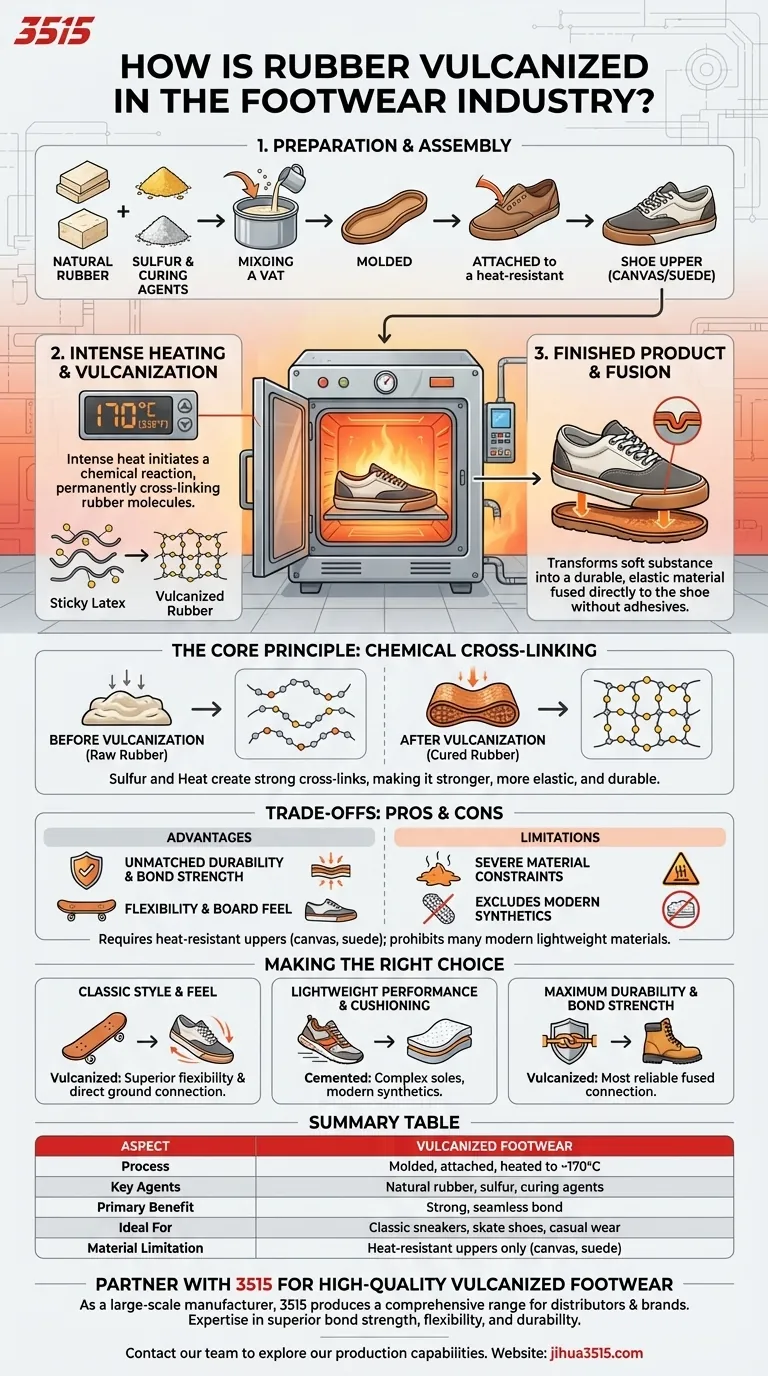

To vulcanize rubber for footwear, a mixture of natural rubber, sulfur, and other curing agents is molded into the shape of a sole and attached to the shoe's upper. The entire assembly is then heated in an oven to approximately 170° Celsius (338° Fahrenheit). This intense heat initiates a chemical reaction that permanently cross-links the rubber's molecules, transforming it from a soft, sticky substance into a durable, elastic material that fuses directly to the shoe.

The core concept to grasp is that vulcanization is not just a material treatment—it's a manufacturing method. It creates an incredibly strong, glue-less bond between the sole and the shoe but imposes significant heat-related limitations on the other materials that can be used in the design.

