At its core, a Western work boot features one of three primary heel designs: the traditional tapered or "cowboy" heel, the underslung heel, and the modern block heel. The specific design and height are not merely stylistic; they are engineered for distinct functions, balancing the needs of horseback riding with the demands of groundwork.

The choice between a tapered, underslung, or block heel is a critical functional decision. It dictates the boot's performance, determining whether it prioritizes stirrup safety for riding or walking stability for all-day work on your feet.

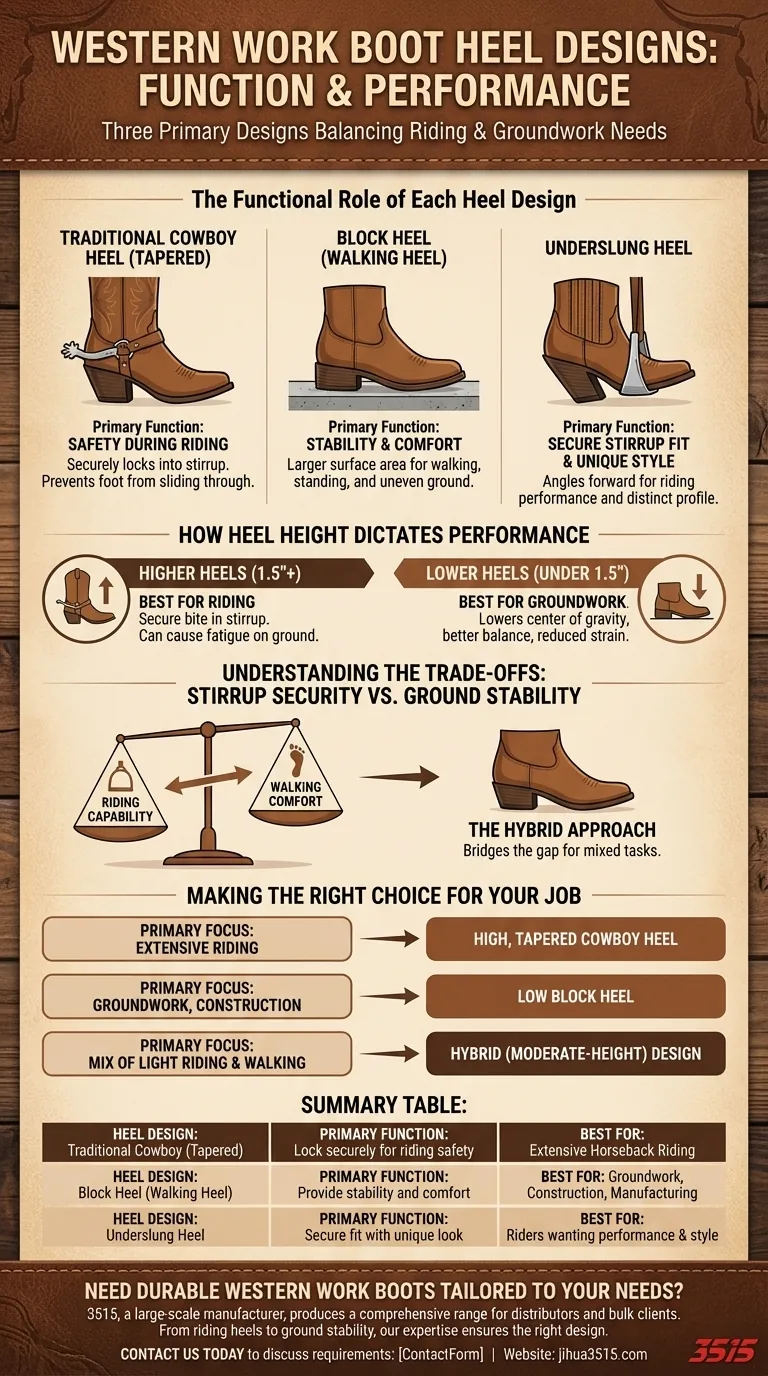

The Functional Role of Each Heel Design

Western boots are iconic, but in a work context, every design element serves a purpose. The heel is arguably the most critical component for safety and performance, directly influencing how you interact with your environment.

