For a material to be both durable and breathable, you must look at specific, often engineered, solutions. The top contenders are full-grain leather, high-performance synthetic meshes often reinforced with stronger fibers, and technical blended fabrics designed for specific performance goals.

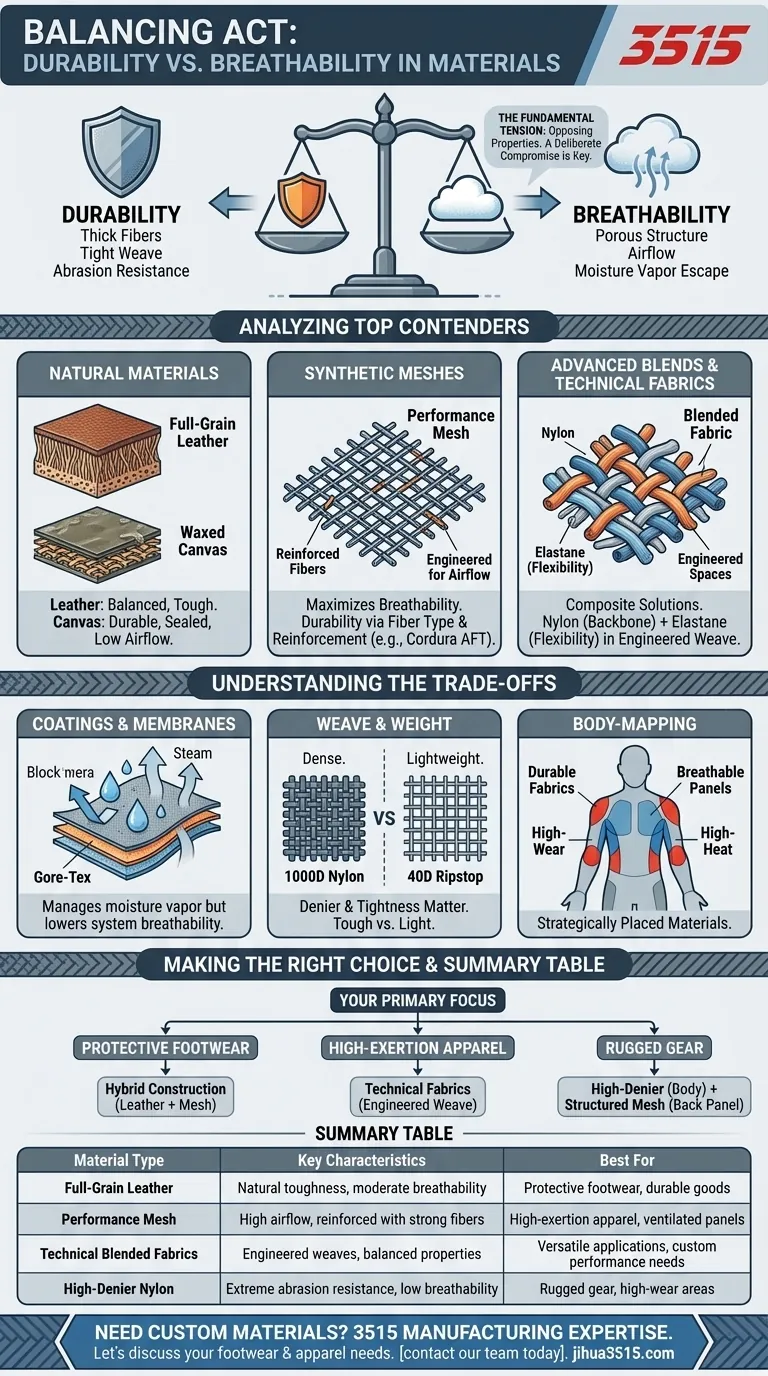

The core challenge is that durability and breathability are fundamentally opposing properties. True durability often requires dense, tightly woven materials that block airflow, while breathability demands a porous structure that can be inherently weaker. The ideal material is therefore not a single substance, but a deliberate compromise engineered for a specific use case.

The Fundamental Tension: Durability vs. Breathability

The relationship between these two characteristics is the central trade-off in performance materials. Understanding this principle is key to making an informed choice.

Why Durability Fights Breathability

Durability, especially abrasion resistance, comes from using thick, strong fibers in a tight, dense weave. This creates a formidable physical barrier, but it also naturally closes off the pores needed for air and moisture vapor to escape.

How Breathability Creates Weakness

Breathability is achieved by creating space within a fabric's structure. This can be done through a loose weave, thinner fibers, or an open-knit construction like mesh. These openings, however, create points of failure and expose the individual fibers to more wear and tear.

