The primary hazards faced by oilfield workers are a complex mix of physical, chemical, and environmental dangers. These risks stem directly from the nature of the work, which involves heavy machinery, high-pressure systems, volatile substances, and operations in extreme and often remote locations. The most immediate dangers include being struck by or caught between heavy equipment, falls from slippery surfaces, and exposure to hazardous chemicals.

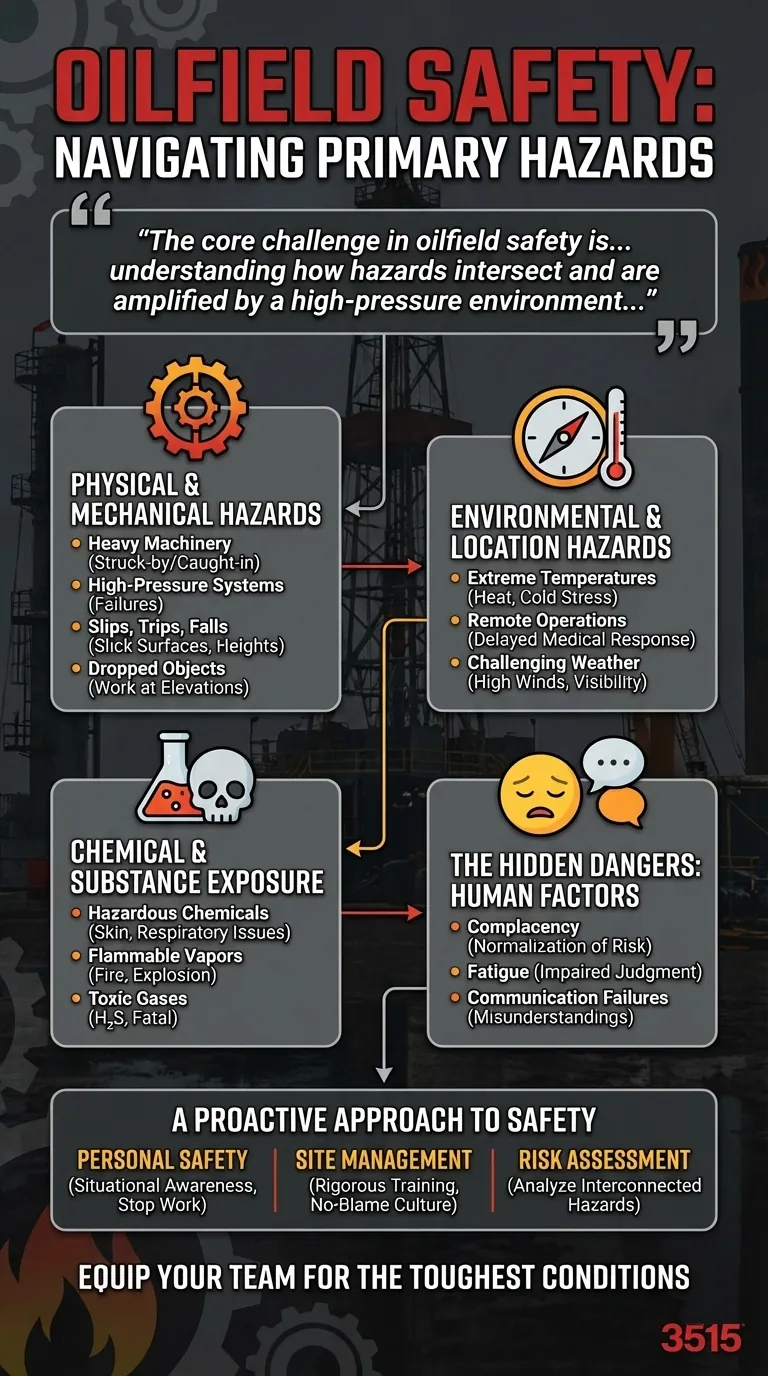

The core challenge in oilfield safety is not just managing individual hazards, but understanding how they intersect and are amplified by a high-pressure environment where fatigue and remote working conditions can turn a minor issue into a critical incident.

The Pillars of Oilfield Risk

To truly grasp the safety landscape, we must break down the hazards into four key categories. Each presents a unique set of challenges that require constant vigilance and rigorous safety protocols.

Physical and Mechanical Hazards

This category includes the most common and immediate threats on any oil and gas site. They are tangible dangers related to the equipment and physical environment.

Heavy Machinery: Equipment like drill rigs, pumps, and cranes creates significant risks for "struck-by" or "caught-in/between" incidents, which are among the leading causes of serious injury.

High-Pressure Systems: Pipes, lines, and vessels operate under immense pressure. A failure can result in a catastrophic blowout, releasing fluids or gases with explosive force and causing severe equipment damage or injury.

