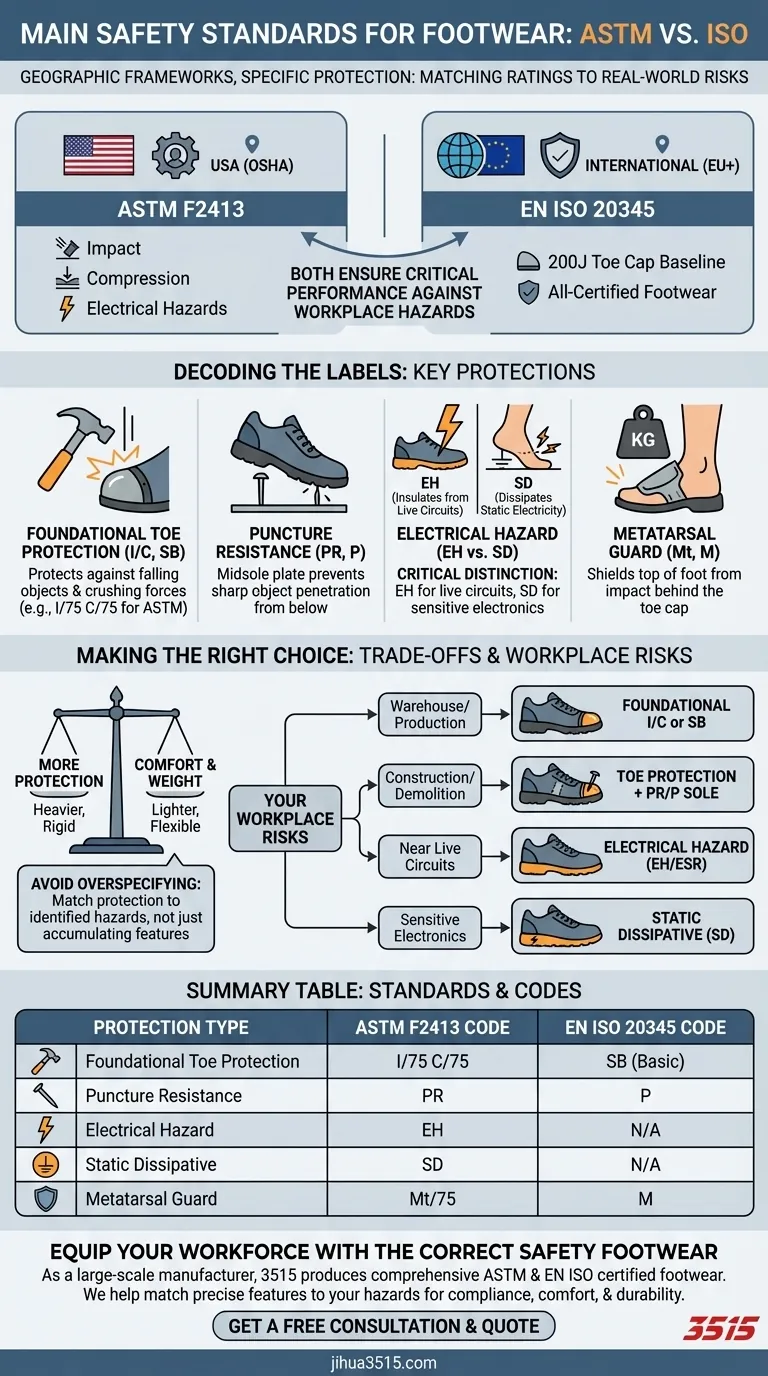

The primary safety standards for protective footwear are not universal; they are dictated by geography. In the United States, the governing standard is ASTM F2413, which is legally mandated by OSHA. For Europe and many other international regions, the key standard is EN ISO 20345. Both standards ensure footwear meets critical performance requirements for protecting against workplace hazards.

While knowing the names of the standards is the first step, the crucial task is understanding that these standards are frameworks. Your actual safety depends on matching the specific protection ratings within a standard to the real-world risks of your job.

The Two Pillars of Safety Footwear Standards

To select the right footwear, you must first understand which regulatory framework applies to your workplace. The two most dominant standards create a clear geographical and regulatory dividing line.

The U.S. Standard: ASTM F2413

In the United States, the Occupational Safety and Health Administration (OSHA) requires that employers ensure personnel wear appropriate protective footwear.

OSHA's regulations (specifically 29 CFR 1910.136) mandate that this footwear must comply with the standards set by the American Society for Testing and Materials (ASTM). The current version is ASTM F2413.

This standard establishes minimum requirements for the performance and testing of footwear to protect against a variety of workplace dangers, including impact, compression, and electrical hazards.

The International Standard: EN ISO 20345

Outside of the U.S., particularly in Europe, the most prevalent standard is EN ISO 20345. This is the benchmark against which all "safety footwear" is tested and certified.

The core, non-negotiable requirement of this standard is front foot protection. The toe cap must be able to withstand a 200-joule impact before it fractures, providing a baseline level of safety for all certified footwear.