The Traditional Cowboy Heel (Tapered)

The classic cowboy heel is defined by its height (typically 1.5 inches or more) and its distinct, angled or "tapered" shape.

Its primary function is safety during horseback riding. The slanted profile allows the heel to lock securely into a stirrup, preventing the foot from sliding too far forward and getting caught in a fall.

The Block Heel (Walking Heel)

The block heel is the most significant adaptation for the modern work environment. It is shorter, wider, and has a flat bottom, closely resembling the heel on a traditional work boot.

This design provides a much larger surface area, which dramatically increases stability and comfort for walking, standing, or working on hard or uneven ground.

The Underslung Heel

The underslung heel is a stylistic variation where the back of the heel stack angles forward more sharply than the front.

While it creates a distinct profile, it functions similarly to a traditional cowboy heel. The aggressive angle helps secure the boot in a stirrup, making it a popular choice for those who want both riding performance and a unique look.

How Heel Height Dictates Performance

Beyond the shape, the height of the heel is a crucial factor that separates a riding boot from a true work boot.

Higher Heels (1.5"+)

Taller heels are purpose-built for riders. They offer the most secure "bite" into the stirrup, promoting proper posture and control in the saddle.

However, this height can cause instability and foot fatigue when walking for extended periods, especially on concrete or rough terrain.

Lower Heels (Under 1.5")

A lower heel is the definitive feature of a Western boot designed for groundwork. Often paired with a block shape, this design lowers your center of gravity.

This results in superior balance and reduces strain on your arches and lower back, making it the practical choice for anyone spending more time on their feet than in the saddle.

Understanding the Trade-offs

Choosing a Western work boot involves balancing tradition with modern functional requirements. The primary trade-off is between riding capability and walking comfort.

Stirrup Security vs. Ground Stability

A high, tapered heel is excellent for keeping your foot in a stirrup but offers a small, less stable contact point with the ground. A low, block heel provides a solid, stable foundation for walking but offers minimal security in a stirrup.

The Hybrid Approach

Many modern Western work boots attempt to bridge this gap. They often feature a heel that is lower than a traditional riding heel but still has a slight taper, offering a compromise for individuals who do a mix of riding and groundwork.

Making the Right Choice for Your Job

Your daily tasks should be the deciding factor in selecting a heel design.

- If your primary focus is extensive horseback riding: A traditional high, tapered cowboy heel is essential for safety and control in the stirrup.

- If your primary focus is groundwork, construction, or manufacturing: A low block heel is the non-negotiable choice for all-day stability and comfort.

- If your work involves a mix of light riding and walking: Look for a hybrid design with a moderate-height block or slightly tapered heel to balance both needs.

Ultimately, selecting the right heel transforms the boot from a piece of classic apparel into an essential tool for your work.

Summary Table:

| Heel Design | Primary Function | Best For |

|---|---|---|

| Traditional Cowboy Heel (Tapered) | Lock securely into stirrups for riding safety | Extensive horseback riding |

| Block Heel (Walking Heel) | Provide stability and comfort for walking/standing | Groundwork, construction, manufacturing |

| Underslung Heel | Secure boot in stirrup with a unique look | Riders wanting performance and style |

Need Durable Western Work Boots Tailored to Your Needs?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Whether you need boots with traditional riding heels for equestrian safety or modern block heels for all-day ground stability, we have the production capabilities to meet your demands. Our expertise ensures you get the right heel design for maximum performance and comfort.

Contact us today to discuss your Western work boot requirements and benefit from our extensive manufacturing experience!

Visual Guide

Related Products

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What material is recommended for harness boots? Choose the Right Protection for Your Work

- What are the different types of cowboy boots? Choose the Right Boot for Riding, Work, or Style

- What are the key advantages of cowboy boots? Discover Unmatched Durability & Style

- Which type of boot offers better fit retention over time? The Answer Lies in Adjustable Design

- What are the main safety features of mining boots? Essential Protection for Harsh Environments

- How should work boots be maintained to prolong their lifespan? Essential Care for Long-Lasting Safety

- What are the drawbacks of pull-on work boots? A Guide to Fit, Support, and Safety

- How should women's work boots be cared for and maintained? Extend Boot Life & Protect Your Feet