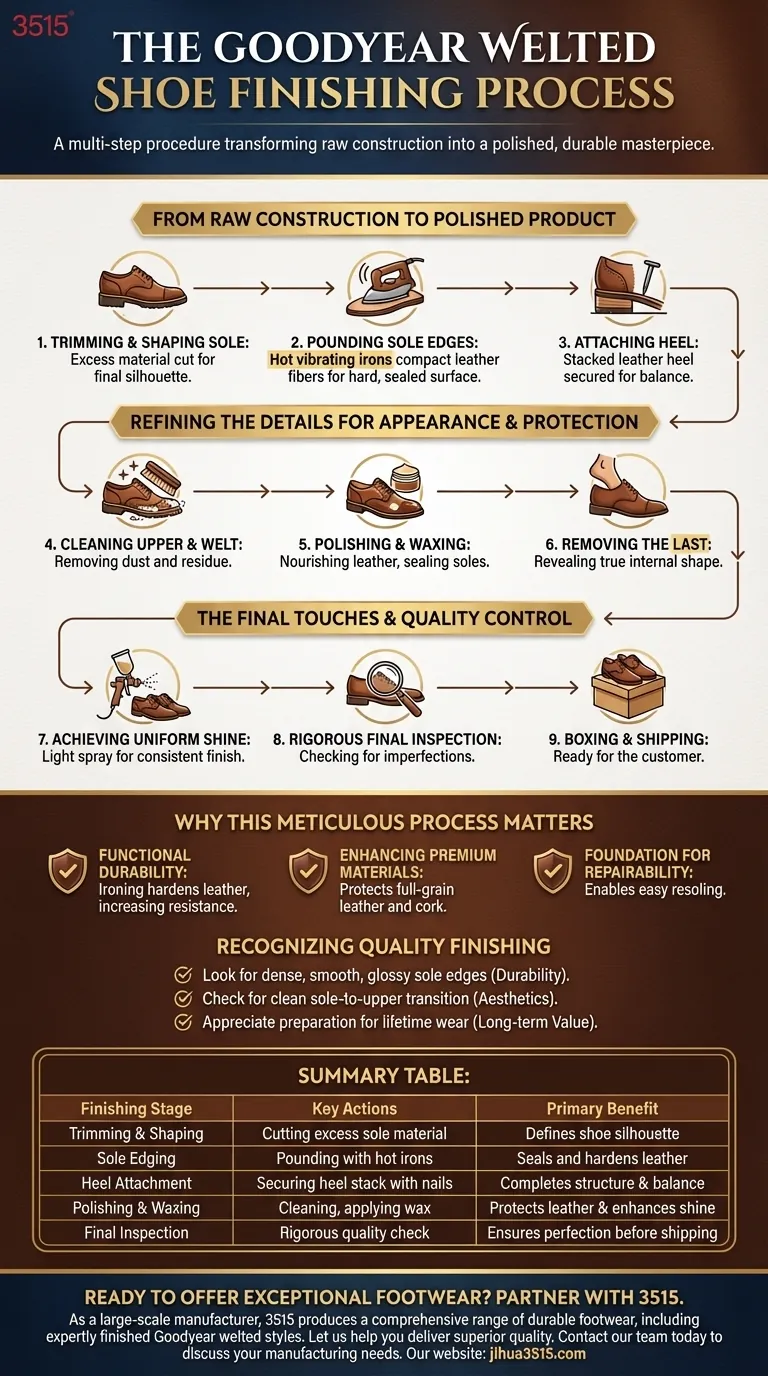

The finishing process for a Goodyear welted shoe is a multi-step procedure that transforms it from a raw, constructed object into a polished, durable final product. It involves trimming the sole, pounding the edges with hot irons for a smooth finish, attaching the heel, cleaning and polishing the uppers and welt, and applying a final wax and spray before a rigorous inspection.

The final finishing is not merely cosmetic; it is a critical stage that seals the shoe's construction, enhances the durability of the materials, and establishes the refined aesthetic that defines high-quality footwear.

From Raw Construction to Polished Product

The initial finishing steps focus on shaping and securing the shoe's foundation—the sole and heel. This stage sets the final profile and structural integrity of the shoe.

Trimming and Shaping the Sole

Once the outsole is stitched to the welt, the excess material is carefully trimmed away. This step ensures the sole perfectly follows the contours of the shoe last, defining its final silhouette.