Analyzing the Top Contenders

No single material wins in every category. The best choice depends entirely on the application, from footwear to apparel to gear.

Natural Materials: Leather and Canvas

Full-grain leather is a classic example of a balanced material. Its natural fibrous structure is incredibly tough and abrasion-resistant, yet it contains microscopic pores that allow for a moderate degree of breathability.

Waxed canvas is an example of prioritizing durability at the expense of breathability. The canvas itself is moderately breathable, but the wax coating that provides immense water resistance and durability effectively seals it, eliminating airflow.

Synthetic Meshes: Engineered for Airflow

Modern performance mesh is designed from the ground up for maximum breathability. Its durability comes not from the mesh itself, but from the type of fiber used and the inclusion of a reinforcing grid.

Materials like Cordura AFT (Air Flow Technology) Mesh use high-tenacity nylon fibers, known for their exceptional strength, to create a mesh that is far more resistant to tearing and abrasion than standard polyester mesh.

Advanced Blends and Technical Fabrics

This is where most modern innovation occurs. Manufacturers create fabrics that are not one thing, but a composite of several.

A common strategy is to blend a durable fiber like nylon with a flexible fiber like elastane in a specific weave. The nylon provides the rugged backbone, while the weave itself is engineered to allow for a calculated amount of air permeability.

Understanding the Trade-offs

Simply choosing a material by name is not enough. How it's constructed and treated has a massive impact on its final performance.

The Impact of Coatings and Membranes

Waterproof-breathable membranes like Gore-Tex are a prime example of managing this trade-off. The membrane itself allows moisture vapor to pass through but is fragile. It is laminated to a durable face fabric for protection, and the entire system's breathability is lower than that of a simple, non-membrane fabric.

Weave and Weight Matter Immensely

You cannot judge a material like "nylon" as a monolith. The fiber thickness, measured in denier, and the tightness of the weave are critical. A 1000D (denier) ballistic nylon is incredibly tough but feels like plastic, while a 40D ripstop nylon is lightweight and more breathable but far less durable.

High-Wear vs. High-Breathability Zones

The most sophisticated designs don't use a single material. They use a technique called body-mapping, placing highly durable, less-breathable fabrics (like Cordura) on high-wear areas like shoulders and elbows, while using lighter, breathable panels in high-heat zones like the back and underarms.

Making the Right Choice for Your Application

Your final selection should be guided by your primary requirement.

- If your primary focus is protective footwear: Seek a hybrid construction featuring durable leather or synthetic sections for structure, combined with strategically placed reinforced mesh panels for ventilation.

- If your primary focus is high-exertion apparel: Prioritize technical synthetic fabrics where the specific weave is engineered for air permeability, even if it sacrifices a small amount of ultimate abrasion resistance.

- If your primary focus is rugged gear like a backpack: Choose high-denier fabrics like Cordura for the main body to ensure durability, but demand a back panel that uses a structured, open-cell mesh to allow for critical airflow.

Choosing the right material means understanding that you are always managing a compromise between conflicting, but essential, properties.

Summary Table:

| Material Type | Key Characteristics | Best For |

|---|---|---|

| Full-Grain Leather | Natural toughness, moderate breathability | Protective footwear, durable goods |

| Performance Mesh (e.g., Cordura AFT) | High airflow, reinforced with strong fibers | High-exertion apparel, ventilated panels |

| Technical Blended Fabrics | Engineered weaves, balanced properties | Versatile applications, custom performance needs |

| High-Denier Nylon (e.g., Cordura) | Extreme abrasion resistance, low breathability | Rugged gear, high-wear areas |

Need custom materials for your footwear or apparel line?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our expertise in material selection and production ensures your products achieve the perfect balance of durability and breathability. Let’s discuss your specific needs — contact our team today to get started!

Visual Guide

Related Products

- Wholesale Modern Comfort Shoes with Dial Closure for Private Label & Bulk Orders

- Lightweight Breathable Sneakers with Wet-Traction Grip for Wholesale & Private Label

- Men's Breathable Perforated Loafers Wholesale & OEM Manufacturing

- Wholesale Breathable Perforated Slip-On Loafers Custom Manufacturing

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

People Also Ask

- What features should teachers look for in work shoes? Find All-Day Comfort & Support

- What are some recommendations for comfortable women's work shoes? Find the Perfect Fit for All-Day Support

- What features enhance the comfort of the best formal dress shoes? A Guide to All-Day Support

- What special requirements should work shoes for all-day wear meet? Key Features for All-Day Comfort & Safety

- What are the key features of shoes for flight attendants? Unlock All-Day Comfort & Professional Style