offs

While prized for its longevity, the Goodyear welt construction involves a series of costs and benefits that are important to consider.

The Upfront Cost

Goodyear welting is a more labor-intensive and complex manufacturing process compared to mass-produced methods. This results in a higher initial purchase price.

The Cost of Repair

Resoling is not free. Depending on whether you use a local cobbler or send the shoes back to the original manufacturer, the service can range from around $100 to over $400.

The Benefit of Longevity

The primary benefit is that this repairability can significantly extend a shoe's lifespan. Instead of discarding a pair of shoes when the sole wears out, you can refresh them for a fraction of the cost of a new pair, making them a wise long-term investment.

Durability and Weather Resistance

The construction method also offers practical benefits beyond repair. The welt creates a more robust and water-resistant seal around the shoe, minimizing water penetration compared to simpler, glued-on soles.

Making the Right Choice for Your Goal

Deciding if a Goodyear welted shoe is right for you depends entirely on your priorities for your footwear.

- If your primary focus is long-term value and sustainability: The Goodyear welt is the superior choice, as its inherent repairability prevents waste and extends the life of the product for years, if not decades.

- If your primary focus is initial affordability: A different construction, such as a cemented sole, will have a lower upfront cost, but you must accept a much shorter, finite lifespan.

- If your primary focus is maximum durability: The robust, multi-layered construction of a Goodyear welt provides unmatched resistance to daily wear and tear.

Choosing a Goodyear welted shoe is an investment in a product that is built to be maintained, not replaced.

Summary Table:

| Aspect | Goodyear Welted Shoes | Other Construction (e.g., Cemented) |

|---|---|---|

| Resoling Process | Simple: Cut stitches to replace outsole without damaging the upper | Complex: Often requires damaging the upper, making repair difficult or impossible |

| Lifespan | Decades with proper care | Limited; typically discarded when sole wears out |

| Initial Cost | Higher due to labor-intensive construction | Lower upfront cost |

| Long-Term Value | High; cost per wear decreases over time | Low; disposable after sole wear |

| Durability & Weather Resistance | Excellent due to robust, sealed construction | Varies; generally less durable and water-resistant |

As a large-scale manufacturer, 3515 produces a comprehensive range of durable, Goodyear welted footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots designed for longevity and easy maintenance.

Ready to offer your customers footwear built to last? Contact us today to discuss how our reliable manufacturing can enhance your product line and provide exceptional value.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

People Also Ask

- What causes white marks on rubber boots, and how can they be removed? A Guide to 'Blooming' & Boot Care

- How do rubber soles affect a shoe's appearance? Defining Your Shoe's Style and Formality

- What are the advantages of rubber soles in sneakers? Unmatched Grip, Durability & Comfort

- Why might someone prefer rubber soles over leather soles? Unlock Durability & All-Weather Performance

- What material is commonly used for the soles of non-slip footwear and why? Unlock the Secrets of Safe Footwear