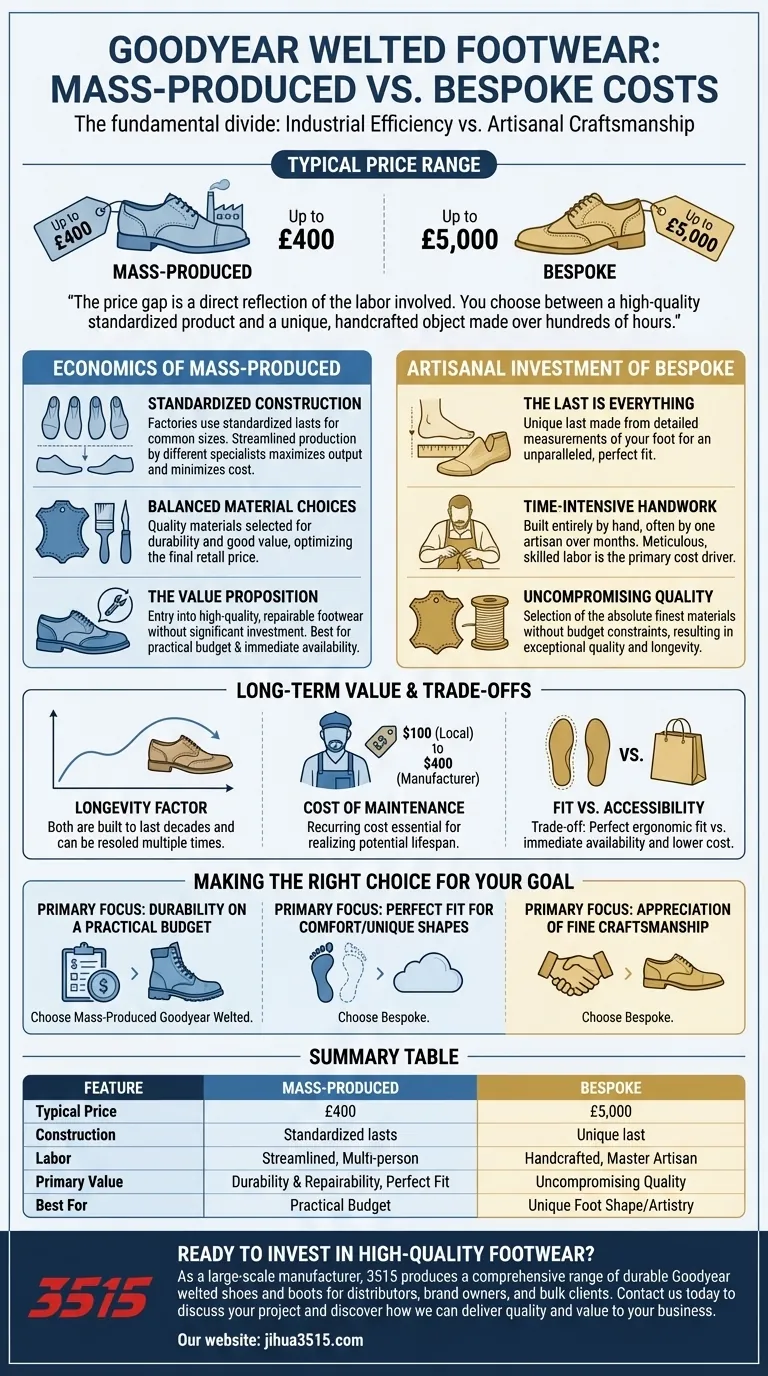

At its core, the cost difference between mass-produced and bespoke Goodyear welted shoes is vast, reflecting a fundamental divide between industrial efficiency and artisanal craftsmanship. A mass-produced pair typically retails for up to £400, while a bespoke pair, built entirely around your individual foot, can cost as much as £5,000.

The price gap isn't just about materials; it's a direct reflection of the labor involved. You are choosing between a high-quality, standardized product and a unique, handcrafted object made by a master artisan over hundreds of hours.

The Economics of Mass-Produced Welted Shoes

Mass production brings the durable Goodyear welt construction to a broader market by optimizing for efficiency and scale. The goal is to produce a reliable, repairable shoe at an accessible price point.

Standardized Construction

Factories use standardized lasts (the forms that give shoes their shape) across a range of common sizes. This allows for streamlined production lines where different specialists handle distinct parts of the process, maximizing output and minimizing cost.

