At their core, safety shoes mitigate electrical hazards by using non-conductive materials to insulate your body from the ground. This prevents you from becoming the path of least resistance for an electrical current, effectively stopping a potentially lethal shock from a live wire or malfunctioning equipment.

The critical distinction is that not all "electrical" safety shoes are the same. The right shoe depends entirely on whether you need to protect the worker from a high-voltage shock or protect sensitive equipment from static discharge.

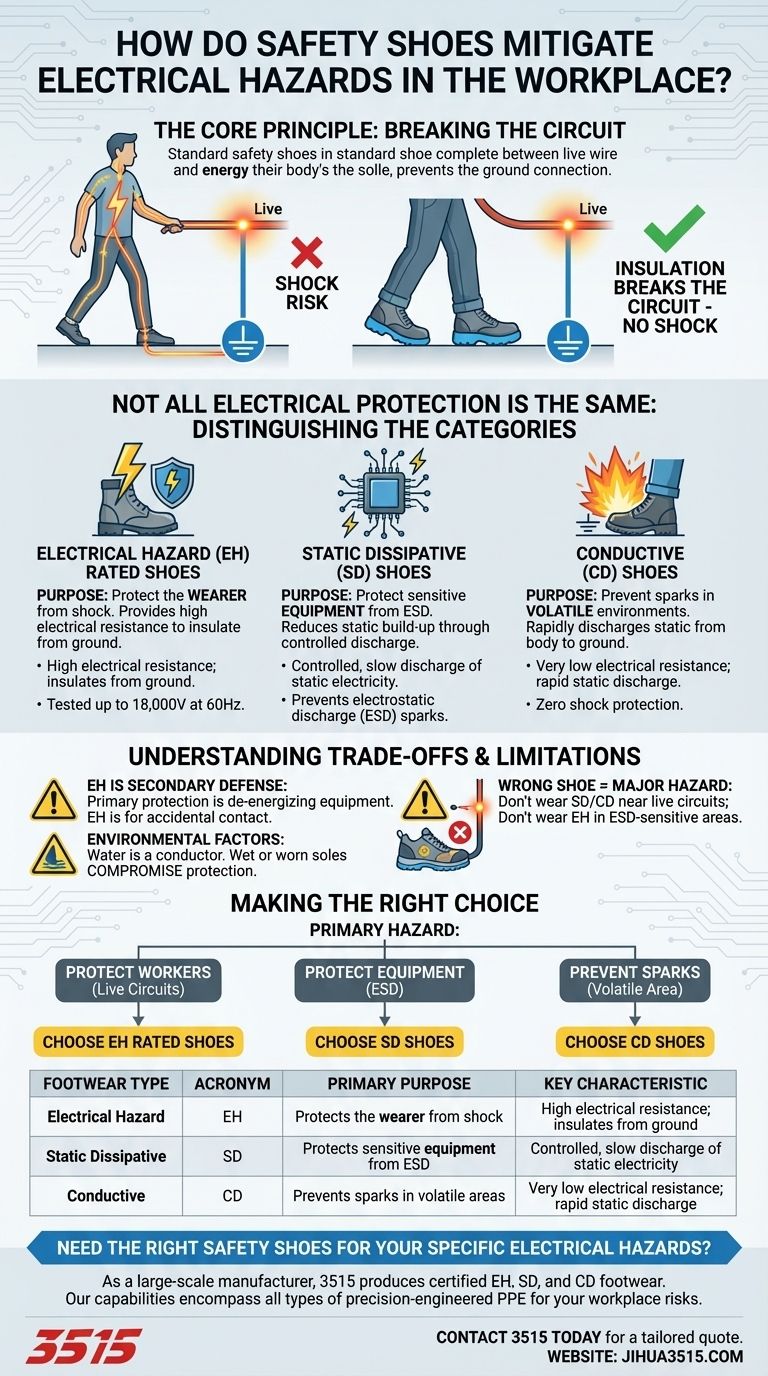

The Core Principle: Breaking the Circuit

To understand how these shoes work, you first have to understand how an electrical shock happens. It’s not just about touching a live wire; it's about your body completing an electrical circuit.

How Electrical Shock Occurs

An electric shock requires a complete path for electricity to flow. Often, this happens when a person makes contact with an energized source while also being in contact with the ground. Their body becomes the conductor that completes the circuit, allowing electricity to pass through them.

The Role of Insulation

Electrical Hazard (EH) rated safety shoes are designed to break this circuit. The outsoles are made from materials like rubber or specific leather compounds that do not conduct electricity.

