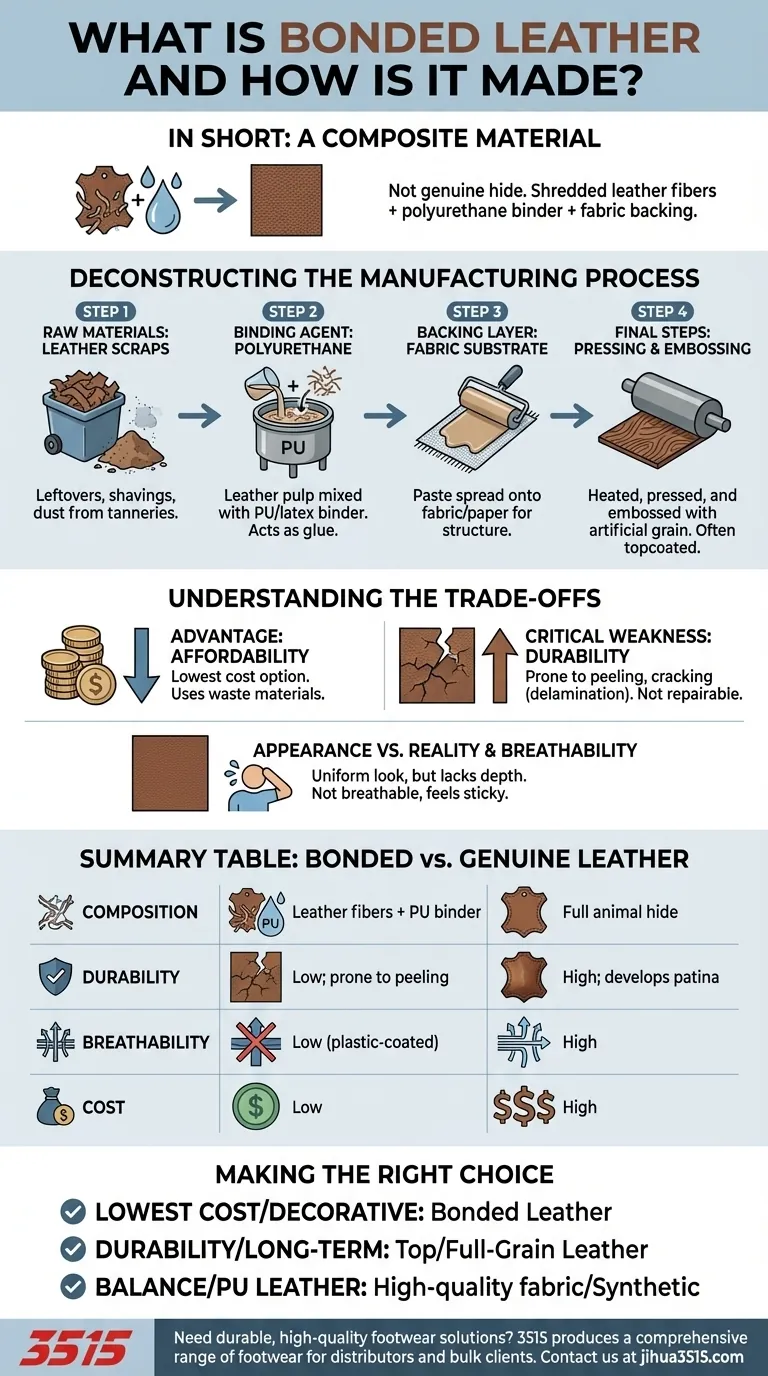

In short, bonded leather is a composite material, not a genuine leather hide. It is manufactured by shredding leftover leather scraps and fibers, mixing them with a bonding agent like polyurethane, and pressing the mixture onto a fabric or paper backing. A synthetic, leather-like texture is then embossed onto the surface.

While it contains real leather fibers, bonded leather's performance and durability are defined by its plastic components, not the leather within. It is best understood as a synthetic material that uses leather as a filler.

Deconstructing the Manufacturing Process

To truly understand the value and limitations of bonded leather, you must first understand how it's made. The process reveals why it behaves so differently from genuine leather.