Slips, Trips, and Falls: Work surfaces are often slick with oil, mud, water, or ice. Combined with uneven terrain and work at heights on platforms and rigs, this makes falling a constant and serious danger.

Dropped Objects: Work is frequently performed at multiple elevations. Any tool, part, or piece of equipment dropped from above can be lethal to personnel working below.

Environmental and Location-Based Hazards

Oil and gas exploration often takes place in the world's most inhospitable environments, adding another layer of risk to daily operations.

Extreme Temperatures: Workers face severe heat stress and dehydration in desert locations, while those in arctic or offshore environments must contend with hypothermia and frostbite.

Remote Operations: Many sites are far from advanced medical facilities. This remoteness significantly increases the severity of any injury, as response times for emergency services are much longer.

Challenging Weather: Operations often continue through high winds, heavy rain, or snow, which increases the risk of falls, impairs visibility, and adds stress to both workers and equipment.

Chemical and Substance Exposure

The extraction and processing of oil and gas involve a wide array of dangerous substances that can cause immediate or long-term harm.

Hazardous Chemicals: Workers handle drilling fluids, solvents, and other industrial chemicals that can cause skin irritation, respiratory issues, or other health problems with improper handling.

Flammable Vapors: The release of hydrocarbons can create an explosive atmosphere. Any ignition source, from a spark from a tool to static electricity, can trigger a fire or explosion.

Toxic Gases: Hydrogen Sulfide (H₂S), a naturally occurring gas in oil and gas formations, is a primary concern. It is highly toxic even at low concentrations and can be instantly fatal.

The Hidden Dangers: Complacency and Fatigue

Beyond the physical hazards are human factors that can undermine even the most robust safety systems. These are often the root causes of major incidents.

The Normalization of Risk

When workers are exposed to serious hazards daily, it's possible to become desensitized. This "normalization of risk" can lead to shortcuts or a failure to follow safety procedures, as the sense of immediate danger fades over time.

The Impact of Fatigue

Long shifts, often 12 hours or more for weeks at a time, lead to physical and mental fatigue. A tired worker has slower reaction times, impaired judgment, and is more likely to make a critical error when operating machinery or making decisions.

Failures in Communication

A clear line of communication is critical, especially during shift changes or complex, multi-team operations. A misunderstanding about the state of a valve, the position of a piece of equipment, or a procedural step can have disastrous consequences.

A Proactive Approach to Oilfield Safety

Understanding these hazards is the first step. Applying that knowledge requires a commitment to a proactive safety culture from every person on site.

- If your primary focus is personal safety: Prioritize constant situational awareness, meticulously follow procedures, and never hesitate to use your "Stop Work Authority" if you feel a task is unsafe.

- If your primary focus is site management: Implement rigorous, hands-on training, strictly enforce all safety protocols, and cultivate a "no-blame" culture where reporting near-misses is encouraged for learning.

- If your primary focus is risk assessment: Analyze how hazards are interconnected—recognizing that fatigue can lead to a procedural error, which in turn could cause a high-pressure line failure.

A deep and practical understanding of these interconnected risks is the foundation of a truly safe work environment.

Summary Table:

| Hazard Category | Key Risks |

|---|---|

| Physical & Mechanical | Struck-by/caught-in incidents, high-pressure system failures, slips/trips/falls, dropped objects. |

| Environmental & Location | Extreme temperatures, remote operations, challenging weather conditions. |

| Chemical & Substance | Exposure to hazardous chemicals, flammable vapors, toxic gases like H₂S. |

| Human Factors | Complacency, fatigue, communication failures. |

Equip Your Team for the Toughest Conditions

Understanding these risks is critical, but having the right protective equipment is the first line of defense. As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality, durable safety footwear specifically designed for the oilfield environment. Our boots offer superior slip resistance, puncture protection, and metatarsal guards to mitigate the physical hazards your teams face daily.

We provide reliable footwear solutions for distributors, brand owners, and bulk clients, ensuring your workforce is protected from the ground up.

Contact 3515 today to discuss your safety footwear needs and receive a customized product recommendation.

Visual Guide

Related Products

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Premium Grain Leather Safety Boots for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- Why are industrial safety shoes necessary for mining machinery maintenance? Protect Feet from Crushing and Punctures

- What are the technical advantages of industrial-grade slip-resistant safety shoes? Prevent Falls with Engineered Grip

- Why is the use of specialized work boots with high comfort levels necessary for welding? Enhance Safety and Endurance

- Why is specialized personal protective equipment required for specific industries? Enhancing Safety in Heavy Industry

- How do non-slip protective shoes reduce accident rates in industrial workshops containing debris and scattered tools? Enhance Workshop Safety & Stability