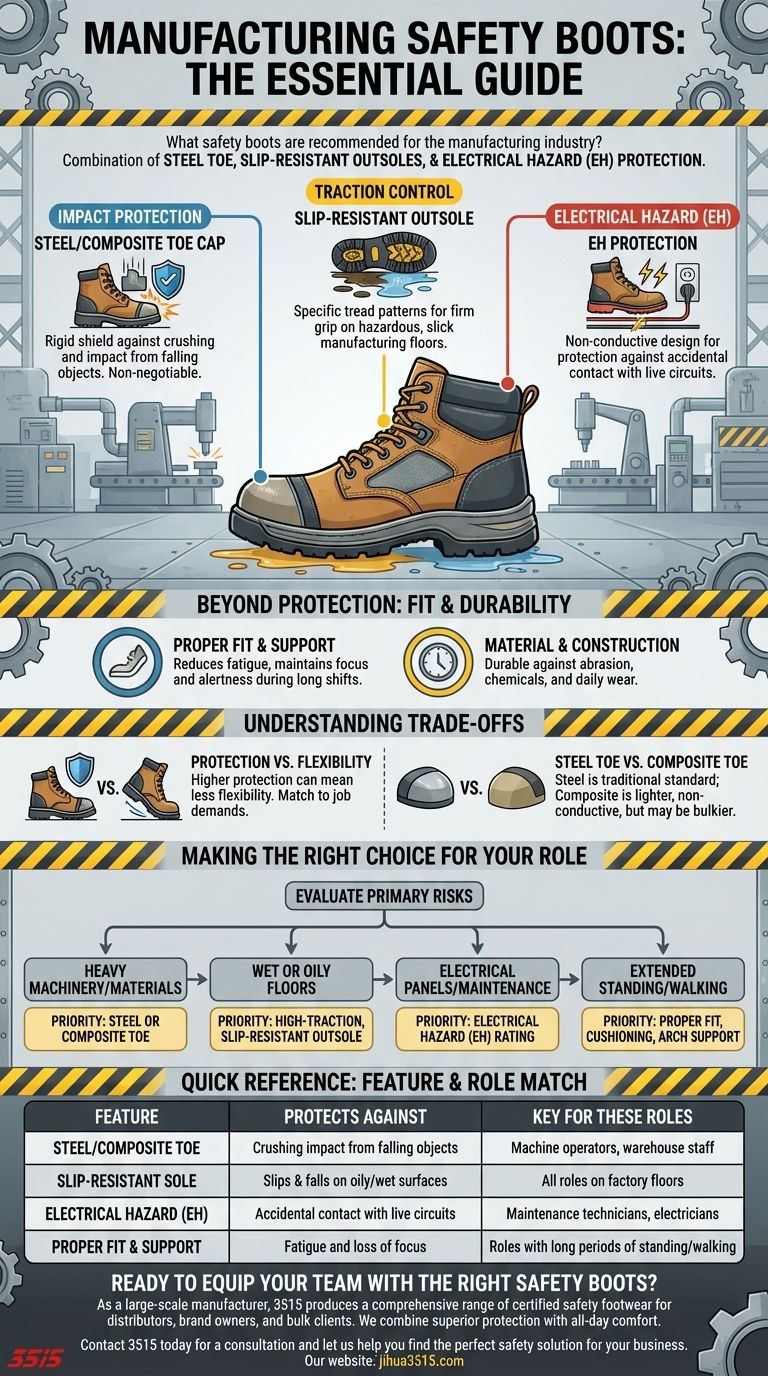

For the manufacturing industry, the best safety boots are those that provide a combination of a protective steel toe, slip-resistant outsoles, and electrical hazard (EH) protection. These features directly counter the most significant and frequent risks encountered in manufacturing environments, from falling objects and slick surfaces to accidental electrical contact.

Choosing the right safety boot isn't about finding a single "best" model, but about methodically matching the boot's protective features to the specific, daily hazards of your manufacturing role. The right boot for an assembly line worker may be insufficient for a maintenance technician.

Deconstructing the Essential Safety Features

To make an informed decision, you must understand the function behind each core component of a proper manufacturing safety boot. Each feature is designed to mitigate a specific, common workplace hazard.

Impact Protection: The Non-Negotiable Steel Toe

The most recognized feature of a safety boot is its protective toe cap. In manufacturing, this is non-negotiable.

