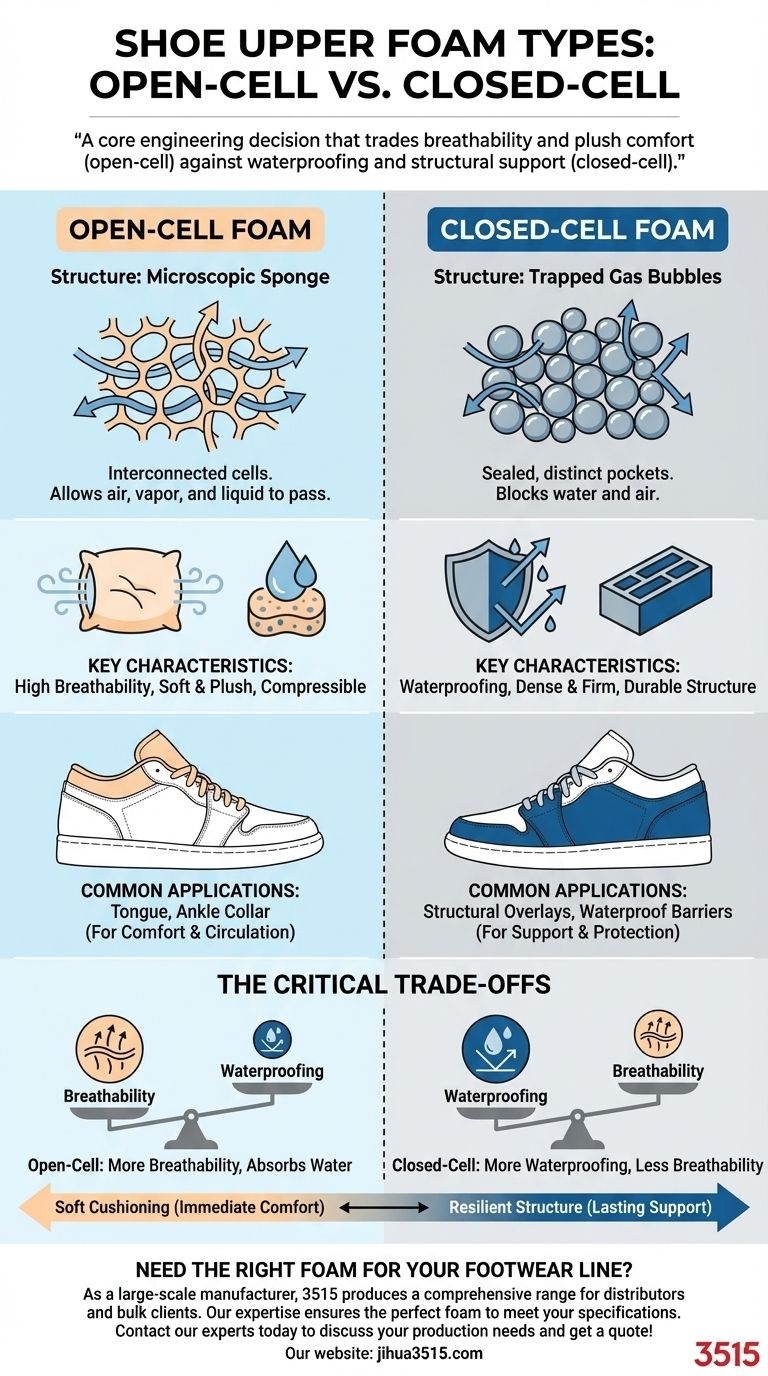

The two primary types of foam used in shoe uppers are open-cell foam and closed-cell foam. Their fundamental difference lies in their cellular structure, which dictates whether they are breathable and soft or waterproof and dense.

The choice between open-cell and closed-cell foam in a shoe's upper is a core engineering decision that trades breathability and plush comfort (open-cell) against waterproofing and structural support (closed-cell).

Understanding Open-Cell Foam

Open-cell foam is defined by its internal structure, where the individual cells are not completely sealed off from one another.

The Structure: A Microscopic Sponge

Think of open-cell foam as a very fine kitchen sponge. The cells are interconnected, creating a network of tiny pathways.

