From start to finish, a single pair of Goodyear welted shoes can take up to four days to manufacture. This extended timeline is not due to inefficiency but is a direct result of a meticulous and complex process involving over 120 individual steps, each performed by highly specialized craftspeople.

The lengthy manufacturing time of a Goodyear welted shoe is a deliberate feature, not a flaw. It reflects a construction method that prioritizes unmatched durability, water resistance, and repairability over mass-produced speed.

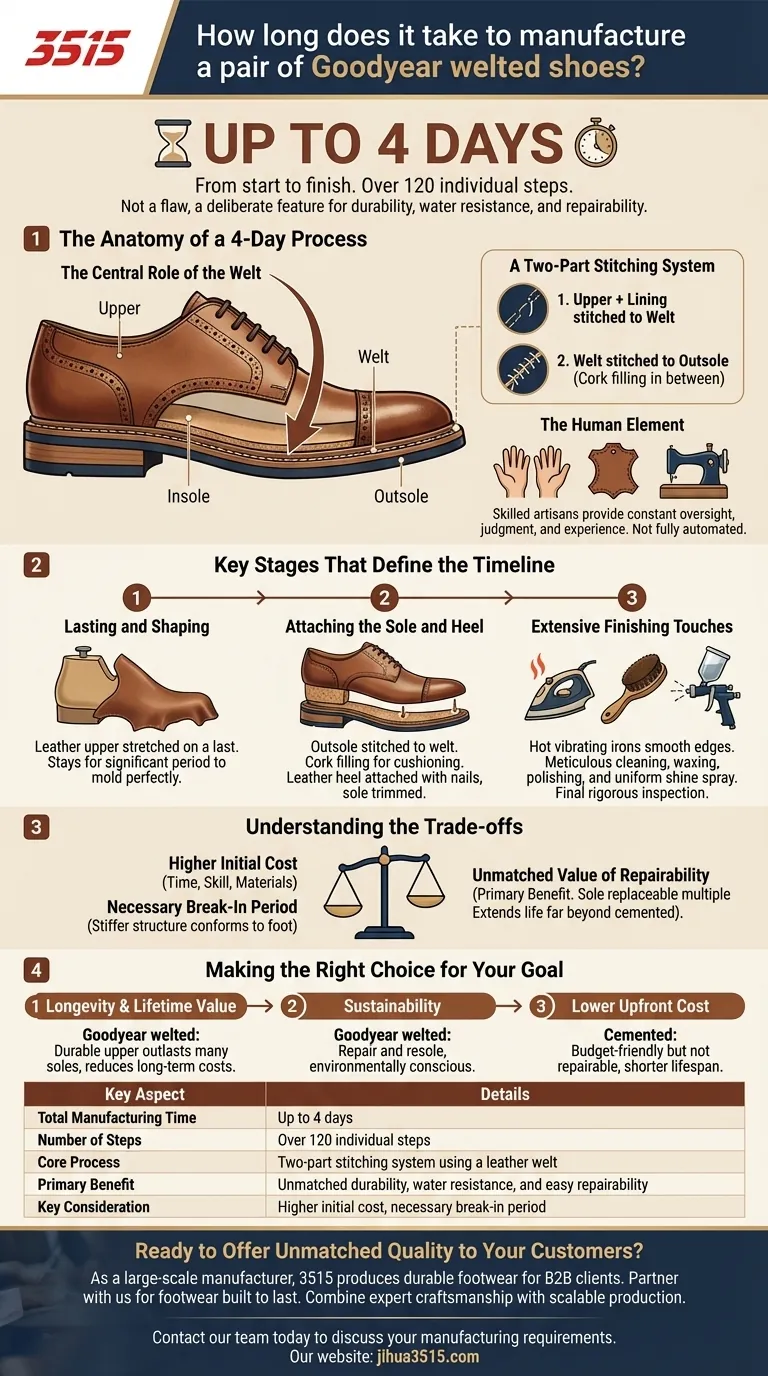

The Anatomy of a 4-Day Process

The time required to create a Goodyear welted shoe is rooted in its unique structural design. Unlike shoes where the sole is simply glued on, this method builds a robust and serviceable foundation.