Factories and industrial sites are dynamic environments with heavy machinery, moving parts, and the constant risk of falling tools or materials. A steel-toed boot provides a rigid shield that protects your feet from severe crushing and impact injuries.

Traction Control: Slip-Resistant Outsoles

Slips, trips, and falls are among the most common causes of workplace injury. Manufacturing floors can easily become hazardous.

Spills from lubricants, coolants, or cleaning agents can create slick surfaces. A boot with a certified slip-resistant sole is designed with specific tread patterns and rubber compounds to maintain a firm grip and prevent these accidents.

Electrical Hazard (EH) Protection

For anyone working near electrical equipment, control panels, or wiring, this feature is critical. It can be a literal lifesaver.

Electrical Hazard (EH) rated boots are constructed with non-conductive soles and heels. This design provides a secondary source of protection against electrocution from accidental contact with a live electrical circuit.

Beyond Protection: The Role of Fit and Durability

While safety features are paramount, they are ineffective if the boot is so uncomfortable or poorly made that it isn't worn properly.

The Importance of Proper Fit and Support

You will spend hours standing, walking, and working in these boots. A poor fit doesn't just cause discomfort; it causes fatigue.

Fatigue leads to a loss of focus, which significantly increases the risk of an accident. Proper arch support and cushioning are essential for maintaining comfort, productivity, and—most importantly—alertness throughout a long shift.

Material and Construction

Manufacturing environments are demanding. Your boots must be durable enough to withstand abrasion, potential chemical exposure, and daily wear and tear.

Look for high-quality materials and sturdy construction to ensure the boot not only lasts but also maintains its structural and protective integrity over time.

Understanding the Trade-offs

Selecting the perfect boot always involves balancing competing priorities. Understanding these trade-offs is key to choosing wisely.

Protection Level vs. Flexibility

As a general rule, boots that offer higher levels of protection are often heavier and more rigid. This can sometimes limit mobility and flexibility.

Consider the specific demands of your job. A worker who needs to frequently crouch or climb may require a more flexible boot than a forklift operator, even if their impact protection needs are similar.

Steel Toe vs. Composite Toe

While steel is the traditional standard, modern composite toes (made from materials like Kevlar, carbon fiber, or plastic) are a common alternative.

Composite toes are lighter than steel and do not conduct heat, cold, or electricity. However, they can sometimes appear bulkier to achieve the same safety rating as steel.

Making the Right Choice for Your Role

To select the ideal boot, evaluate the primary risks of your specific job.

- If you work around heavy machinery or materials: Your absolute priority must be a certified steel or composite toe for maximum impact protection.

- If your environment has wet or oily floors: A high-traction, slip-resistant outsole is your most critical feature for preventing falls.

- If you are a maintenance technician or work near electrical panels: Ensure your boots have a clear Electrical Hazard (EH) rating as a non-negotiable line of defense.

- If you stand or walk for extended shifts: Do not compromise on a proper fit, cushioning, and arch support to maintain focus and prevent fatigue-related injuries.

Ultimately, the right safety boot is an essential piece of personal protective equipment that empowers you to perform your job safely and effectively.

Summary Table:

| Feature | Protects Against | Key for These Roles |

|---|---|---|

| Steel/Composite Toe | Crushing impact from falling objects | Machine operators, warehouse staff |

| Slip-Resistant Sole | Slips & falls on oily/wet surfaces | All roles on factory floors |

| Electrical Hazard (EH) | Accidental contact with live circuits | Maintenance technicians, electricians |

| Proper Fit & Support | Fatigue and loss of focus | Roles with long periods of standing/walking |

Ready to equip your team with the right safety boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. We combine superior protection with all-day comfort, ensuring your workforce is safe, productive, and supported.

Our production capabilities encompass all types of safety shoes and boots tailored to the demands of the manufacturing industry.

Contact 3515 today for a consultation and let us help you find the perfect safety solution for your business.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Premium Sport Style Safety Boots for Bulk Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- What are heavy duty work boots designed for? Maximum Protection for Hazardous Work Environments

- Why are safety boots with steel toes mandatory for logging? Ultimate Protection Against Heavy Impact Hazards

- Why do operations involving heavy fruit bunches and 'gancu' require anti-smash and anti-puncture safety boots?

- What boots do they wear on oil rigs? Essential Safety Footwear for Harsh Conditions

- What are the primary protective roles of safety shoes for mosquito control? Safeguard Workers from Chemical & Field Risks