Ultimately, no. A boot not originally constructed with a dedicated waterproof membrane cannot be made fully and reliably waterproof. While you can significantly enhance its water resistance with topical treatments like waxes and sprays, these serve as a temporary external barrier. True waterproofing is built into the boot's core design, typically as an internal, impenetrable liner.

The critical distinction is between enhancing a material's surface to repel water and having an internal, structural barrier that blocks it entirely. While treatments are essential for maintenance, they cannot replicate the guaranteed protection of a boot designed from the ground up to be waterproof.

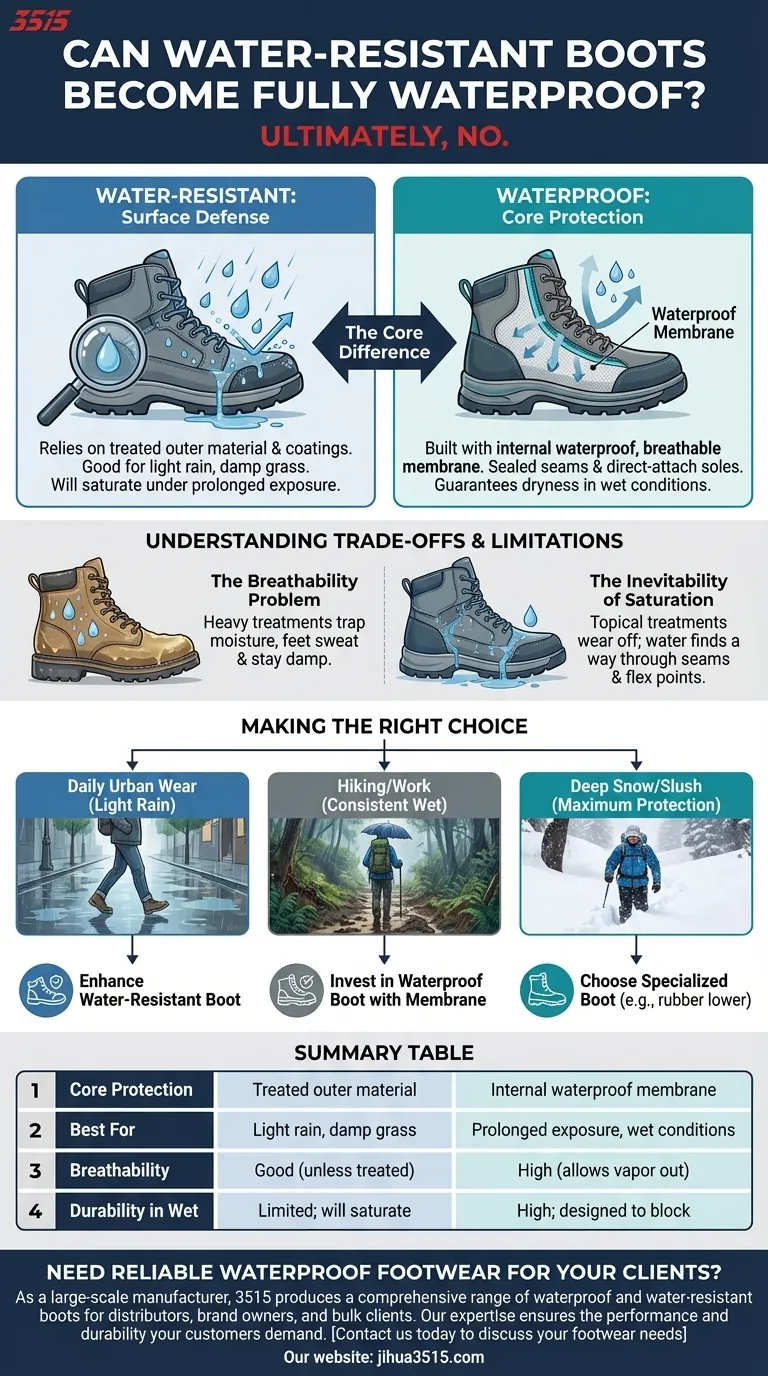

The Core Difference: Resistance vs. Proof

Understanding the terminology is the first step. These terms are not interchangeable; they describe fundamentally different levels of protection determined by a boot's construction.