The Central Role of the Welt

At the core of the process is the welt, a narrow strip of leather that runs along the perimeter of the outsole.

The welt acts as an intermediary, connecting the upper part of the shoe to the sole with two independent stitches. This creates a remarkably strong and stable bond.

A Two-Part Stitching System

First, the upper leather and lining are stitched to the welt. Then, in a separate step, the welt is stitched to the outsole.

This two-level stitching method is what makes the shoe so durable and, critically, easy to resole. A cobbler can cut the outsole stitch without ever compromising the upper.

The Human Element

While machines can assist, the process demands constant oversight and intervention from skilled artisans.

Tasks like shaping the leather over the last, guiding the stitching, and applying the finishing touches all require a level of judgment and experience that cannot be fully automated.

Key Stages That Define the Timeline

Several specific, time-consuming stages contribute to the multi-day manufacturing cycle. Each is essential for creating the final product's signature quality.

Lasting and Shaping

The leather upper is stretched tightly over a foot-shaped form called a last. The shoe remains on the last for a significant period, allowing the leather to mold perfectly into its final, permanent shape.

Attaching the Sole and Heel

Once the welt is in place, the outsole is stitched on. The cavity between the insole and outsole is typically filled with cork, which provides cushioning and molds to the wearer's foot over time.

Finally, the leather heel is carefully attached with nails, and the entire sole is trimmed to its final shape.

Extensive Finishing Touches

A significant portion of the time is dedicated to finishing. This includes using hot vibrating irons to smooth and polish the sole edges, meticulously cleaning the upper, and applying multiple layers of wax and polish.

The shoes are then sprayed to achieve a uniform shine before a final, rigorous inspection.

Understanding the Trade-offs

The Goodyear welt method is a benchmark for quality, but its intensive process comes with specific considerations.

Higher Initial Cost

The sheer number of steps and the high level of required craftsmanship directly contribute to a higher price point compared to simpler construction methods. You are paying for time, skill, and durable materials.

A Necessary Break-In Period

The robust internal structure, including the welt and cork filling, often results in a stiffer shoe out of the box. This break-in period is necessary for the shoe to conform to your foot, ultimately creating a personalized fit.

The Unmatched Value of Repairability

This is the primary benefit that justifies the cost and break-in period. Because the sole is stitched to the welt and not the upper, a worn-out sole can be replaced multiple times. This dramatically extends the functional life of the shoe far beyond cemented alternatives.

Making the Right Choice for Your Goal

The decision to invest in a Goodyear welted shoe should align with your long-term priorities for your footwear.

- If your primary focus is longevity and lifetime value: A Goodyear welted shoe is a sound investment, as the durable upper can outlast many soles, reducing long-term replacement costs.

- If your primary focus is sustainability: The ability to repair and resole the shoe, rather than discard it, makes it a more environmentally conscious choice.

- If your primary focus is a lower upfront cost: Simpler, cemented shoe constructions will be more budget-friendly, but they are typically not repairable and will have a much shorter lifespan.

Understanding the time and skill invested in its creation allows you to see a Goodyear welted shoe not merely as footwear, but as a durable, long-term asset.

Summary Table:

| Key Aspect | Details |

|---|---|

| Total Manufacturing Time | Up to 4 days |

| Number of Steps | Over 120 individual steps |

| Core Process | Two-part stitching system using a leather welt |

| Primary Benefit | Unmatched durability, water resistance, and easy repairability |

| Key Consideration | Higher initial cost, necessary break-in period |

Ready to Offer Unmatched Quality to Your Customers?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including the meticulous Goodyear welted construction.

Partner with us to provide your customers with footwear built to last. We combine expert craftsmanship with scalable production to meet your quality and volume needs.

Contact our team today to discuss your manufacturing requirements and discover how we can add value to your product line.

Visual Guide

Related Products

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- Why is comfort important in dress shoes? Achieve All-Day Support for Professional Performance

- What should someone do if they are unsure about a company's dress code? Navigate with Confidence

- Are brown dress shoes appropriate for formal events? A Guide to Choosing the Right Shoe

- How should dress shoes be maintained to prolong their lifespan? A Guide to Lasting Quality

- What shoes are acceptable for business casual? A Guide to Polished & Professional Footwear