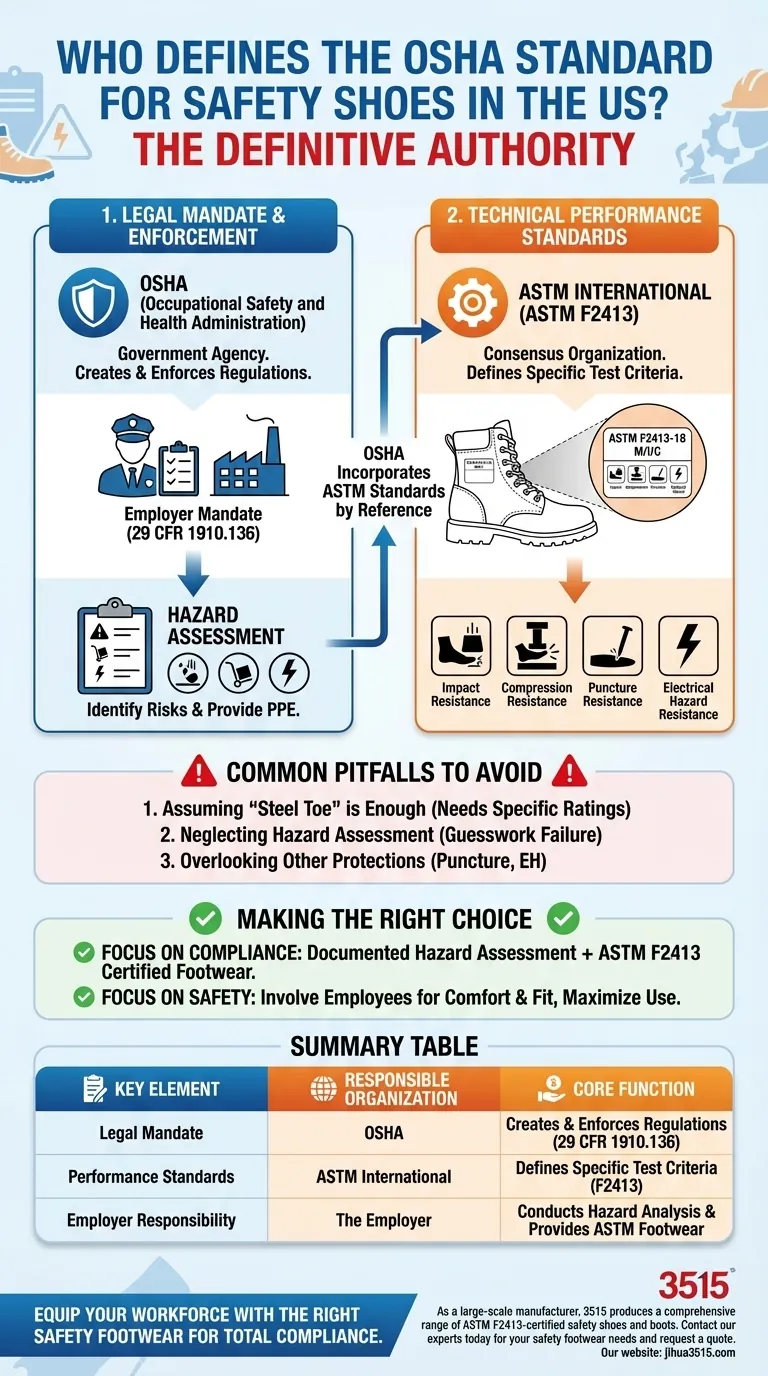

The definitive authority on workplace safety shoe standards in the United States is OSHA itself. The Occupational Safety and Health Administration (OSHA) is the government agency that creates and enforces the regulations. These standards are not suggestions; they are legal requirements designed to ensure employers protect their workers from preventable foot injuries in hazardous environments.

While OSHA sets the legal mandate for when protective footwear is required, it relies on technical consensus standards from organizations like ASTM International to define the specific performance criteria for the shoes. Understanding this two-part system is the key to ensuring both compliance and genuine safety.

The Role of OSHA in Workplace Foot Protection

OSHA’s primary goal is to ensure safe and healthful working conditions. For foot protection, their approach is to define the employer's responsibility and the types of hazards that must be addressed, rather than designing the footwear itself.