What "Water-Resistant" Really Means

A water-resistant boot relies on the properties of its outer material, usually leather or a tightly woven synthetic fabric, to shed water. Often, these materials are treated with a coating that causes water to bead up and roll off.

This level of protection is sufficient for light, intermittent exposure like walking through damp grass or a brief shower. However, under sustained pressure or prolonged exposure, water will eventually saturate the material and seep through.

The Anatomy of a Truly Waterproof Boot

A genuinely waterproof boot has a secret weapon: an internal waterproof, breathable membrane. This is a sock-like liner, or "bootie," that sits between the outer material and the inner lining of the boot.

This membrane is a physical barrier with microscopic pores large enough to let water vapor (sweat) out but too small for liquid water droplets to get in. This is the component that does the real work of keeping your feet dry.

Construction is Key

Beyond the membrane, a boot's overall construction dictates its ability to keep water out. Weak points like seams and the point where the sole attaches to the upper are common areas for leaks.

Waterproof boots use sealed seams or waterproof stitching. The method of sole attachment—such as a sealed direct-attach sole versus a stitched Goodyear welt—also plays a crucial role in preventing water intrusion from below.

Understanding the Trade-offs and Limitations

Attempting to "upgrade" a water-resistant boot to be fully waterproof comes with significant compromises and will never provide guaranteed protection.

The Breathability Problem

The most common method for enhancing water resistance is applying heavy coats of wax or oil. While this can effectively seal the leather's pores and seams, it also traps moisture inside.

This severely reduces the boot's breathability. Your feet will sweat, and that moisture will have nowhere to go, leaving your socks damp and clammy. In many scenarios, wet feet from sweat can be just as uncomfortable and problematic as wet feet from rain.

The Inevitability of Saturation

Topical treatments are only a surface-level defense. They are subject to wear and tear, especially at flex points around the ankle and toes.

In conditions of prolonged exposure—like a long hike in steady rain or standing in a puddle—water will eventually find a way through the treated material and unsealed seams. A surface treatment cannot compete with a dedicated internal membrane.

Making the Right Choice for Your Needs

Instead of trying to make a boot do something it wasn't designed for, align your boot's capabilities with your intended use.

- If your primary focus is daily wear in urban areas with light rain: Enhancing a quality water-resistant leather boot with regular conditioning is often a perfect solution.

- If your primary focus is hiking or working in consistently wet conditions: Do not compromise; invest in a boot with an integrated waterproof membrane for reliable protection.

- If your primary focus is navigating deep snow, slush, or standing water: Choose a boot designed for maximum protection, such as a two-piece design with a burly rubber lower section.

Understanding your boot's fundamental design is the key to guaranteeing dry and comfortable feet for any task.

Summary Table:

| Feature | Water-Resistant Boot | Waterproof Boot |

|---|---|---|

| Core Protection | Treated outer material | Internal waterproof membrane |

| Best For | Light rain, damp grass | Prolonged exposure, wet conditions |

| Breathability | Good (unless heavily treated) | High (membrane allows vapor out) |

| Durability in Wet Conditions | Limited; will saturate | High; designed to block water |

Need reliable waterproof footwear for your clients?

As a large-scale manufacturer, 3515 produces a comprehensive range of waterproof and water-resistant boots for distributors, brand owners, and bulk clients. Our expertise in boot construction—including sealed seams and integrated membranes—ensures the performance and durability your customers demand.

Contact us today to discuss your footwear needs and explore our production capabilities.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

People Also Ask

- What technical challenge does the Bi-LSTM address in fall-detection? Enhancing Temporal Accuracy in Motion Sensing

- How does a mold temperature control system improve the dimensional accuracy of precision injection-molded parts?

- What technical advantages do customized functional insoles offer? Precision 3D Carving vs. Generic Insoles

- Why is EVA used with carbon fiber plates in footwear? Balancing Rigidity and Comfort for Peak Performance

- How are surface electromyography (EMG) sensors utilized to evaluate the impact of footwear materials on muscle fatigue? Uncover Objective Insights for Optimal Design

- How are industrial-grade three-dimensional force plates used in footwear evaluation? Master Gait & Shock Analysis

- Why is medical grade footwear preferred for diabetic ulcer prevention? Engineered Solutions for Foot Health

- What is the core function of the ASTM D 5034 Grab Test for auxetic PPE? Ensure Ultimate Structural Integrity