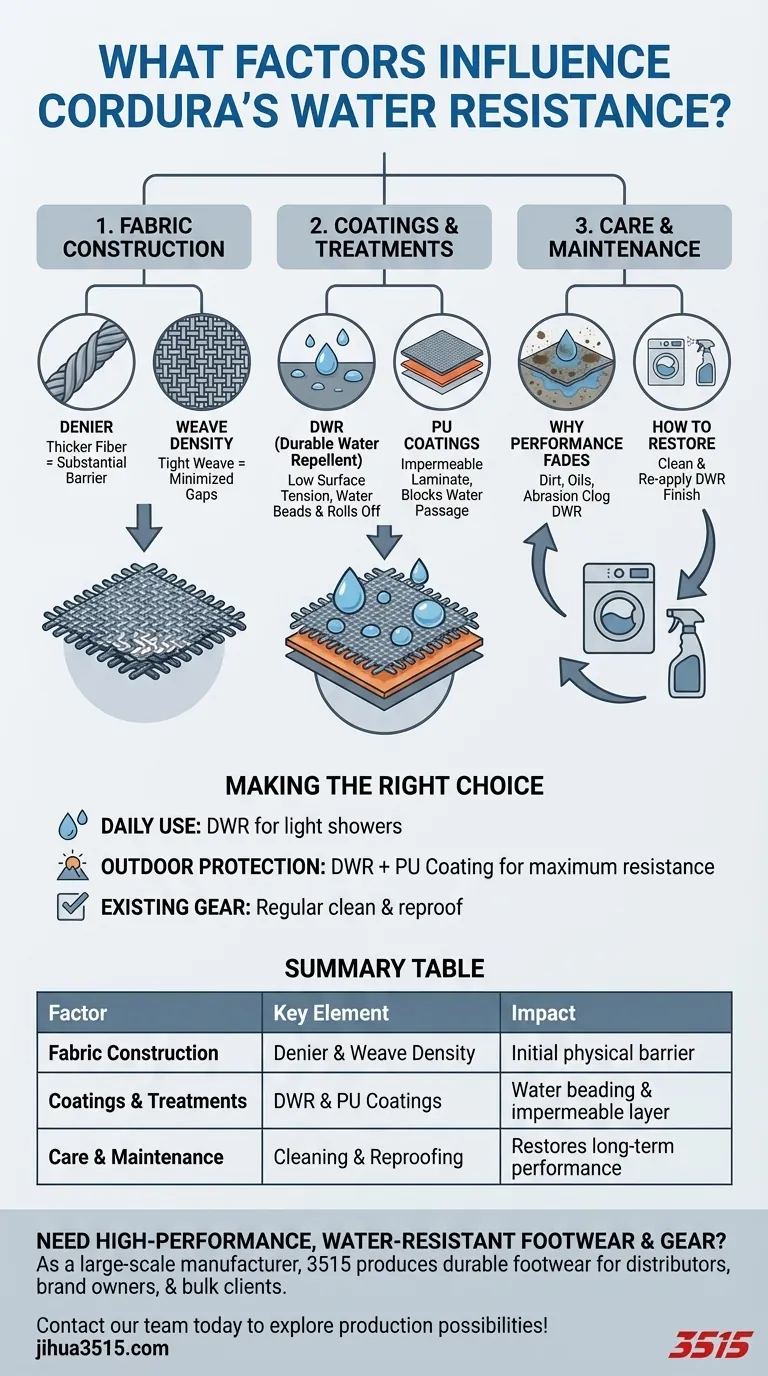

Three primary factors determine Cordura's level of water resistance: the inherent thickness and weave of the fabric itself, the application of specific coatings or treatments, and the long-term care and maintenance the material receives. Thicker, denser fabrics provide a better initial barrier, but chemical treatments like a Durable Water Repellent (DWR) finish are what cause water to bead up and roll off the surface.

Cordura is engineered to be highly water-resistant, but it is not inherently waterproof. Its true performance in wet conditions is a result of a system where the fabric's construction, added coatings, and proper maintenance all work together.

