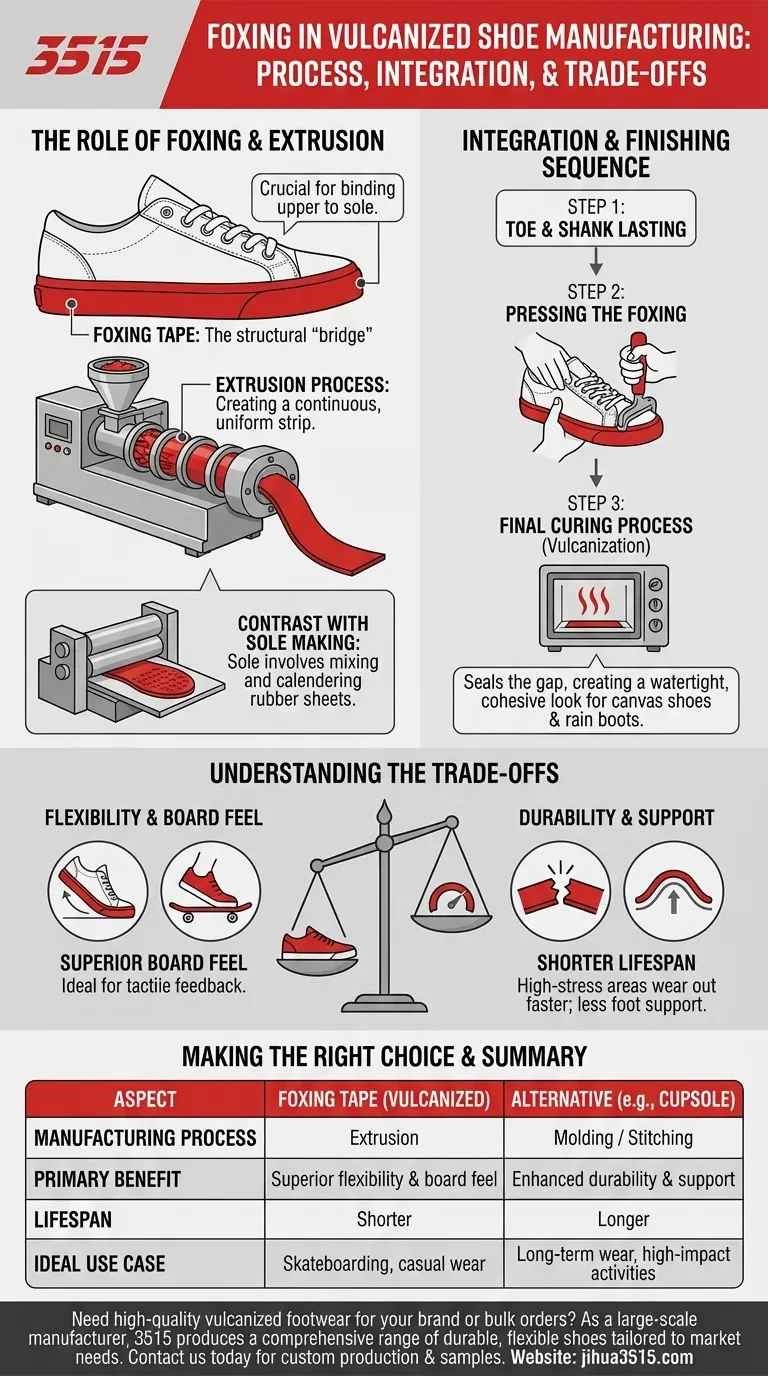

Foxing is manufactured primarily through a process called extrusion. Unlike the outsole, which is often molded or calendered, the foxing is created by forcing rubber material through a die to form a continuous, shaped strip. This strip serves as the critical sidewall that binds the upper of the shoe to the sole.

While the outsole provides traction and the upper provides fit, the foxing tape acts as the structural "bridge" in vulcanized construction. It is an extruded component applied during finishing to seal the shoe before the final curing process.

