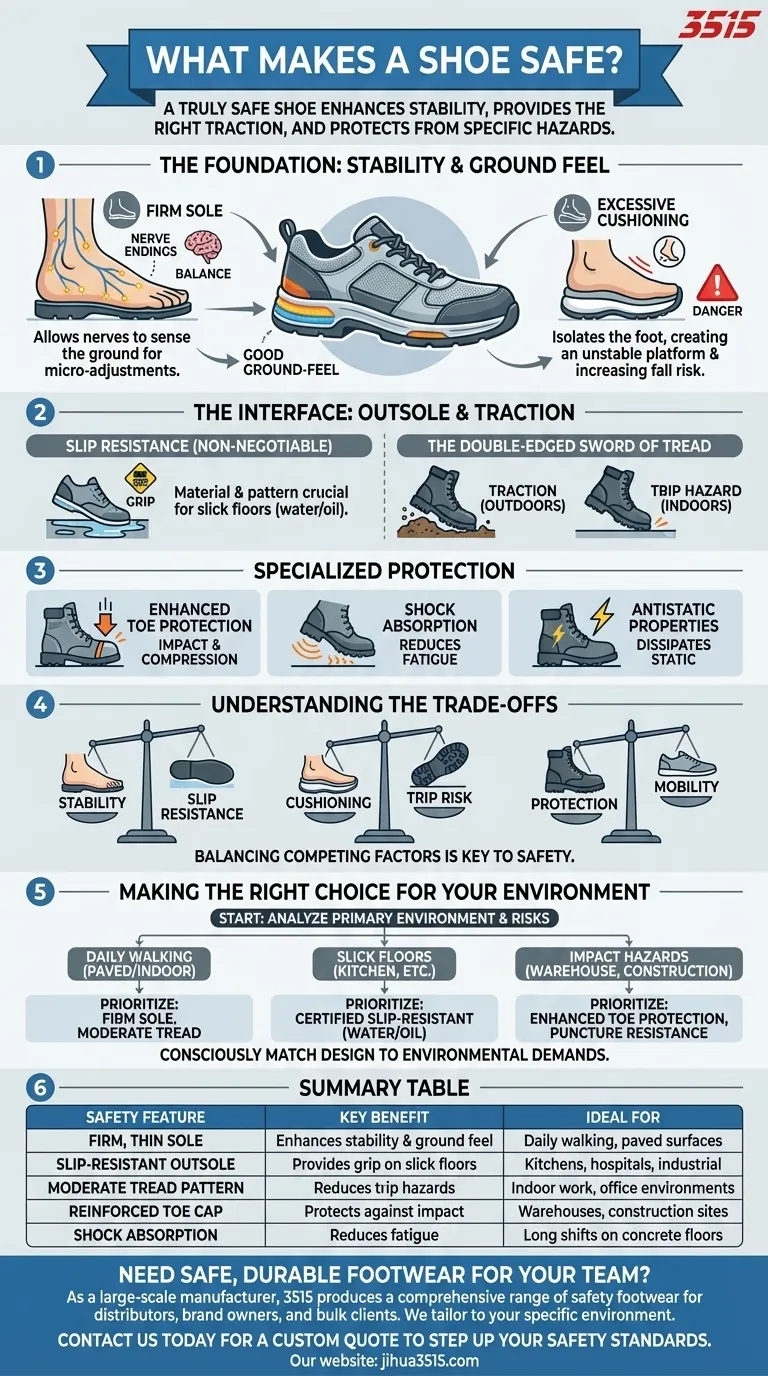

A truly safe shoe is one that enhances your stability, provides the right kind of traction for your environment, and protects your foot from specific, relevant hazards. Its core features are a firm, relatively thin sole for good ground-feel, a slip-resistant outsole, and a tread pattern that prevents trips rather than causing them.

The concept of a "safe" shoe is not universal; it is entirely dependent on the environment. The key is to understand that features offering safety in one context, like aggressive tread on a trail, can introduce new risks, like tripping, in another.

The Foundation: Stability and Ground Feel

A shoe's primary safety function is to create a stable base that works with your body's natural mechanics. This begins with the design of the sole and cushioning.

Why a Firm Sole is Critical

A firm and relatively thin sole allows the thousands of nerves in your feet to sense the ground. This feedback is essential for your brain to make the micro-adjustments necessary for balance and stability.

