Textiles are a foundational material in modern footwear because their versatility stems from a nearly infinite combination of fibers, weaves, colors, and specialized treatments. This allows designers to create everything from classic, durable waxed canvas to lightweight, high-tech 3D air mesh, providing an unmatched palette for both aesthetic expression and functional performance.

True textile versatility in footwear isn't just about color or pattern; it's about the technical control designers have over a fabric's core properties. By manipulating key elements—from fiber type to surface finish—a single material can be precisely engineered for durability, breathability, or flexibility.

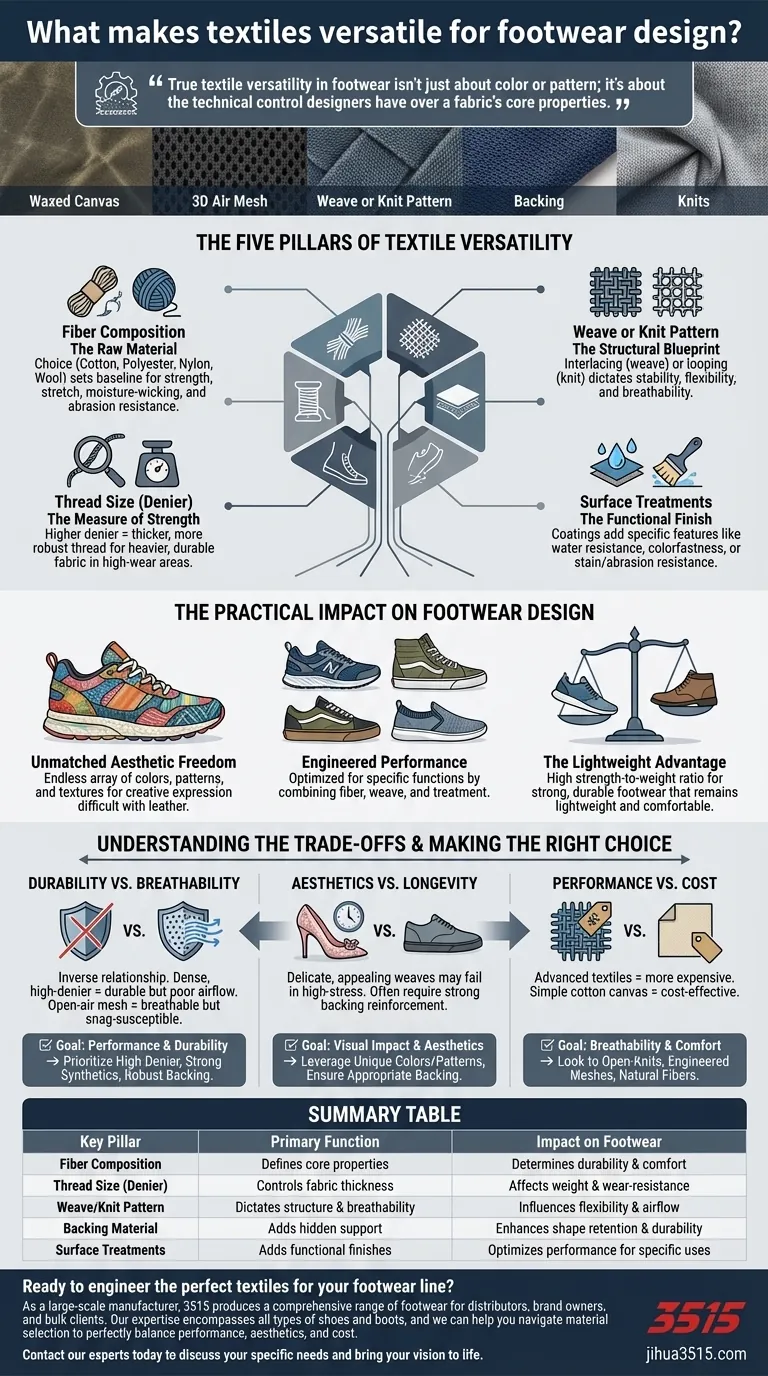

The Five Pillars of Textile Versatility

The adaptability of any textile is not accidental. It is the direct result of five controllable factors that determine its final look, feel, and performance in a shoe.

Fiber Composition: The Raw Material

The type of fiber used—such as cotton, polyester, nylon, or wool—establishes the baseline properties of the fabric. This choice dictates inherent characteristics like strength, stretch, moisture-wicking capabilities, and abrasion resistance.