This insulating barrier effectively isolates you from the ground. If you accidentally step on or touch an energized object, the shoe's sole prevents the current from traveling through your body to find its path to the earth.

Not All Electrical Protection is the Same

The term "electrical safety shoe" can be misleading because it covers three distinct categories with fundamentally different purposes. Choosing the wrong one can be ineffective or even dangerous.

Electrical Hazard (EH) Rated Shoes

This is the most common type of protection and is designed solely to protect the wearer from shock. These shoes are built with non-conductive materials and are tested to withstand a specific voltage (e.g., 18,000 volts at 60 Hz for one minute) without significant current flow.

Their function is purely defensive, serving as a last line of defense against accidental contact with a live electrical source.

Static Dissipative (SD) Shoes

Static Dissipative shoes are designed to protect sensitive electronic equipment, not the wearer. They reduce the build-up of static electricity in your body by slowly and safely discharging it to the ground.

This prevents a sudden electrostatic discharge (ESD) spark that could destroy microchips or other delicate components. They contain materials that are more conductive than EH shoes but still offer some minor electrical resistance.

Conductive (CD) Shoes

Conductive footwear offers the least electrical resistance. Its purpose is to protect against the hazards of static electricity in highly volatile environments where a single spark could ignite flammable materials or explosives.

These shoes are designed to conduct static electricity from the body to the ground as quickly as possible, ensuring no static charge can accumulate. They offer zero protection from electrical shock.

Understanding the Trade-offs and Limitations

Relying on safety footwear without understanding its limits creates a false sense of security. These shoes are a critical tool, but they are not foolproof.

EH Shoes Are a Secondary Defense

Your primary protection should always be proper safety procedures, such as de-energizing and locking out equipment. EH-rated footwear is a secondary measure intended to protect against accidental or unforeseen contact.

Environmental Factors Matter

The insulating properties of any shoe can be compromised. Water is an excellent conductor of electricity, so a thoroughly wet EH-rated boot will offer significantly less protection. Likewise, excessive wear or punctures in the sole can negate its safety rating.

The Wrong Shoe Creates a Hazard

Wearing the wrong type of shoe for the job is a major risk. If you wear SD or CD footwear while working near live circuits, you are providing electricity with an easy path to ground through your body. Conversely, wearing EH-rated shoes in an ESD-sensitive environment can allow static to build up, risking damage to equipment.

Making the Right Choice for Your Hazard

Selecting the correct footwear requires a clear understanding of the primary hazard in your specific workplace.

- If your primary focus is protecting workers from live circuits: You need Electrical Hazard (EH) rated footwear to insulate them from the ground.

- If your primary focus is protecting sensitive electronic components: You need Static Dissipative (SD) footwear to safely discharge static build-up from the body.

- If your primary focus is preventing sparks in a volatile environment: You need Conductive (CD) footwear for the most rapid discharge of static electricity.

Choosing the correct, certified safety shoe transforms it from simple PPE into a precision instrument designed for your specific work environment.

Summary Table:

| Footwear Type | Acronym | Primary Purpose | Key Characteristic |

|---|---|---|---|

| Electrical Hazard | EH | Protects the wearer from shock | High electrical resistance; insulates from ground |

| Static Dissipative | SD | Protects sensitive equipment from ESD | Controlled, slow discharge of static electricity |

| Conductive | CD | Prevents sparks in volatile areas | Very low electrical resistance; rapid static discharge |

Need the right safety shoes for your specific electrical hazards?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified EH, SD, and CD footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, ensuring you get precision-engineered PPE that matches your exact workplace risks.

Contact 3515 today to discuss your requirements and get a quote tailored to your needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Premium Sport Style Safety Boots for Bulk Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- What toe options are available for oil-resistant safety boots? Find the Right Fit for Your Job

- Why are piezoelectric ceramic plates commonly integrated into smart shoes? Powering the Future of Obstacle Avoidance

- How do optical motion capture systems and skin markers function in safety footwear walking experiments? Boost Gait Accuracy

- How do professional-grade safety shoes provide comprehensive protection for welders? Master Industrial Safety Standards

- How do arch area, toe position, and instep height influence safety shoe insole selection? Optimize Comfort & Stability with Data-Driven Choices

- Are motorcycle boots sold in Canada and the USA required to have CE certification? Understanding North American Safety Standards

- Why must micro-friction control be considered in the technical design of diabetic footwear? Prevent Ulcers & Shear

- Why is the use of electrical insulating shoes and gloves essential for industrial printing? Secure Your Safety Barrier