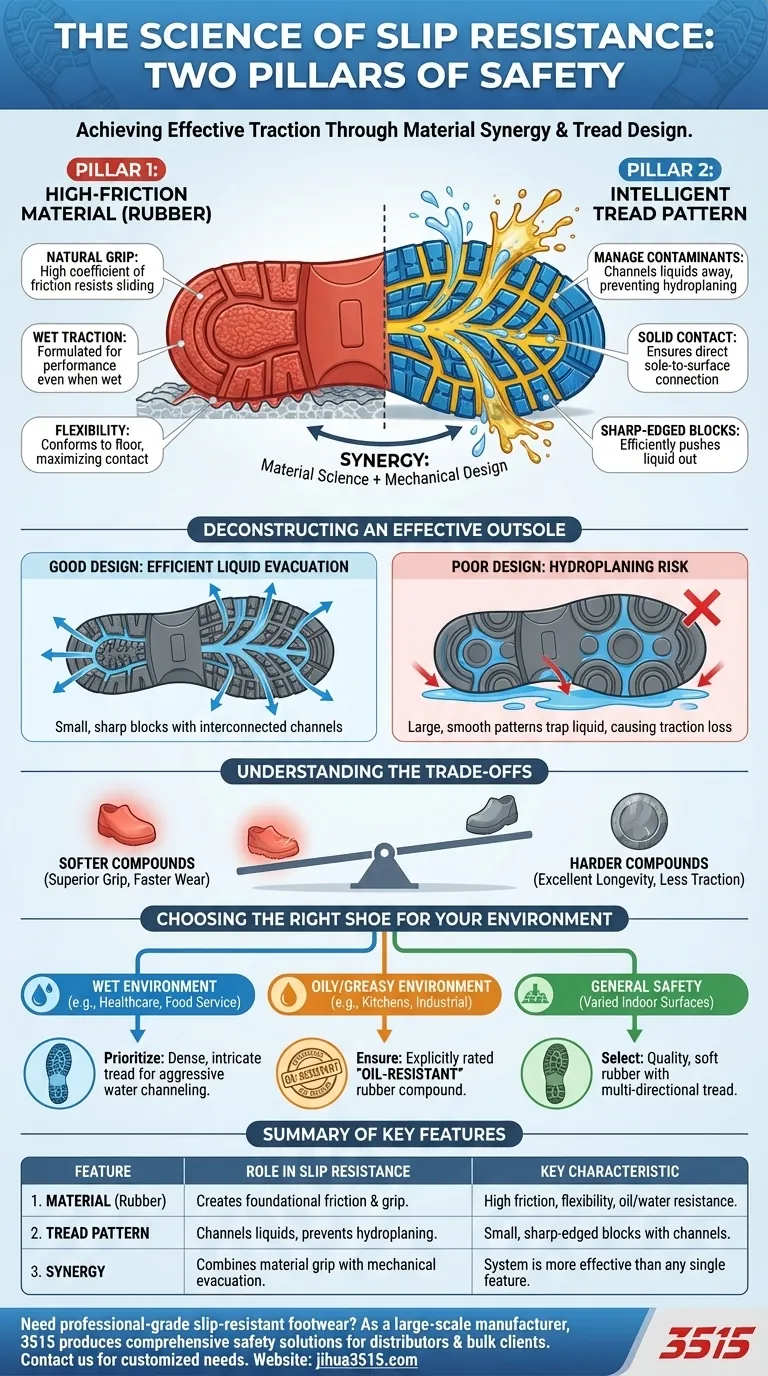

To achieve effective slip resistance, a shoe sole must combine two critical features: a high-friction material and an intelligent tread pattern. The material, typically a specialized rubber, creates the initial grip, while the tread design works to channel away liquids like water or oil. This prevents hydroplaning and ensures the sole maintains direct contact with the walking surface.

True slip resistance is not a single feature but a system. It's the synergy between a sole's material science—its inherent ability to grip—and its mechanical design—its capacity to clear contaminants from its path.

The Two Pillars of Slip Resistance

To properly evaluate a shoe's safety, you must understand the distinct but complementary roles of its sole material and its tread pattern. One cannot compensate for a major deficiency in the other.

The Role of Material: Creating Friction

The foundation of slip resistance is the compound used to create the outsole. The material's inherent ability to create friction against a surface is the first line of defense against a fall.

Rubber is a highly effective and common material for this purpose. Its molecular structure gives it a naturally high coefficient of friction, allowing it to grip surfaces tenaciously.