The Foundation: Fabric Construction

The physical structure of the Cordura fabric itself serves as the first line of defense against moisture. Two key properties define this initial level of resistance.

The Role of Denier

Denier is a unit of measurement for the thickness of a fiber. A higher denier number indicates a thicker, heavier, and generally more durable yarn.

This increased thickness contributes to water resistance by creating a more substantial physical barrier that water has difficulty penetrating quickly.

The Importance of Weave Density

Beyond thickness, the tightness of the weave is critical. Cordura fabrics are known for their dense weaves, which minimize the gaps between the yarns.

This tight construction makes it physically harder for water droplets to pass through the material, forcing them to sit on the surface instead of soaking in immediately.

The Critical Enhancement: Coatings and Treatments

While the fabric provides a solid base, specialized treatments are what elevate Cordura's performance from merely durable to truly water-resistant.

DWR (Durable Water Repellent)

A DWR coating is a chemical finish applied to the exterior of the fabric. It works by lowering the surface tension, causing water to form beads and roll off rather than being absorbed.

This is the most common treatment and is responsible for the visible effect of water beading on new gear. It is the primary defense against light precipitation.

Polyurethane (PU) Coatings

For a much higher level of water resistance, many Cordura products feature a polyurethane (PU) coating applied to the backside of the fabric.

This coating acts as a solid, impermeable laminate layer, effectively blocking water from passing through. A fabric with a quality PU coating is often considered waterproof for most practical applications, like in backpacks or luggage.

The Key to Longevity: Care and Maintenance

A product's water resistance is not a permanent feature; it degrades over time and requires proper care to maintain its effectiveness.

Why Performance Fades

The DWR coating is the most vulnerable element. Dirt, body oils, and abrasion from regular use can clog and wear down this chemical finish, allowing the fabric to absorb water and "wet out."

When the outer fabric becomes saturated, it feels wet and heavy, and even if a PU coating prevents leaks, the material's breathability is eliminated.

How to Restore Water Resistance

Maintaining performance is a two-step process. First, clean your gear according to the manufacturer's instructions to remove contaminants that inhibit the DWR.

Second, if water no longer beads, you must re-apply the DWR finish. This is easily done with widely available spray-on or wash-in reproofing products, which restore the fabric's ability to shed water.

Making the Right Choice for Your Goal

- If your primary focus is daily use and light showers: Standard Cordura with a factory-applied DWR finish is perfectly adequate.

- If your primary focus is serious protection for outdoor activities: Seek out products that specify both a DWR finish and an additional PU coating for maximum water resistance.

- If your primary focus is maintaining existing gear: Regularly clean and reproof your items with a DWR treatment to ensure they perform as intended for years.

Understanding these factors empowers you to select the right product and properly maintain it for lasting performance.

Summary Table:

| Factor | Key Element | Impact on Water Resistance |

|---|---|---|

| Fabric Construction | Denier & Weave Density | Creates the initial physical barrier against moisture. |

| Coatings & Treatments | DWR & PU Coatings | Causes water to bead up and provides an impermeable layer. |

| Care & Maintenance | Cleaning & Reproofing | Restores and maintains the material's long-term performance. |

Need high-performance, water-resistant footwear or gear? As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear and boots for distributors, brand owners, and bulk clients. Our expertise in material science ensures optimal performance for your market. Let's discuss your specific requirements — contact our team today to explore production possibilities!

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- How does a multi-dimensional analysis grid assist in the quality classification of diverse footwear types? Master Precision Quality Control

- What role do shoe-mounted wireless sensors play in motion tracking? The Gold Standard for Professional Accuracy

- What materials are commonly used for cowboy boots? A Guide to Leather, Exotics & Soles

- Why does the article advise against waterproof shoes? Uncover the Hidden Drawbacks

- What is the purpose of integrating wearable ankle braces with specialized footwear? High-Fidelity Bio-Mechanical Data

- How are optical motion capture and force plates used to validate wearable insoles? Ensure Gold-Standard Accuracy.

- What are the key features of off-road and motocross motorcycle boots? Essential Protection for Demanding Rides

- Why is a deadener added to the silicone base for tissue surrogates? Achieve Bio-Fidelity in Impact Testing