The Employer's Mandate

The core of the regulation, found in 29 CFR 1910.136, states that employers must require employees to use protective footwear when they are working in areas with a danger of foot injuries.

This places the legal responsibility squarely on the employer to assess the workplace, identify risks, and provide the appropriate personal protective equipment (PPE).

Identifying Core Hazards

OSHA's standard is concerned with protecting workers from a specific set of common industrial hazards.

These include injuries from falling or rolling objects (impact and compression), objects piercing the sole of the shoe (puncture), and exposure to electrical circuits (electrical hazards).

Enforcement and Inspection

OSHA ensures these standards are met through workplace inspections. A compliance officer will verify that the employer has conducted a proper hazard assessment and that the employees are using footwear appropriate for the identified risks.

How Technical Standards Complete the Picture

OSHA tells you that you need protection, but it looks to other expert organizations to define how well that protection must perform. This is where consensus standards become critical.

The Link to ASTM International

For safety footwear, the most important standard is ASTM F2413. OSHA's regulations incorporate this standard by reference.

This means that for a safety shoe to be considered compliant with OSHA's mandate, it must first meet the performance criteria outlined in the relevant ASTM standard.

What ASTM Standards Define

The ASTM standard provides the specific testing and performance requirements for safety footwear.

It defines precise criteria for things like impact resistance (I), compression resistance (C), metatarsal protection (Mt), and electrical hazard (EH) resistance.

Reading the Label on Your Boot

Proof of compliance is found on a label inside the shoe. This label will state that it conforms to ASTM F2413 and list the specific protections it offers (e.g., "ASTM F2413-18 M/I/C"). This code is the language of compliance.

Common Pitfalls to Avoid

Simply providing any "steel-toe" boot is a common and dangerous mistake. True compliance requires a more thoughtful approach to avoid these frequent oversights.

Assuming "Steel Toe" Is Enough

The term "steel toe" is generic. The critical factor is whether the shoe meets the specific ASTM impact and compression ratings required for the hazards present in your specific workplace.

Neglecting the Hazard Assessment

The most common failure is not performing or documenting a proper job hazard analysis (JHA). Without a formal assessment of the specific risks (e.g., 50-pound objects falling from 3 feet vs. a rolling 2-ton cart), selecting the right footwear becomes guesswork.

Overlooking Other Protections

Many jobs require more than just impact protection. Hazards like sharp objects on the ground (requiring a puncture-resistant plate) or live electrical circuits (EH rating) are often overlooked if the focus is solely on falling objects.

Making the Right Choice for Your Goal

Your approach to safety footwear should be guided by your ultimate objective, whether it's strict legal compliance or creating the safest possible work environment.

- If your primary focus is legal compliance: Ensure your program is based on a documented hazard assessment and that all selected footwear is certified to the ASTM F2413 standard.

- If your primary focus is maximizing worker safety: Involve employees in the selection process to evaluate comfort and fit, as this dramatically increases the likelihood of consistent and correct use.

- If you are an employee: Check for the ASTM F2413 label inside your boot and confirm with your supervisor that its specific protections match your job's hazards.

A truly effective safety footwear program is built on a clear understanding of workplace risks, not just on the procurement of equipment.

Summary Table:

| Key Element | Responsible Organization | Core Function |

|---|---|---|

| Legal Mandate | OSHA (Occupational Safety and Health Administration) | Creates and enforces regulations (29 CFR 1910.136) requiring protective footwear. |

| Performance Standards | ASTM International (ASTM F2413) | Defines specific test criteria for impact, compression, puncture, and electrical hazard resistance. |

| Employer Responsibility | The Employer | Must conduct a job hazard analysis and provide ASTM-certified footwear matching the identified risks. |

Ensure your workforce is equipped with the right safety footwear for total compliance and protection.

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM F2413-certified safety shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear designed to meet the specific hazards identified in your workplace hazard assessment.

We help you protect your team and simplify compliance. Contact our experts today to discuss your safety footwear needs and request a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

People Also Ask

- Can heavy duty work boots be worn daily outside of work? Discover Durable, All-Day Comfort

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- Are employers required to provide steel-toe rubber boots at no cost to employees? Yes, under OSHA rules.