Furthermore, high-quality rubber compounds are engineered to be pliable, enabling them to conform to microscopic irregularities in a floor, which maximizes the surface area of contact.

The Role of Tread Design: Managing Contaminants

Even the best material will fail if a layer of liquid gets between it and the floor. This is where tread design becomes critical.

The primary function of a tread pattern is not to "dig in" but to channel water and other liquids away from the center of the sole. This ensures solid contact is maintained between the sole and the walking surface.

When a sole cannot evacuate water effectively, a thin film of liquid can lift the shoe off the surface, causing it to hydroplane—the same phenomenon that affects car tires on a wet road. This leads to a sudden and dangerous loss of traction.

Deconstructing an Effective Outsole

Knowing the principles is the first step. The next is recognizing how they are applied in a well-designed shoe, particularly for hazardous professional environments like kitchens, healthcare, or industrial settings.

Why Rubber is the Industry Standard

High-quality rubber outsoles are the benchmark for a reason. They provide a multi-faceted approach to traction that includes:

- Natural Grip: The material itself resists sliding.

- Wet Traction: It is formulated to maintain its frictional properties even when wet.

- Flexibility: It conforms to the floor, increasing contact.

- Engineered Compounds: It can be specialized for specific hazards, like oil in a commercial kitchen.

The Mechanics of a Good Tread Pattern

Effective tread patterns feature small, sharp-edged blocks with clear, interconnected channels leading to the outside of the sole. This design efficiently pushes liquid out from under the foot.

Conversely, poor designs often feature large, smooth, or circular patterns. These tread types can trap water under the shoe, which dramatically increases the risk of hydroplaning and subsequent falls.

Understanding the Trade-offs

No single shoe sole is perfect for every condition. Being an informed professional means recognizing the inherent compromises in different designs.

Durability vs. Grip

There is often a trade-off between the softness of the rubber and its durability. Softer rubber compounds tend to offer superior grip, especially on very smooth, wet surfaces, but they may wear down more quickly.

Harder compounds provide excellent longevity but may offer slightly less traction in demanding conditions. The choice depends on the specific workplace environment and the expected lifespan of the footwear.

Environment-Specific Design

A sole designed for a hospital hallway (primarily water) will have a different tread and compound than one designed for a greasy auto shop. An "oil-resistant" sole uses a specific rubber compound that won't degrade or swell when exposed to petrochemicals, a failure point for standard rubber.

How to Choose the Right Slip-Resistant Shoe

Make your selection based on a clear understanding of your primary work environment.

- If your primary focus is a wet environment (e.g., healthcare, food service): Prioritize a sole with a dense, intricate tread pattern designed to aggressively channel water away.

- If your primary focus is an oily or greasy environment (e.g., kitchens, industrial settings): Ensure the shoe is explicitly rated as "oil-resistant" and "slip-resistant" to guarantee the rubber compound is appropriate.

- If your primary focus is general safety on varied indoor surfaces: A quality, soft rubber outsole with a multi-directional tread pattern offers the most versatile protection.

By focusing on how a sole's material and design work together to manage real-world hazards, you can assess the true safety of your footwear beyond simple marketing claims.

Summary Table:

| Feature | Role in Slip Resistance | Key Characteristic |

|---|---|---|

| Material (e.g., Rubber) | Creates foundational friction and grip. | High coefficient of friction, flexibility, oil/water resistance. |

| Tread Pattern | Channels liquids away to prevent hydroplaning. | Small, sharp-edged blocks with interconnected channels. |

| Synergy | Combines material grip with mechanical liquid evacuation. | The system is more effective than any single feature alone. |

Need professional-grade slip-resistant footwear? As a large-scale manufacturer, 3515 produces a comprehensive range of safety shoes and boots for distributors, brand owners, and bulk clients. Our expertise in material science and tread design ensures your team has the right protection for any environment—from kitchens to industrial floors. Contact us today to discuss your specific needs and receive a customized solution.

Visual Guide

Related Products

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

People Also Ask

- Why is the use of specialized work boots with high comfort levels necessary for welding? Enhance Safety and Endurance

- How do non-slip protective shoes reduce accident rates in industrial workshops containing debris and scattered tools? Enhance Workshop Safety & Stability

- Why are industrial safety shoes necessary for mining machinery maintenance? Protect Feet from Crushing and Punctures

- What are the technical advantages of industrial-grade slip-resistant safety shoes? Prevent Falls with Engineered Grip

- How does wearing comprehensive safety apparel, including anti-slip boots, mitigate risks in Crude Palm Oil (CPO) storage tank areas? Ensure Operator Safety & Compliance.