The Role of Foxing in Construction

The Extrusion Process

The creation of the foxing tape is distinct from the creation of the sole. Foxing is made via extrusion, a method that creates a long, continuous profile of rubber.

This allows for a uniform thickness and width, which is essential for wrapping around the curvature of the shoe without breaking or thinning unevenly.

Contrast with Sole Making

While foxing is extruded, the sole making process is more complex. The sole involves mixing rubber and calendering it into a sheet.

This sheet is then formed through hot-pressing and burnishing. The foxing is added later to join this pressed sole to the rest of the shoe.

Integration and Finishing

The Assembly Sequence

Foxing is applied during the shoe finishing stage. This stage includes several pressing steps: pressing the toe lasting, pressing the shank lasting, and pressing the foxing.

This manual or semi-automated application ensures the rubber strip adheres tightly to both the fabric upper (vamp) and the rubber outsole.

Creating the Final Bond

Once the insole is glued and the outsole and vamp are pressed, the foxing seals the gap between them.

This creates the watertight and cohesive look typical of canvas shoes and rain boots. The pressure applied during this stage is vital for ensuring the shoe survives the vulcanization oven without delaminating.

Understanding the Trade-offs

Durability and Lifespan

Because the foxing is a rubber strip bonded by heat and glue rather than stitching, there are limitations. Vulcanized shoes tend to wear out faster than stitched alternatives like cupsoles.

The foxing tape is a high-stress area; repeated flexing can eventually cause the rubber to crack or separate from the fabric upper.

Flexibility vs. Support

The use of foxing and vulcanized construction results in a shoe that is highly flexible and offers superior board feel. This is a massive benefit for activities requiring tactile feedback.

However, this construction provides less foot support compared to other methods. The foxing offers lateral containment, but it lacks the rigidity of a structured midsole or cupsole.

Making the Right Choice for Your Goal

Whether you choose a shoe constructed with foxing tape depends on your specific performance requirements.

- If your primary focus is flexibility and board feel: Choose vulcanized construction, as the extruded foxing allows for maximum tactile response and ease of movement.

- If your primary focus is long-term durability and arch support: Consider alternatives to standard vulcanized foxing, as these shoes typically wear out faster and offer less structural stability.

Understanding how foxing is extruded and applied helps you predict exactly how the shoe will perform under stress.

Summary Table:

| Aspect | Foxing Tape (Vulcanized) | Alternative (e.g., Cupsole) |

|---|---|---|

| Manufacturing Process | Extrusion | Molding / Stitching |

| Primary Benefit | Superior flexibility & board feel | Enhanced durability & support |

| Lifespan | Shorter (stress on bonded areas) | Longer (reinforced construction) |

| Ideal Use Case | Skateboarding, casual wear | Long-term wear, high-impact activities |

Need high-quality vulcanized footwear for your brand or bulk orders?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our expertise in extrusion and vulcanization processes ensures durable, flexible shoes tailored to your market needs.

Contact us today to discuss custom production, samples, and competitive pricing!

Visual Guide

Related Products

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

People Also Ask

- What types of skating are cupsole shoes best suited for? The Ultimate Choice for High-Impact Skating

- Why is the incorporation of wide shoe lasts essential in the design of court sports shoes for the elderly? Top Benefits

- Why is a full-wave bridge rectifier a necessary component in the circuit design of energy-harvesting smart shoes?

- What are the pros and cons of thick, cushioned soles versus thin soles? Find Your Perfect Fit

- Can sneakers be worn with suits in a business casual environment? Master the Modern Style

- How is the sole made for vulcanized shoes? Discover the High-Heat Bonding Process

- How do toe caps benefit skate shoes? Maximize Durability & Improve Trick Control

- How does the weight of a running shoe impact the endurance levels of long-distance runners? Optimize Your Running Economy