Pounding the Sole Edges

Specialized hot vibrating irons are used to pound the trimmed edges of the leather sole. This intense pressure and heat compact the leather fibers, creating a hard, smooth, and sealed surface that is more resistant to moisture and wear.

Attaching the Heel

The heel, typically made of stacked leather, is securely attached to the sole with nails. This completes the core structure of the shoe, providing balance and the correct posture for the wearer.

Refining the Details for Appearance and Protection

With the main structure complete, the focus shifts to the finer details that protect the leather and create a pristine appearance.

Cleaning the Upper and Welt

The uppers and the exposed welt are thoroughly cleaned to remove any dust or adhesive residue left over from the construction process. This prepares the surface for polishing.

Polishing and Waxing

The uppers are polished to nourish the leather and begin building a protective, lustrous layer. Simultaneously, the soles are treated with wax to further seal them from the elements.

Removing the Last

At this stage, the last—the foot-shaped form the shoe was built around—is finally removed. This reveals the shoe's true internal shape and fit for the first time.

The Final Touches and Quality Control

The last steps ensure the shoe is perfect and ready for the customer. It's a final quality gate that upholds the maker's standard.

Achieving a Uniform Shine

The shoes are often given a light spray treatment. This ensures a completely uniform shine and color consistency across the entire pair before they are boxed.

Rigorous Final Inspection

Each shoe undergoes a meticulous final inspection. Craftsmen check for any imperfections in the stitching, finishing, or materials to ensure it meets the highest quality standards.

Boxing and Shipping

Only after passing inspection are the shoes carefully wrapped, boxed, and prepared for shipping to the customer.

Why This Meticulous Process Matters

The finishing process is far more than a simple polish; it's integral to the shoe's longevity and performance.

It's More Than Just Looks

Steps like ironing the sole edges are functional. They harden the leather, making it significantly more durable and resistant to water ingress, which directly contributes to the shoe's lifespan.

Enhancing High-Quality Materials

Goodyear welted shoes use premium materials like full-grain leather uppers and cork filling. The finishing process is tailored to protect and enhance these materials, ensuring the cork is sealed and the leather is conditioned.

A Foundation for Repairability

A clean, well-executed finish is a sign of solid underlying construction. This precision makes the shoe easier to resole in the future, which is the cornerstone benefit of the Goodyear welt method.

Recognizing Quality Finishing

When examining a pair of Goodyear welted shoes, the finish can tell you a lot about its quality.

- If your primary focus is durability: Look for dense, smooth, and glossy sole edges, which indicate they have been properly ironed and sealed.

- If your primary focus is aesthetics: Check for a clean transition between the sole edge and the upper, with no polish or wax smudged onto the leather.

- If your primary focus is long-term value: Appreciate that these finishing steps are what prepare the shoe for a lifetime of wear, justifying the initial investment.

Ultimately, the finishing process is the final act of craftsmanship that elevates a well-constructed shoe into a truly exceptional and lasting product.

Summary Table:

| Finishing Stage | Key Actions | Primary Benefit |

|---|---|---|

| Trimming & Shaping | Cutting excess sole material | Defines shoe silhouette |

| Sole Edging | Pounding with hot irons | Seals and hardens leather for durability |

| Heel Attachment | Securing heel stack with nails | Completes structure and balance |

| Polishing & Waxing | Cleaning uppers, applying wax | Protects leather and enhances shine |

| Final Inspection | Rigorous quality check | Ensures perfection before shipping |

Ready to Offer Exceptional Footwear? Partner with 3515.

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including expertly finished Goodyear welted styles designed for long-term value and customer satisfaction.

Let us help you deliver superior quality. Contact our team today to discuss your manufacturing needs and how we can bring lasting value to your product line.

Visual Guide

Related Products

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Patent Oxford Dress Shoes | Custom & Bulk Manufacturing

- Wholesale Comfort Leather Business Shoes with Dial Lacing System

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What types of dress shoes are recommended for formal occasions? A Guide to Impeccable Style

- What should someone do if they are unsure about a company's dress code? Navigate with Confidence

- What are the long-term benefits of investing in quality dress shoes? Save Money & Boost Your Style

- Why is comfort important in dress shoes? Achieve All-Day Support for Professional Performance

- What shoes are acceptable for business casual? A Guide to Polished & Professional Footwear