The Raw Materials: Leather Scraps

The process begins with the leftovers from tanneries and leather goods factories. This includes scraps, shavings, and even dust from full-grain and top-grain leather production.

These fragments are collected and ground into a fine, fibrous pulp.

The Binding Agent: Polyurethane

This leather pulp is then thoroughly mixed with a liquid polyurethane (PU) or latex binder. This polymer acts as the glue that holds the leather fibers together, forming a semi-liquid paste.

The percentage of actual leather fibers in this mix can be very low, but the product can still be legally marketed as "bonded leather."

The Backing Layer: Fabric Substrate

This leather-polyurethane paste is then spread onto a backing material. This substrate, typically a piece of fabric or paper, provides the structural integrity that the leather pulp itself lacks.

The Final Steps: Pressing and Embossing

Finally, the material is heated and pressed to bond the pulp to the backing. A heavy roller embosses the surface with an artificial grain pattern to mimic the appearance of real leather.

A final layer of polyurethane is often applied as a topcoat to give it a consistent color and sheen.

Understanding the Trade-offs

The manufacturing process creates a material with a very specific set of advantages and critical disadvantages. Acknowledging these is key to avoiding disappointment.

The Advantage: Affordability

The primary driver for bonded leather's existence is cost. By using waste materials, manufacturers can produce a product that has the look and feel of leather for a fraction of the price of genuine hides.

This makes it an accessible option for budget-conscious buyers.

The Critical Weakness: Durability

The polyurethane surface and binder are the material's weakest points. With use, friction, and exposure to body oils or sunlight, this plastic layer will inevitably begin to crack, peel, and flake away.

This is often referred to as "delamination" and is not repairable. Unlike genuine leather, which develops a patina over time, bonded leather simply deteriorates.

Appearance vs. Reality

Initially, bonded leather has a very uniform and consistent appearance, which some may prefer over the natural imperfections of real leather.

However, it lacks the depth, richness, and unique character of a genuine hide. It also doesn't possess the characteristic smell of real leather.

Breathability and Comfort

Because it is coated in a layer of plastic, bonded leather is not breathable. This can cause it to feel hot, sticky, or clammy in warmer weather, much like vinyl or other synthetic materials.

Making the Right Choice for Your Goal

Your decision should be based entirely on your priorities for budget, use case, and longevity.

- If your primary focus is the lowest possible cost for a leather-like look: Bonded leather is a viable choice for decorative items or furniture in very low-traffic areas.

- If your primary focus is durability and long-term value: You must invest in top-grain or full-grain leather, as bonded leather will not withstand regular, daily use.

- If you are seeking a balance of durability and affordability: A high-quality fabric or a fully synthetic material (often called PU leather) can be a much more durable and reliable alternative.

Understanding that bonded leather is a synthetic-surfaced composite empowers you to align your purchase with your true expectations for performance and value.

Summary Table:

| Aspect | Bonded Leather | Genuine Leather |

|---|---|---|

| Composition | Leather fibers + polyurethane binder | Full animal hide |

| Durability | Low; prone to peeling/cracking | High; develops patina |

| Breathability | Low (plastic-coated) | High |

| Cost | Low | High |

| Best For | Low-traffic, budget-conscious uses | Long-term, high-durability needs |

Need durable, high-quality footwear solutions? As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, ensuring quality and reliability for your business. Contact us today to discuss your needs!

Visual Guide

Related Products

- Custom Manufactured Air Cushion Leather Business Shoes for Wholesale

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Wholesale Comfort Leather Business Shoes with Dial Lacing System

- Wholesale Classic Leather Lace-Up Ankle Boots for Brand Manufacturing

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

People Also Ask

- Can sneakers be part of a business casual wardrobe? Yes, with the right style and fit

- How does leather compare to other shoe materials in terms of durability and comfort? A Material Guide for Footwear

- Why are sneakers now accepted in office environments? The Shift to Modern Professionalism

- What are the key features of high-quality leather in shoes? Invest in Durability and a Perfect Fit

- Are sneakers acceptable in a business casual workplace? How to Choose the Right Style