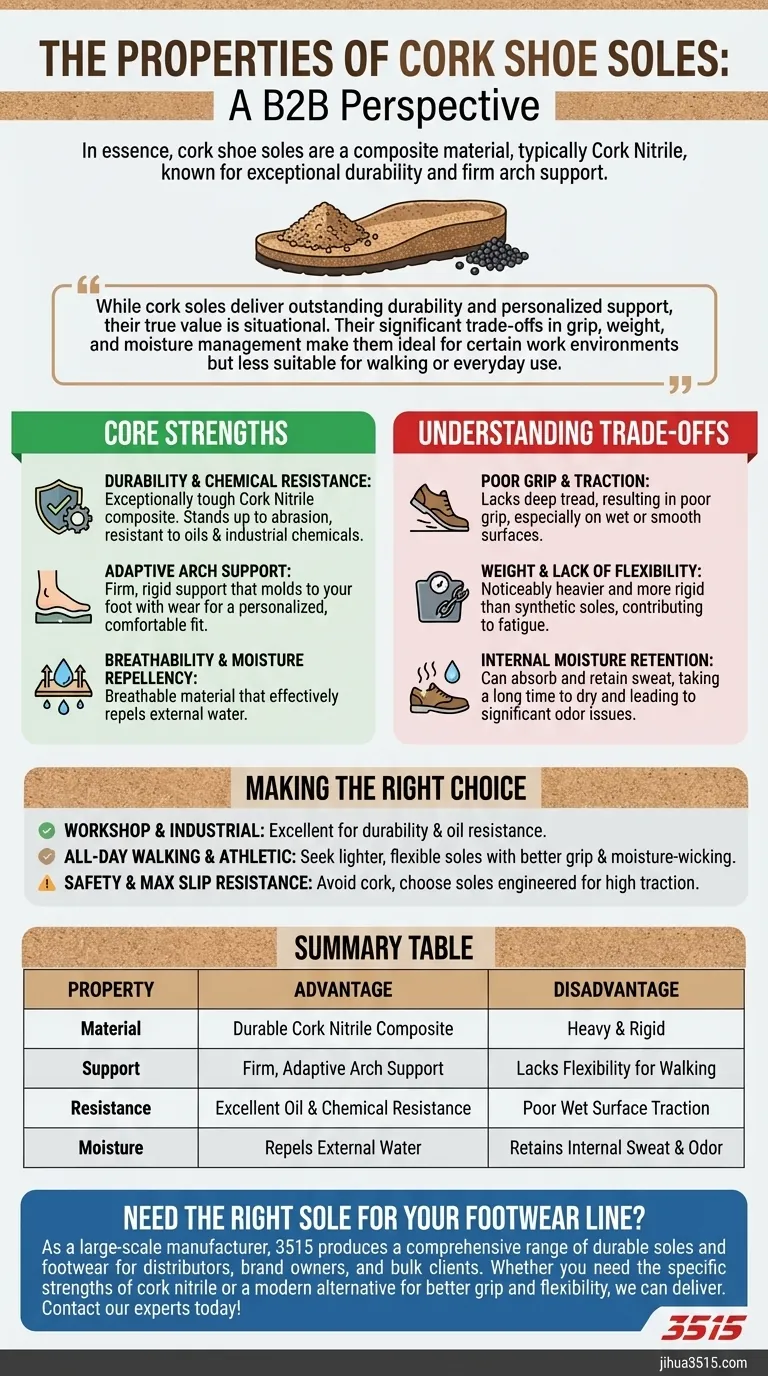

In essence, cork shoe soles are a composite material, typically Cork Nitrile, known for exceptional durability and firm arch support. They are highly resistant to oils and water, and their slightly elastic nature allows them to gradually conform to the shape of the wearer's foot, providing a custom fit over time.

While cork soles deliver outstanding durability and personalized support, their true value is situational. Their significant trade-offs in grip, weight, and moisture management make them ideal for certain work environments but less suitable for walking or everyday use.

The Core Strengths of Cork Soles

Cork's unique cellular structure, when combined with nitrile, creates a sole with very specific advantages. These properties make it a long-standing choice for heavy-duty footwear.

Durability and Chemical Resistance

The Cork Nitrile composite is exceptionally tough. It stands up well to abrasion and is highly resistant to degradation from oils and other common industrial chemicals.

This makes it a reliable choice for soles on work boots used in workshops, garages, and manufacturing facilities where such exposures are common.

Adaptive Arch Support

Unlike softer, more flexible materials, cork provides firm, rigid support from the start. Its key advantage is a slight elasticity that allows it to compress and mold to the unique contours of your foot with repeated wear.

This molding process creates a personalized footbed that offers excellent, customized arch support, which many find highly comfortable for long periods of standing.

Breathability and Moisture Repellency

The natural properties of cork make it both breathable and repellent to external moisture. It effectively keeps water from soaking into the sole from the outside.

Understanding the Trade-offs: Where Cork Falls Short

No material is perfect, and the very properties that make cork strong in some areas create significant disadvantages in others. These trade-offs are critical to understand.

Poor Grip and Traction

Cork soles inherently lack a deep, natural tread. This results in poor grip strength, especially on wet or smooth surfaces.

While durable, this makes them a liability in environments where slip resistance is a primary safety concern, unlike specialized safety soles designed for maximum traction.

Weight and Lack of Flexibility

Cork soles are noticeably heavier and more rigid than modern synthetic soles. This weight can contribute to fatigue over a long day.

Their rigidity is the opposite of what is needed in a good walking shoe, which requires a soft, flexible sole to allow the foot to push off easily with each step.

Internal Moisture Retention

While cork repels external water, it can absorb and retain sweat from the foot. The dense material takes a very long time to dry out completely.

This retained moisture can lead to significant odor issues, making cork a problematic choice for everyday shoes worn for extended periods.

Making the Right Choice for Your Footwear

Selecting the right sole material depends entirely on the shoe's intended purpose. The strengths of a cork sole are best applied to a narrow set of conditions.

- If your primary focus is durability in a workshop or industrial setting: A Cork Nitrile sole is an excellent choice due to its longevity and resistance to oils.

- If your primary focus is all-day walking comfort or athletic performance: You should seek lighter, more flexible soles with superior grip and modern moisture-wicking capabilities.

- If your primary focus is safety and maximum slip resistance: Avoid cork and choose a sole specifically engineered for high traction on wet or slick surfaces.

Ultimately, understanding these distinct properties allows you to select a sole that truly serves its intended purpose.

Summary Table:

| Property | Advantage | Disadvantage |

|---|---|---|

| Material | Durable Cork Nitrile Composite | Heavy & Rigid |

| Support | Firm, Adaptive Arch Support | Lacks Flexibility for Walking |

| Resistance | Excellent Oil & Chemical Resistance | Poor Wet Surface Traction |

| Moisture | Repels External Water | Retains Internal Sweat & Odor |

Need the right sole for your footwear line? As a large-scale manufacturer, 3515 produces a comprehensive range of durable soles and footwear for distributors, brand owners, and bulk clients. Whether you need the specific strengths of cork nitrile or a modern alternative for better grip and flexibility, we can deliver. Contact our experts today to discuss your production needs!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Safety Shoes with Rotating Buckle Safety Sneakers

People Also Ask

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene