In the world of safety footwear, the terms "non-skid" and "slip-resistant" are used interchangeably. There is no technical or regulatory difference between them. Both labels refer to footwear specifically engineered with features to provide superior grip, enhance stability, and prevent slips or falls on hazardous surfaces.

The critical distinction is not the marketing term used, but in the shoe's specific design features and how they match your unique work environment. True safety comes from understanding the technology, not just the label.

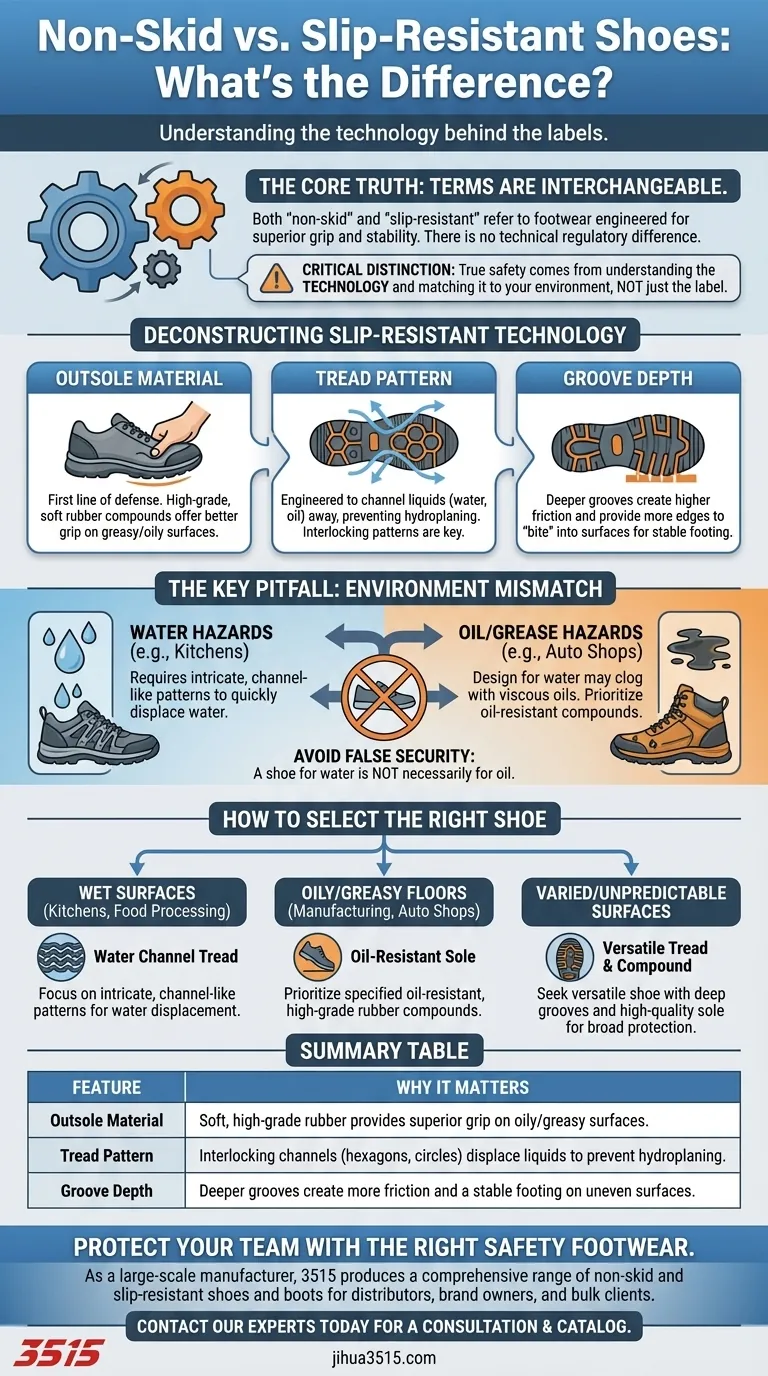

Deconstructing Slip-Resistant Technology

To make an informed choice, you must look past the name and understand the core components that provide genuine protection. The effectiveness of any slip-resistant shoe is determined by a combination of material science and engineering design.

The Role of Outsole Material

The compound used for the bottom of the shoe is the first line of defense. High-grade, soft rubber compounds offer a better grip, especially on greasy or oily surfaces, compared to harder, less pliable materials.

The Importance of Tread Pattern

The design of the tread is engineered to manage contaminants. Interlocking patterns, often hexagonal or circular, are designed to channel liquids like water and oil away from the point of contact between the shoe and the floor. This prevents a layer of liquid from forming, which is a primary cause of hydroplaning and slips.

The Function of Groove Depth

Deeper grooves in the outsole create higher friction. These deep channels provide more edges to "bite" into the walking surface, maximizing the contact area and providing a more stable footing, especially when surfaces are not perfectly smooth.

Understanding the Key Pitfall: Environment Mismatch

The most common mistake is assuming that any slip-resistant shoe is suitable for all conditions. This creates a false sense of security, which can be more dangerous than wearing standard footwear.

A Shoe for Water is Not a Shoe for Oil

The design features that make a shoe excellent on wet floors may not be effective on oily or greasy surfaces. A tread pattern optimized for channeling water may become clogged and slick when exposed to viscous oils, rendering it ineffective.

Always Match the Shoe to the Hazard

You must identify the primary slip hazards in your environment. Are you dealing with water in a commercial kitchen, oil in an automotive garage, or dust on a polished concrete floor? Each requires a different design emphasis.

Check the Manufacturer's Specifications

Look beyond the simple "slip-resistant" label. Reputable manufacturers will provide detailed specifications on the conditions their shoes are tested and rated for. This information is your most reliable guide to a shoe's true performance capabilities.

How to Select the Right Shoe for Your Goal

To ensure maximum safety, match the shoe's specific features to your primary workplace hazards.

- If your primary focus is wet surfaces (e.g., kitchens, food processing): Look for shoes with intricate, channel-like tread patterns designed to quickly and efficiently displace water.

- If your primary focus is oily or greasy floors (e.g., manufacturing, auto shops): Prioritize shoes made with a specified oil-resistant, high-grade rubber compound for the outsole.

- If you work on varied or unpredictable surfaces: Seek a versatile shoe with both deep, aggressive grooves for general friction and a high-quality sole material for broad protection.

Choosing the right footwear is an act of understanding your environment, not just reading a label.

Summary Table:

| Feature | Why It Matters for Slip Resistance |

|---|---|

| Outsole Material | Soft, high-grade rubber provides superior grip on oily/greasy surfaces. |

| Tread Pattern | Interlocking channels (hexagons, circles) displace liquids to prevent hydroplaning. |

| Groove Depth | Deeper grooves create more friction and a stable footing on uneven surfaces. |

Protect your team with the right safety footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of non-skid and slip-resistant shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear, engineered with the specific outsole compounds and tread patterns needed for kitchens, factories, auto shops, and more. Let us help you match the perfect shoe to your unique workplace hazards. Contact our experts today for a consultation and catalog.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- How do visual-guidance requirements for automated agricultural tasks dictate slip-resistance? Enhanced Safety Design

- What is the significance of slip resistance in work shoes? Essential Safety for High-Risk Environments

- How does the floor type affect slip-resistant shoe choice? Match Your Sole to Your Surface

- What materials are best for non-slip shoes? Achieve Superior Traction and Safety

- How are slip-resistant shoes certified for safety? Ensure Workplace Safety with Certified Footwear

- How do chef clogs differ from regular non-slip shoes? A Guide to Professional Kitchen Footwear

- How do men's work shoes ensure comfort during long work hours? An Engineer's Guide to All-Day Support

- What is the purpose of a digital surface profilometer in footwear testing? Master Surface Roughness & Slip Resistance