Ultimately, a great motorcycle boot sole is an engineered system for safety and control. It must provide non-slip grip on unpredictable surfaces, resist chemical degradation from oil and fuel, support your foot on the pegs for hours, and be constructed to last for thousands of miles.

The ideal motorcycle boot sole is not defined by a single feature, but by a deliberate balance between grip, durability, and construction. Understanding this balance is the key to choosing a boot that provides confident control and long-term value.

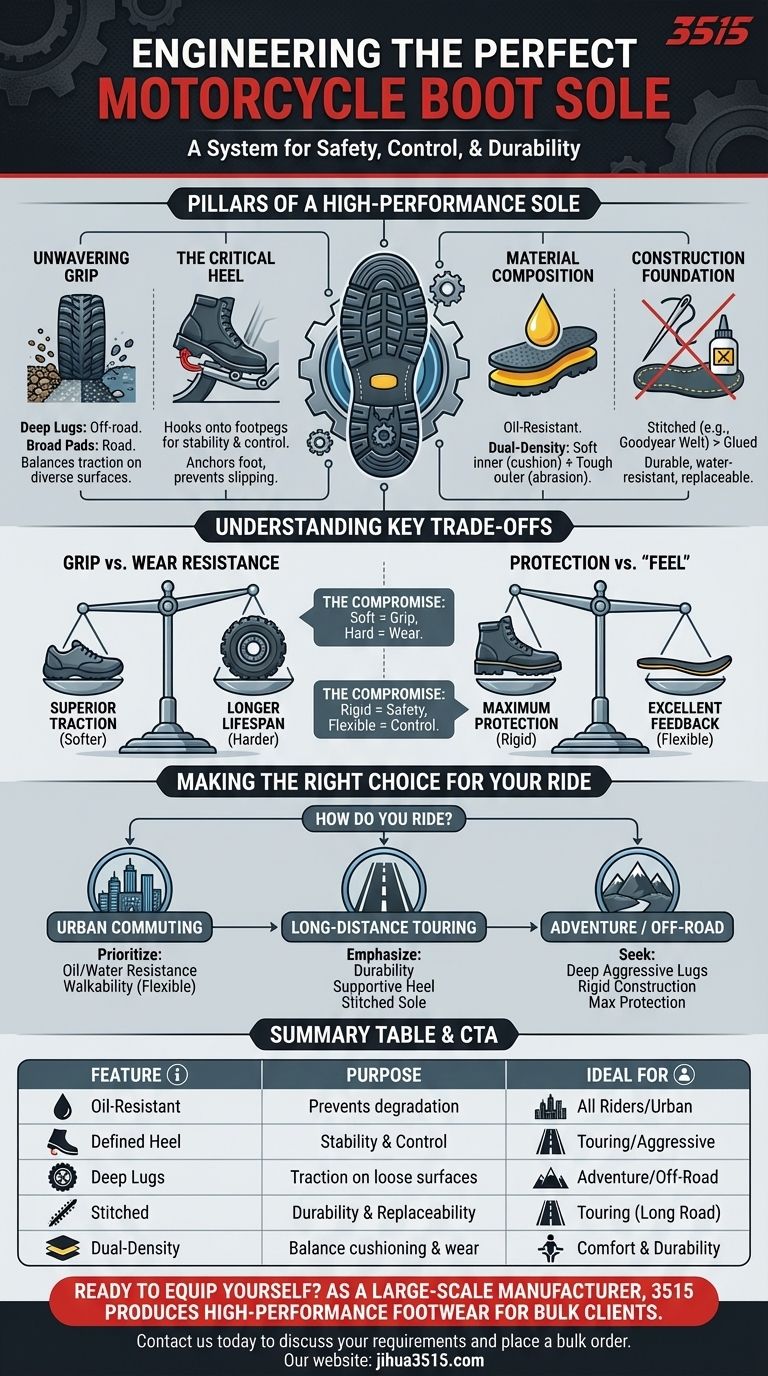

The Pillars of a High-Performance Sole

A motorcycle boot sole is your direct interface with both the machine and the ground. Its design is a matter of functional engineering, where each element serves a critical purpose for safety and performance.

Unwavering Grip and Traction

The primary job of any sole is to keep you upright. Motorcycle boots face a unique challenge, needing to provide grip on surfaces ranging from clean asphalt to oil-slicked pavement or loose gravel.

The tread pattern is designed for this reality. Deep lugs, similar to those on tactical or winter boots, are excellent for digging into soft ground like mud and sand, making them ideal for adventure riding. Broader contact pads are better suited for road riding, maximizing surface area on hard terrain.