Balanced Material Choices

Manufacturers select quality materials, but always with an eye on the final retail price. The leather and components are chosen to provide good durability and value, creating a product that significantly outperforms cheaper, cemented shoes.

The Value Proposition

At a price point around £400, these shoes represent an entry into high-quality, long-lasting footwear. You get the primary benefit of the Goodyear welt—repairability—without the significant investment required for a custom-made item.

The Artisanal Investment of Bespoke Shoes

Bespoke shoemaking is a traditional craft focused on creating a perfect, one-of-a-kind product for a single client. The cost is almost entirely a function of the master craftsperson's time and skill.

The Last is Everything

The process begins with the shoemaker taking detailed measurements of your feet to create a unique wooden last. This last is a perfect model of your foot, ensuring an unparalleled fit that mass-produced shoes cannot replicate.

Time-Intensive Handwork

A bespoke pair is built by hand, often by a single artisan, over many months. Every step, from cutting the leather to stitching the welt, is a meticulous, time-consuming process that demands immense skill. This skilled labor is the primary driver of the high cost.

Uncompromising Quality

In the bespoke world, there are no compromises. The shoemaker selects the absolute finest materials available, from the highest-grade leather hides to the strongest linen thread, without being constrained by a budget. This results in a shoe of exceptional quality and longevity.

Understanding the Trade-offs

While the upfront cost is the most obvious difference, the long-term value and maintenance costs are critical factors in the overall equation.

The Longevity Factor

Both types of Goodyear welted shoes are built to last for decades, far outliving their cheaper counterparts. The ability to resole the shoe means the upper, which has molded to your foot, can be preserved through multiple new soles.

The Cost of Maintenance

Resoling is a key part of long-term ownership. This can cost anywhere from around $100 for a local cobbler to $400 if you send the shoes back to the original high-end manufacturer for a full refurbishment. This recurring cost is essential to realizing the shoe's potential lifespan.

Fit vs. Accessibility

The fundamental trade-off is between the perfect, ergonomic fit of a bespoke shoe and the immediate availability and lower cost of a mass-produced one. The "better" option depends entirely on your personal priorities and budget.

Making the Right Choice for Your Goal

Your decision should be guided by what you value most in a pair of shoes: accessibility, fit, or craftsmanship.

- If your primary focus is durability on a practical budget: A mass-produced Goodyear welted shoe offers the best long-term value proposition.

- If your primary focus is a perfect fit to address comfort issues or unique foot shapes: The investment in a bespoke shoe is unmatched and often necessary.

- If your primary focus is the appreciation of fine craftsmanship and personalization: The bespoke process provides a unique product and experience that cannot be replicated by a factory.

Ultimately, choosing a Goodyear welted shoe at any price point is an investment in quality and sustainability over disposable fashion.

Summary Table:

| Feature | Mass-Produced | Bespoke |

|---|---|---|

| Typical Price | Up to £400 | Up to £5,000 |

| Construction | Standardized lasts, efficient production | Unique last made from your foot measurements |

| Labor | Streamlined, multi-person assembly line | Handcrafted by a master artisan over hundreds of hours |

| Primary Value | Durability and repairability at an accessible price | Perfect fit, uncompromising quality, and unique craftsmanship |

| Best For | Practical budget, immediate availability, long-term value | Unique foot shape, ultimate comfort, appreciation of artistry |

Ready to Invest in High-Quality Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable Goodyear welted shoes and boots for distributors, brand owners, and bulk clients. Whether you need reliable, cost-effective stock or are developing a premium line, our production capabilities encompass all types of footwear to meet your market's demands.

Contact us today to discuss your project and discover how we can deliver quality and value to your business.

Visual Guide

Related Products

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Breathable Perforated Leather Derby Dress Shoes for Custom Brands

- Durable Waterproof Rain Boots | Custom Manufacturer for Wholesale & Brands

People Also Ask

- How can high-quality tactical or athletic footwear mitigate social participation restrictions? Enhance Your Mobility

- How does the integration of advanced functional composite materials in Training and Outdoor shoes protect market share?

- What is the benefit of using a multi-functional training station for CRT? Maximize Efficiency & Metabolic Health

- What role do professional training shoes play during HIIT for adolescent athletes? Stability and Injury Prevention

- Why are professional training shoes critical for safety? Expert Guide to Plyometric Stability and Performance