Decoding the Labels: What Protections Really Mean

A boot's compliance with a standard is only the beginning. The specific codes on the label tell you what hazards it is designed to handle. A thorough risk assessment of your environment is necessary to choose the right features.

Foundational Toe Protection (Impact & Compression)

This is the most fundamental feature of any safety shoe. It protects the toes from falling objects and crushing forces.

Under ASTM F2413, this is often indicated by a rating like I/75 C/75, which signifies the highest level of protection against 75 foot-pounds of impact and 2,500 pounds of compression.

Protection from Below (Puncture Resistance)

For environments like construction sites where sharp objects like nails are a constant threat, a puncture-resistant sole is critical.

A special plate, often made of steel or a composite material, is embedded in the midsole to prevent sharp objects from penetrating the bottom of the foot.

Electrical Hazard Protection (EH vs. SD)

This is a frequently misunderstood area where choosing the wrong boot can be dangerous.

Electrical Hazard (EH or ESR) footwear is designed with non-conductive, shock-resistant soles and heels. It protects the wearer from accidental contact with live electrical circuits.

Static Dissipative (SD) footwear does the opposite. It is designed to reduce the buildup of static electricity, protecting sensitive electronic equipment from damage. It does not offer protection from live circuits.

Specialized Protections (Metatarsal)

For industrial work with a high risk of heavy objects falling onto the foot, additional protection may be required.

Metatarsal (M) guards provide a shield over the top of the foot (the metatarsal bones) to protect against impacts that could occur behind the main safety toe cap.

Understanding the Trade-offs

Choosing safety footwear isn't just about accumulating the most features. Each protective element comes with considerations that affect comfort, cost, and suitability for a given task.

Protection vs. Comfort and Weight

As a general rule, more protective features mean a heavier and more rigid boot. A steel plate for puncture resistance and an external metatarsal guard will significantly increase weight and reduce flexibility compared to a basic composite-toe shoe.

Overspecifying Your Footwear

Buying a boot with every possible rating is not always the best strategy. Using an EH-rated boot in an environment where static dissipation is needed can put expensive equipment at risk. The goal is to match the protection to the specific, identified hazards.

Durability and Environment

The materials of the boot matter. A leather upper, while durable, may not be suitable for constantly wet environments. Slip-resistant and oil-resistant soles are critical in some areas but may be less important in others. The longevity of the footwear depends on choosing materials suited to the daily working conditions.

Making the Right Choice for Your Environment

Your final decision should be guided by a clear understanding of your workplace risks.

- If your primary focus is general handling, warehouse, or production work: Ensure your footwear meets the foundational ASTM or ISO standard for impact and compression resistance on the toe cap.

- If your primary focus is construction, demolition, or waste management: Prioritize footwear with both toe protection and a certified puncture-resistant sole plate.

- If your primary focus is working near live electrical circuits: You must select footwear with a specific Electrical Hazard (EH or ESR) rating to insulate you from the ground.

- If your primary focus is protecting sensitive electronics (e.g., automotive or computer industries): Choose Static Dissipative (SD) footwear to prevent static buildup and discharge.

Ultimately, the best safety footwear is the one correctly specified for the hazards you face every day.

Summary Table:

| Protection Type | ASTM F2413 Code | EN ISO 20345 Code | Key Feature |

|---|---|---|---|

| Foundational Toe Protection | I/75 C/75 | SB (Basic) | Protects against impact and compression |

| Puncture Resistance | PR | P | Midsole plate prevents sharp object penetration |

| Electrical Hazard | EH | Not Applicable | Insulates from live circuits |

| Static Dissipative | SD | Not Applicable | Reduces static electricity buildup |

| Metatarsal Guard | Mt/75 | M | Protects the top of the foot from impacts |

Ensure your workforce is equipped with the correct safety footwear.

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM and EN ISO certified footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, from basic toe protection to specialized models with EH, SD, PR, and Metatarsal ratings.

We help you match the precise protective features to your specific workplace hazards, ensuring compliance, comfort, and durability. Contact our experts today to discuss your requirements and receive a customized solution.

Get a Free Consultation & Quote

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Metatarsal Guard Safety Boots Work Shoes

People Also Ask

- How do 3D scanning and additive manufacturing transform protective equipment? Experience 100% Anatomical Customization

- How does EN ISO 20347 differ from EN ISO 20345? Choose the Right Safety Footwear for Your Workplace

- Why are composite-toe boots suitable for composite manufacturing? The Ideal Safety Solution

- What is the function of an industrial sling crane in safety shoe raw material handling? Optimize Your Production Line

- What is the purpose of the lining in safety shoes? Achieve Superior Foot Comfort & Health

- How do optical motion capture systems and skin markers function in safety footwear walking experiments? Boost Gait Accuracy

- Why are industrial safety shoes classified as high-priority inventory? Maximize Your Distribution Strategy Efficiency

- What are some specialized features available in modern safety shoes beyond toe protection? Enhanced Workplace Safety