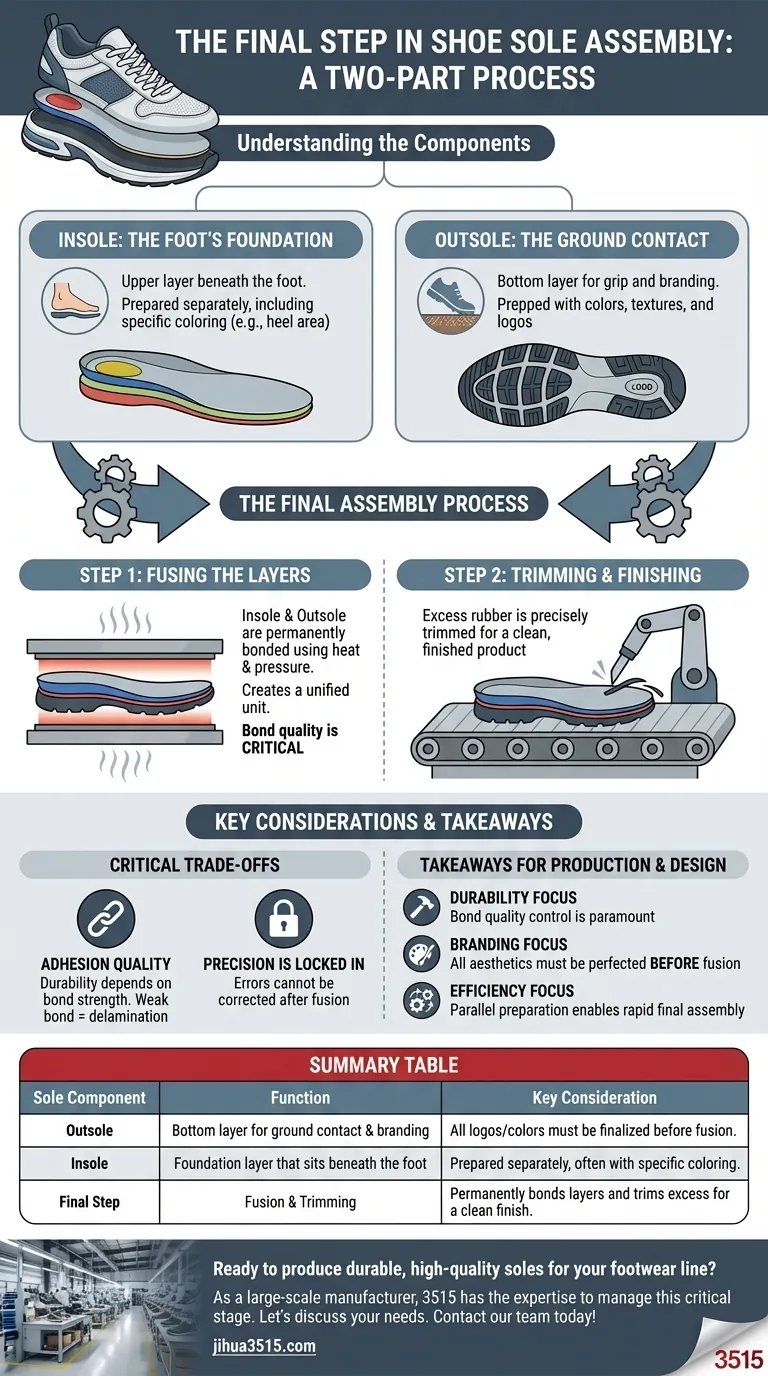

The final step in creating a complete shoe sole is a two-part assembly process. First, the two primary components—the prepared insole and the outsole—are permanently fused together. Second, any excess rubber is trimmed from the edges to create a clean, finished product ready for the shoe's upper.

The creation of a modern shoe sole is not about molding a single piece of material. It is an assembly process where two distinct components are prepared in parallel and then permanently bonded in a final, critical step.