The Critical Role of the Heel

Unlike many athletic shoes, nearly all proper riding boots feature a defined heel. This isn't just for aesthetics.

The heel is designed to hook securely onto the motorcycle's footpegs. This provides a stable anchor point, preventing your foot from slipping forward and ensuring you can maintain leverage and control, especially during aggressive maneuvers or long rides.

Material Composition: The Durability Equation

The material itself must be resilient. Oil-resistance is non-negotiable, as contact with fuel and lubricants can cause inferior rubber compounds to degrade, soften, and lose their integrity.

A good sole balances hardness and softness. A sole that is too hard will lack grip on smooth, wet surfaces. A sole that is too soft will provide excellent grip but wear out prematurely. Modern designs often use dual-density materials, with a softer inner layer for cushioning and a tougher outer layer for abrasion resistance and grip.

Construction: The Foundation of Longevity

How the sole is attached to the boot is just as important as the sole itself. This determines the boot's lifespan and repairability.

Stitched vs. Glued Soles

Many boots use cement or glue to attach the sole. While this is a cost-effective method, it is less durable and often makes replacement impossible.

A stitched-on sole, such as a Goodyear welt, is the gold standard. This method physically sews the sole to the boot's upper, creating an incredibly strong and water-resistant bond. More importantly, it allows a worn-out sole to be removed and replaced by a cobbler, significantly extending the life of your investment.

Understanding the Key Trade-offs

Choosing the perfect sole involves navigating inherent compromises. There is no single "best" sole, only the best sole for a specific purpose.

Grip vs. Wear Resistance

This is the most fundamental trade-off. Softer rubber compounds offer superior traction, conforming to microscopic imperfections in the road surface. However, this softness leads to faster wear.

Harder compounds, conversely, offer a much longer lifespan and resist abrasion well. The downside is a potential reduction in grip, especially in wet or cold conditions where the material can become less pliable.

Protection vs. "Feel"

A thick, rigid sole with a steel shank provides maximum protection from impacts and punctures. The trade-off is a reduction in flexibility, which can make it difficult to feel the motorcycle's controls and can be clumsy for walking.

A thinner, more flexible sole offers excellent feedback from the shifter and brake pedal. This enhances control but offers less protection from crush injuries or road hazards.

Making the Right Choice for Your Ride

Your ideal boot sole depends entirely on how and where you ride.

- If your primary focus is urban commuting: Prioritize a sole with excellent oil and water resistance for unpredictable city streets, along with enough flexibility for comfortable walking.

- If your primary focus is long-distance touring: Emphasize durability and a strong, supportive heel for long hours on the pegs, often found in boots with stitched, harder-wearing soles.

- If your primary focus is adventure or off-road riding: Seek a sole with deep, aggressive lugs for traction on loose surfaces and a rigid construction for maximum protection.

Ultimately, choosing the right sole is about matching the boot's engineered purpose to your personal riding needs.

Summary Table:

| Feature | Purpose | Ideal For |

|---|---|---|

| Oil-Resistant Rubber | Prevents degradation from fuel and lubricants | All riders, especially urban commuters |

| Defined Heel | Hooks onto footpegs for stability and control | Long-distance touring and aggressive riding |

| Deep Lugs / Aggressive Tread | Provides traction on loose surfaces like mud and gravel | Adventure and off-road riding |

| Stitched Construction (e.g., Goodyear Welt) | Ensures durability and allows for sole replacement | Touring riders seeking long-term value |

| Dual-Density Material | Balances cushioning (inner layer) with abrasion resistance (outer layer) | Riders needing a balance of comfort and durability |

Ready to equip yourself with the perfect motorcycle boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of motorcycle boots and boots, engineered with the precise balance of grip, durability, and construction detailed above.

We provide reliable, high-quality footwear solutions tailored to your market's needs. Contact us today to discuss your requirements and place a bulk order.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What safety standards should firefighting boots meet? NFPA 1971 Compliance for Maximum Protection

- How should tactical boots be maintained and cleaned? Extend Boot Lifespan with a Proactive Care System

- What is the purpose of the rigid plastic box in smart insoles? Protecting Electronics in Tactical Footwear

- What factors should be considered when choosing tactical boots for different terrains? Match Your Boot to the Mission.

- What is the function of the insole in tactical boots? A Guide to Foot Support & Performance

- What is the primary function of haptic feedback in tactical boots? Enhance Training with Real-Time Physical Guidance

- What are the main benefits of tactical boots? Superior Protection, Comfort & Durability

- Are combat boots suitable for civilian use? A Guide to Durability, Style, and Practicality