The Danger of Excessive Cushioning

While soft cushioning can feel comfortable, too much of it can be dangerous. It isolates the foot from the ground, creating an unstable platform that can increase the risk of ankle rolls and falls.

The Interface: Outsole and Traction

The outsole is where the shoe meets the world. Its design dictates how it will interact with different surfaces, which is a critical component of preventing slips and trips.

Slip Resistance is Non-Negotiable

The material and pattern of the outsole determine its slip resistance. For work environments, resistance to water and oil is often necessary to maintain grip on slick floors.

The Double-Edged Sword of Tread

Tread creates friction, but its design is a careful balance. A deep, aggressive tread is excellent for loose surfaces like dirt or gravel. However, on smooth, flat floors, that same tread can catch and become a significant trip hazard.

Specialized Protection for Specific Hazards

For work or specialized activities, safety extends beyond stability and traction to include protection from direct threats.

Enhanced Toe Protection

Shoes with reinforced toe boxes, often made of steel or composite materials, protect the foot from falling objects and compression injuries common in industrial settings.

Shock Absorption and Antistatic Properties

Some environments require shoes that can safely dissipate static electricity to protect sensitive equipment. Others may prioritize outsoles that absorb shock to reduce fatigue and strain from standing on hard surfaces for long periods.

Understanding the Trade-offs

Choosing a safe shoe always involves balancing competing factors. What makes a shoe safe for a construction worker is fundamentally different from what makes one safe for a hospital nurse.

Stability vs. Cushioning

The primary trade-off is between the immediate comfort of soft cushioning and the long-term safety of a stable, firm sole. For safety, stability should almost always be the priority.

Slip Resistance vs. Trip Risk

You must match the outsole to the surface. A highly-textured, high-traction outsole designed for outdoor trails can be a liability indoors, where a lower-profile, slip-resistant design is safer and more effective.

Protection vs. Mobility

Features like steel toes add significant weight and can reduce a shoe's flexibility. While essential for certain jobs, this added bulk can impede agility and may be unnecessary and cumbersome in other contexts.

Making the Right Choice for Your Environment

To select the safest shoe, start by analyzing your primary environment and its specific risks.

- If your primary focus is daily walking on paved or indoor surfaces: Prioritize a shoe with a firm, stable sole and a moderate tread that will not catch or trip you on flat ground.

- If your primary focus is working in an environment with slick floors (e.g., a kitchen): Look for certified slip-resistant shoes, paying close attention to their ability to handle water and oil.

- If your primary focus is working where impact hazards exist (e.g., a warehouse or construction site): Your non-negotiable features are enhanced toe protection and a sole that can resist punctures.

Ultimately, choosing a safe shoe is about consciously matching its design features to the demands of your environment.

Summary Table:

| Safety Feature | Key Benefit | Ideal For |

|---|---|---|

| Firm, Thin Sole | Enhances stability and ground feel for better balance | Daily walking, paved surfaces |

| Slip-Resistant Outsole | Provides grip on slick, wet, or oily floors | Kitchens, hospitals, industrial settings |

| Moderate Tread Pattern | Reduces trip hazards on flat surfaces | Indoor work, office environments |

| Reinforced Toe Cap | Protects against impact and compression injuries | Warehouses, construction sites |

| Shock Absorption | Reduces fatigue from standing on hard surfaces | Long shifts on concrete floors |

Need Safe, Durable Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Whether you need slip-resistant shoes for a restaurant chain or steel-toe boots for a construction crew, our production capabilities encompass all types of protective shoes and boots tailored to your specific environment.

Contact us today for a custom quote and let us help you step up your safety standards.

Visual Guide

Related Products

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Wholesale Leather Safety Boots with Customizable Protective Toe

People Also Ask

- Why are industrial safety shoes necessary for mining machinery maintenance? Protect Feet from Crushing and Punctures

- What are examples of protective footwear required in different workplaces? Ensure OSHA Compliance & Worker Safety

- How much weight can steel toes and composite toes handle? Both Protect Against 2,500 Pounds

- Why do landscapers need steel-toe boots? Essential Protection for a Hazardous Job

- What workplace factors should be considered when choosing between steel and safety toes? Ensure Optimal Foot Protection