The Two Core Components of a Sole

Before the final step can occur, two separate parts of the sole must be manufactured. Understanding these components is key to understanding the final assembly.

The Outsole: The Point of Contact

The outsole is the bottom-most layer of the shoe that makes direct contact with the ground.

This component is prepped with the necessary colors and textures. It's where you will find primary branding, logos, and the main background color of the sole.

The Insole: The Foundation for the Foot

The insole is the upper part of the sole unit that will eventually sit just beneath the wearer's foot.

This piece also requires its own preparation, often involving specific coloring for elements like the heel area before it's ready for assembly.

Why Use Separate Components?

Manufacturing the sole in two parts allows for greater complexity and customization. It enables manufacturers to use different materials or colors for branding on the outsole while preparing the insole for its role, which are then combined for the best of both worlds.

The Final Assembly Process

Once both the insole and outsole are fully prepared, they come together in the final manufacturing stage.

Step 1: Fusing the Layers

The primary action is fusion. The prepared insole and outsole are aligned and then permanently bonded together, typically using heat and pressure.

This creates a single, unified sole unit from the two previously separate components. The bond must be incredibly strong to withstand the stresses of walking and running.

Step 2: Trimming and Finishing

After fusion, there is often excess rubber or bonding material around the edges of the newly formed sole.

This excess is carefully trimmed away to create a precise shape and a clean, aesthetically pleasing finish. The sole is now complete.

Understanding the Trade-offs

This assembly method is efficient but carries critical points of consideration that determine the final quality of the shoe.

Adhesion Quality is Paramount

The entire durability of the sole depends on the quality of the fusion bond. A weak or incomplete bond will lead to delamination, where the outsole peels away from the rest of the shoe—a common point of failure.

Precision is Locked In

Any errors in the preparation of the individual components, such as a misprinted logo on the outsole, cannot be corrected after the fusion step. The process is final.

Key Takeaways for Production and Design

Apply this understanding to your specific goals.

- If your primary focus is durability: The quality control for the fusion process is the most critical factor, as this bond determines the sole's lifespan.

- If your primary focus is branding: All aesthetic work on logos and colors must be perfected on the individual outsole and insole components before they are fused.

- If your primary focus is manufacturing efficiency: The process is an assembly line where parallel preparation of insoles and outsoles converges for a final, rapid fusion and trimming stage.

Understanding this final assembly stage is key to appreciating the engineering behind a high-quality and long-lasting shoe sole.

Summary Table:

| Sole Component | Function | Key Consideration |

|---|---|---|

| Outsole | Bottom layer for ground contact & branding | All logos/colors must be finalized before fusion. |

| Insole | Foundation layer that sits beneath the foot | Prepared separately, often with specific coloring. |

| Final Step | Fusion & Trimming | Permanently bonds layers and trims excess for a clean finish. |

Ready to produce durable, high-quality soles for your footwear line?

As a large-scale manufacturer, 3515 has the expertise and production capabilities to expertly manage the critical final assembly stage. We ensure a strong, permanent bond between the insole and outsole, guaranteeing the durability and finish your brand demands.

We produce a comprehensive range of footwear for distributors, brand owners, and bulk clients. Let's discuss your sole production needs. Contact our team today to get started!

Visual Guide

Related Products

- Premium Safety Shoes with Rotating Buckle Safety Sneakers

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Comfort Leather Business Shoes with Dial Lacing System

People Also Ask

- What is the difference between shoe size and fit? Master the 3D Shape for Perfect Comfort

- What are the key considerations for finding a perfect fitting safety toe boot? Avoid Injury and Discomfort

- What is the most common shoe width for safety toe boots? The Critical Fit Guide for Comfort & Safety

- Are safety shoes worth it? The Critical Investment in Workplace Safety & Foot Health

- Are safety toe options available for women's work boots? A Guide to Steel, Composite & Alloy Toes