This structure allows air, vapor, and even liquid to pass directly through the material.

Key Characteristics

The primary characteristic of open-cell foam is breathability. It allows heat and moisture from your foot to escape, which is critical for comfort.

It is also typically softer and more compressible, providing a plush, cushioned feel. Polyurethane foam is a common example used in footwear.

Common Applications in Uppers

Because of its properties, open-cell foam is most often used in areas where comfort and air circulation are paramount, such as the tongue and the ankle collar of a shoe.

Understanding Closed-Cell Foam

Closed-cell foam has a structure where each individual cell is a completely sealed, distinct pocket of gas.

The Structure: Trapped Gas Bubbles

Imagine this foam as a collection of tiny, unpoppable balloons pressed tightly together. Gas and liquid cannot pass from one cell to the next.

This structure makes the material inherently water-resistant and airtight.

Key Characteristics

The defining feature of closed-cell foam is its impermeability. It blocks the passage of water and air, making it an excellent material for waterproofing.

It is also generally denser, firmer, and more durable than open-cell foam. Common examples include EVA (ethylene-vinyl acetate), PE (polyethylene), and SBR (styrene-butadiene rubber).

Common Applications in Uppers

While famous for its use in midsoles, closed-cell foam is used in uppers where structure, support, or weather protection is needed. It can form structural overlays or serve as a waterproof barrier.

The Critical Trade-offs

Choosing between these foams is never about which one is "better" overall, but which is better for a specific purpose.

Breathability vs. Waterproofing

This is the most significant trade-off. Open-cell foam excels at letting your foot breathe but will absorb water quickly. Closed-cell foam provides excellent water resistance but offers very little breathability.

Soft Cushioning vs. Resilient Structure

Open-cell foam provides immediate, soft comfort but can be less durable and may compress over time. Closed-cell foam offers firmer, more lasting support and is more resistant to compression.

How to Apply This to Your Choice

Understanding this distinction helps you evaluate a shoe's intended purpose and performance.

- If your primary focus is breathability and all-day comfort for dry conditions: Look for shoes that prominently feature open-cell foams in the collar and tongue for superior cushioning and air exchange.

- If your primary focus is weather resistance and rugged durability: Choose footwear that strategically incorporates closed-cell foams in the upper construction for waterproofing and support.

Knowing the role of each foam empowers you to select footwear engineered precisely for your needs.

Summary Table:

| Feature | Open-Cell Foam | Closed-Cell Foam |

|---|---|---|

| Structure | Interconnected cells (like a sponge) | Sealed, individual cells (like balloons) |

| Breathability | High (allows air/moisture to pass) | Low (air/moisture cannot pass) |

| Water Resistance | Low (absorbs water) | High (waterproof) |

| Feel & Comfort | Soft, plush, compressible | Dense, firm, supportive |

| Common Uses in Uppers | Tongue, ankle collar (for comfort) | Structural overlays, waterproof barriers |

Need the right foam for your footwear line? As a large-scale manufacturer, 3515 produces a comprehensive range of shoes and boots for distributors, brand owners, and bulk clients. Our expertise in material science ensures we select the perfect foam—whether open-cell for breathable comfort or closed-cell for waterproof durability—to meet your exact specifications and performance goals.

Contact our experts today to discuss your production needs and get a quote!

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

People Also Ask

- What role does the 16x2 LCD display module play in smart metal detection shoes? Key Benefits for Field Operations

- What is the function of PET fiber in sustainable footwear? Transform Recycled Plastic into High-Performance Shoes

- How do advanced manufacturing processes like SPS impact sports equipment quality? Gain a High-Performance Edge

- What are the key anatomical differences between male and female feet? Find the Perfect Fit for Your Foot Shape

- What role do laboratory-grade force platforms play in designing outsoles? Engineering Peak Stability and Power

- What are the key protective features of motorcycle-specific boots? Essential Safety for Every Rider

- Why are external flexible connectors and independent hubs utilized in diabetic foot monitoring systems? Maximize Comfort

- What is the purpose of using an industrial-standard whole-shoe flexing tester for banana fiber footwear? Ensure Durability