The Core Principle of Vulcanization

From Sticky Latex to a Stable Sole

Natural rubber in its raw state is a sticky, unstable polymer that is not practical for most applications. Vulcanization is the chemical process that solves this problem.

By introducing sulfur and heat, you create strong cross-links between the long polymer chains of the rubber. This molecular change permanently sets the material, making it stronger, more elastic, and significantly more durable.

The Role of Heat and Curing Agents

Sulfur is the classic and most critical curing agent in this process. However, the chemical reaction won't begin without a catalyst.

Heat is that catalyst. The industry standard temperature of 170°C provides the energy needed to force the sulfur to bond with the rubber polymers, completing the transformation from a soft compound into a tough, finished product.

Fusing Parts Without Adhesives

A key advantage of vulcanization in footwear is its ability to create a powerful bond without traditional cements or glues.

During the heating process, the rubber sole essentially melts and cures directly onto the shoe's upper (typically a durable material like canvas). This creates a single, unified piece with a seamless and incredibly strong connection, reducing the risk of the sole separating over time.

Understanding the Trade-offs

Advantage: Unmatched Durability and Bond Strength

The primary benefit of a vulcanized sole is its durability. The fusion of the sole to the upper creates a shoe that is highly resistant to delamination and separation.

This toughness is why the process is not only used for classic sneakers but also for demanding applications like vehicle tires, where reliability and resilience are paramount.

Advantage: Flexibility and Board Feel

Vulcanized construction results in a relatively simple, flexible sole. This is highly valued in skate shoes and other casual sneakers where feeling the ground or a skateboard beneath your feet is important for control and feedback.

Limitation: Severe Material Constraints

The greatest drawback of vulcanization is the intense heat required. A temperature of 170°C will melt or deform many modern, lightweight synthetic materials used in performance footwear.

This constraint is why vulcanized shoes are almost always made with heat-resistant uppers like canvas or suede. It effectively prohibits the use of advanced plastics, meshes, and foams found in modern running shoes.

Making the Right Choice for Your Footwear

The construction method directly impacts a shoe's performance and purpose.

- If your primary focus is classic style and board feel: A vulcanized shoe offers superior flexibility and a direct connection to the ground, making it ideal for skateboarding and casual wear.

- If your primary focus is lightweight performance and cushioning: A cemented (glued) construction is necessary, as it allows for complex, multi-layered soles and the use of modern, heat-sensitive synthetic materials.

- If your primary focus is maximum durability against sole separation: The fused bond of a vulcanized shoe provides one of the most reliable connections between the sole and the upper available.

Ultimately, knowing how a shoe is constructed empowers you to choose the right tool for your specific goal.

Summary Table:

| Aspect | Vulcanized Footwear |

|---|---|

| Process | Sole is molded, attached to upper, and heated to ~170°C (338°F) |

| Key Agents | Natural rubber, sulfur, and curing agents |

| Primary Benefit | Creates a strong, seamless bond between sole and upper |

| Ideal For | Classic sneakers, skate shoes, casual wear requiring flexibility and durability |

| Material Limitation | Uppers must be heat-resistant (e.g., canvas, suede); excludes many modern synthetics |

Need Durable, High-Quality Vulcanized Footwear for Your Market?

As a large-scale manufacturer, 3515 produces a comprehensive range of vulcanized footwear for distributors, brand owners, and bulk clients. Our expertise ensures superior bond strength, classic flexibility, and unmatched durability for your product line.

Let's discuss your project: Contact our team today to explore how our production capabilities can bring your vision to life.

Visual Guide

Related Products

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Safety Shoes with Rotating Buckle Safety Sneakers

- Premium KPU Injection Athletic Style Safety Shoes

People Also Ask

- How can high-quality tactical or athletic footwear mitigate social participation restrictions? Enhance Your Mobility

- Why are professional training shoes critical for safety? Expert Guide to Plyometric Stability and Performance

- How do safety harnesses assist in high-intensity treadmill testing? Ensure Data Validity for High-Performance Footwear

- How do specialized training shoes and sneakers support high-intensity training? Maximize Performance & Stability

- What is the benefit of using a multi-functional training station for CRT? Maximize Efficiency & Metabolic Health