Thread Size (Denier): The Measure of Strength

Denier is the unit of measurement for thread weight and thickness. A higher denier indicates a thicker, more robust thread, resulting in a heavier and more durable fabric ideal for high-wear areas.

Weave or Knit Pattern: The Structural Blueprint

How threads are interlaced (weave) or looped (knit) fundamentally changes the fabric's behavior. A tight plain weave creates a stable, durable canvas, while an open knit structure provides flexibility and exceptional breathability.

Backing Material: The Hidden Support

Many textiles used in footwear are fused with a backing material. This hidden layer adds structure, prevents unwanted stretching during manufacturing and wear, and enhances overall durability without compromising the surface appearance.

Surface Treatments: The Functional Finish

Finally, surface treatments and coatings can add specific performance features. Applying wax creates water resistance, while other finishes can improve colorfastness to prevent fading or increase resistance to stains and abrasion.

The Practical Impact on Footwear Design

Understanding these five pillars allows designers to move beyond simply choosing a fabric and instead specify a material engineered for a precise purpose.

Unmatched Aesthetic Freedom

The most visible form of versatility is the endless array of colors, patterns, and textures available. Textiles allow for creative expression that is difficult to achieve with materials like leather.

Engineered Performance

By combining the right fiber, weave, and treatment, a textile can be optimized for a specific function. This results in breathable air mesh for running shoes, rugged canvas for skate shoes, or flexible knits for casual wear.

The Lightweight Advantage

One of the most significant benefits of textiles is their high strength-to-weight ratio. This enables the creation of strong, durable footwear that remains lightweight and comfortable for the wearer.

Understanding the Trade-offs

Material selection is a critical process, as choosing the wrong textile can undermine the entire shoe. An informed decision requires balancing competing priorities.

Durability vs. Breathability

There is often an inverse relationship between these two properties. A dense, high-denier weave will be extremely durable but offer poor airflow, while an open-air mesh will be highly breathable but more susceptible to snags and abrasion.

Aesthetics vs. Longevity

A visually appealing, delicate weave might be perfect for a fashion statement but will fail quickly in a high-stress area. Its use often requires reinforcement with a strong backing, which can alter the fabric's drape and feel.

Performance vs. Manufacturing Cost

Advanced textiles with special fibers, complex knits, and performance coatings are significantly more expensive to produce. A simple cotton canvas is far more cost-effective than a custom-engineered, multi-layer technical fabric.

Making the Right Choice for Your Goal

Your primary objective for the shoe should dictate your material specifications. By focusing on the end goal, you can navigate the trade-offs effectively.

- If your primary focus is performance and durability: Prioritize high-denier threads, strong synthetic fibers like nylon, and robust backing materials to ensure the shoe withstands intense wear.

- If your primary focus is breathability and comfort: Look to open-knit structures, engineered meshes, and natural fibers known for moisture management.

- If your primary focus is visual impact and aesthetics: Leverage unique colors and intricate patterns, but ensure you pair them with the appropriate backing to provide necessary structural integrity.

By understanding these core components, you can move beyond simple selection and begin to engineer the perfect textile for any footwear vision.

Summary Table:

| Key Pillar | Primary Function | Impact on Footwear |

|---|---|---|

| Fiber Composition | Defines core properties (strength, stretch, moisture-wicking) | Determines durability and comfort |

| Thread Size (Denier) | Controls fabric thickness and robustness | Affects weight and wear-resistance |

| Weave/Knit Pattern | Dictates structure, stability, and breathability | Influences flexibility and airflow |

| Backing Material | Adds hidden support and prevents stretching | Enhances shape retention and durability |

| Surface Treatments | Adds functional finishes (water resistance, etc.) | Optimizes performance for specific uses |

Ready to engineer the perfect textiles for your footwear line?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our expertise encompasses all types of shoes and boots, and we can help you navigate material selection to perfectly balance performance, aesthetics, and cost.

Contact our experts today to discuss your specific needs and bring your vision to life.

Visual Guide

Related Products

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What is the relationship between footwear design and the effectiveness of biomechanical alignment? Maximize Stability

- How can high-quality tactical or athletic footwear mitigate social participation restrictions? Enhance Your Mobility

- How do specialized training shoes and sneakers support high-intensity training? Maximize Performance & Stability

- How do professional athletic shoes contribute to safety on flexible balance boards? Enhance Stability & Prevent Slips

- How do safety harnesses assist in high-intensity treadmill testing? Ensure Data Validity for High-Performance Footwear