The 1960s marked the foundational era for the brand's reputation, defined by the introduction of performance fabrics that prioritized sheer physical resilience. During this decade, the brand released materials that became their hallmark, specifically engineered to meet the rigorous demands of industrial use rather than aesthetic appeal.

The brand's innovation in the 1960s focused entirely on industrial-strength durability. By prioritizing high abrasion resistance and tear strength, they secured a foothold in the workwear sector that established their technical identity.

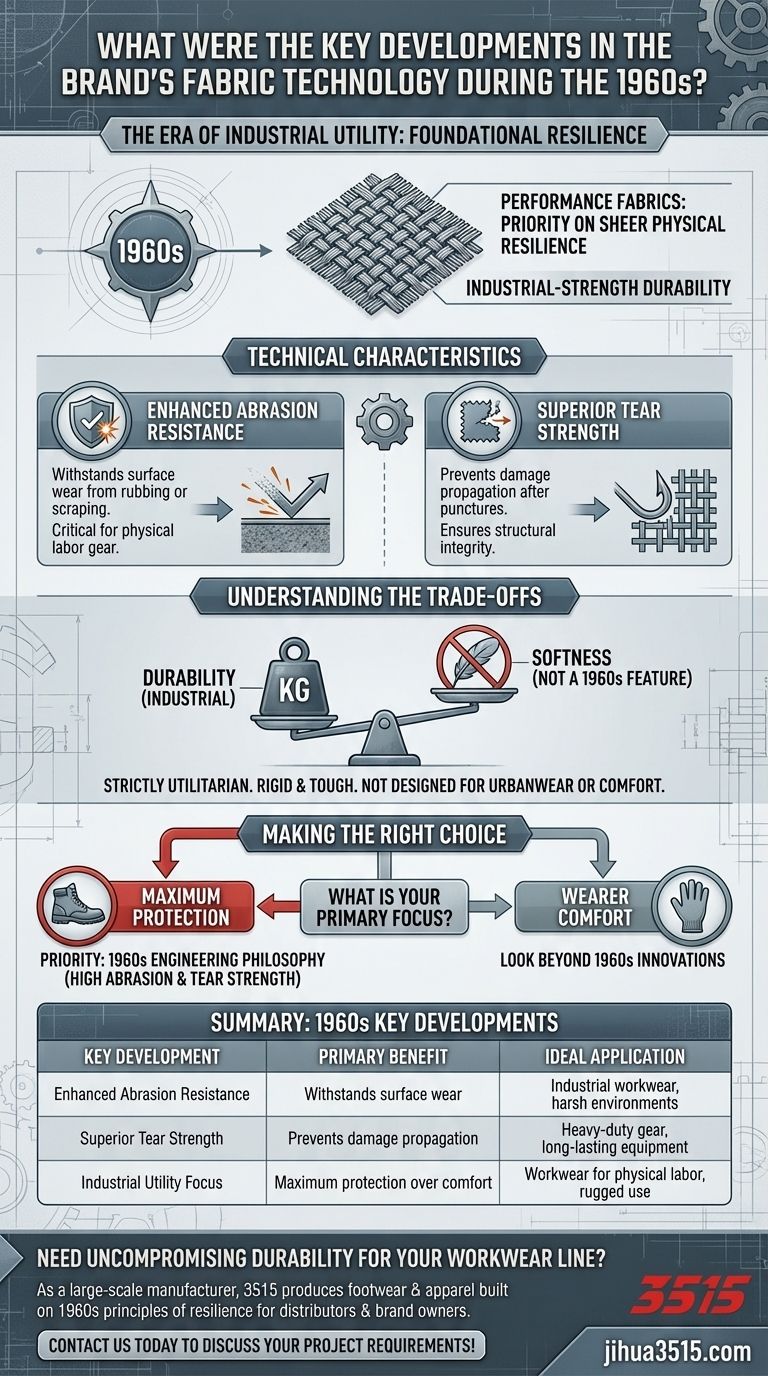

The Era of Industrial Utility

Establishing the Standard

In the 1960s, the brand moved beyond standard textiles to introduce durable performance fabrics. This was not an incremental update but a shift toward specialized engineering.

These materials laid the groundwork for the brand's long-term legacy. They were designed to function in environments where failure was not an option.

Immediate Industry Adoption

The market response was swift, particularly among workwear designers.

Professionals in this sector quickly recognized the practical value of these new materials. The adoption was driven by necessity, as standard fabrics of the time could not match this new level of performance.

Technical Characteristics

Enhanced Abrasion Resistance

The primary technical breakthrough of this era was the fabric's ability to withstand surface wear.

Abrasion resistance allows a material to resist mechanical action like rubbing or scraping. This feature was critical for gear used in physical labor or harsh terrain.

Superior Tear Strength

Beyond surface wear, the structural integrity of the weave was paramount.

The brand's 1960s technology offered significantly enhanced tear strength. This ensured that once the fabric was punctured or snagged, the damage would not easily propagate, extending the lifespan of the garment or gear.

Understanding the Trade-offs

Durability vs. Softness

It is important to understand the limitations of the 1960s technology compared to modern standards or later iterations.

While these fabrics were exceptionally tough, they lacked the tactile comfort introduced in later decades. The softness found in the brand's 1970s releases (such as the 500d Plus) was not a feature of the 1960s lineup.

Application Specificity

Because of this rigidity, the 1960s fabrics were strictly utilitarian.

They were not designed for the "urbanwear" or upholstery markets that the brand would eventually enter. This era was dedicated exclusively to heavy-duty performance where protection outweighed comfort.

Making the Right Choice for Your Goal

When evaluating the lineage of performance fabrics, distinguishing between these eras helps you select the right material for your project.

- If your primary focus is maximum protection: Prioritize the engineering philosophy of the 1960s, which centers on high abrasion resistance and tear strength for workwear environments.

- If your primary focus is wearer comfort: Recognize that the 1960s innovations were rigid; you should look toward the developments of the 1970s and beyond for softer, more pliable options.

The 1960s defined the brand's legacy as the premier provider of uncompromising, industrial-grade protection.

Summary Table:

| Key Development | Primary Benefit | Ideal Application |

|---|---|---|

| Enhanced Abrasion Resistance | Withstands surface wear from rubbing/scraping | Industrial workwear, harsh environments |

| Superior Tear Strength | Prevents damage propagation after punctures | Heavy-duty gear, long-lasting equipment |

| Industrial Utility Focus | Maximum protection over comfort | Workwear for physical labor, rugged use |

Need Uncompromising Durability for Your Workwear Line?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear and apparel for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of industrial-grade shoes, boots, and gear built on the same principles of durability and resilience pioneered in the 1960s. Let us help you develop products that meet the highest standards of abrasion resistance and tear strength. Contact us today to discuss your project requirements!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

People Also Ask

- How can plantar warts develop, and why is indoor footwear recommended? Protect Your Feet from Pain and Infection

- What role do footwear materials like EVA and Polyurethane play? Engineering Stability & Reducing Muscle Fatigue

- Why are dust protection consumables and ventilation equipment necessary in footwear sanding? Ensure Workplace Safety

- What is the largest venomous snake in South America? The Bushmaster's Formidable Threat

- What is the purpose of utilizing a circular rub fastness apparatus? Ensure Durable Color for High-Performance Footwear

- What are the technical advantages of immediate customized orthopedic insoles? Real-Time Diabetic Foot Care Solutions

- What is the Overall Stability Index (OSI) in Footwear Research? Achieve Superior Balance & Safety

- What makes textiles versatile for footwear design? Unlock the 5 Pillars of Material Engineering