Applying wax-based waterproofing is a straightforward process of warming the wax, working a thin layer into the boot's leather with a cloth or your fingers, and buffing off the excess after it has dried completely. The most critical steps happen before you even open the tin: ensuring your boots are clean and confirming they are made of a compatible material like full-grain leather.

The effectiveness of wax waterproofing lies not just in the application technique, but in proper preparation. Starting with clean, dry boots made of the right type of leather is essential for creating a durable, water-repellent seal.

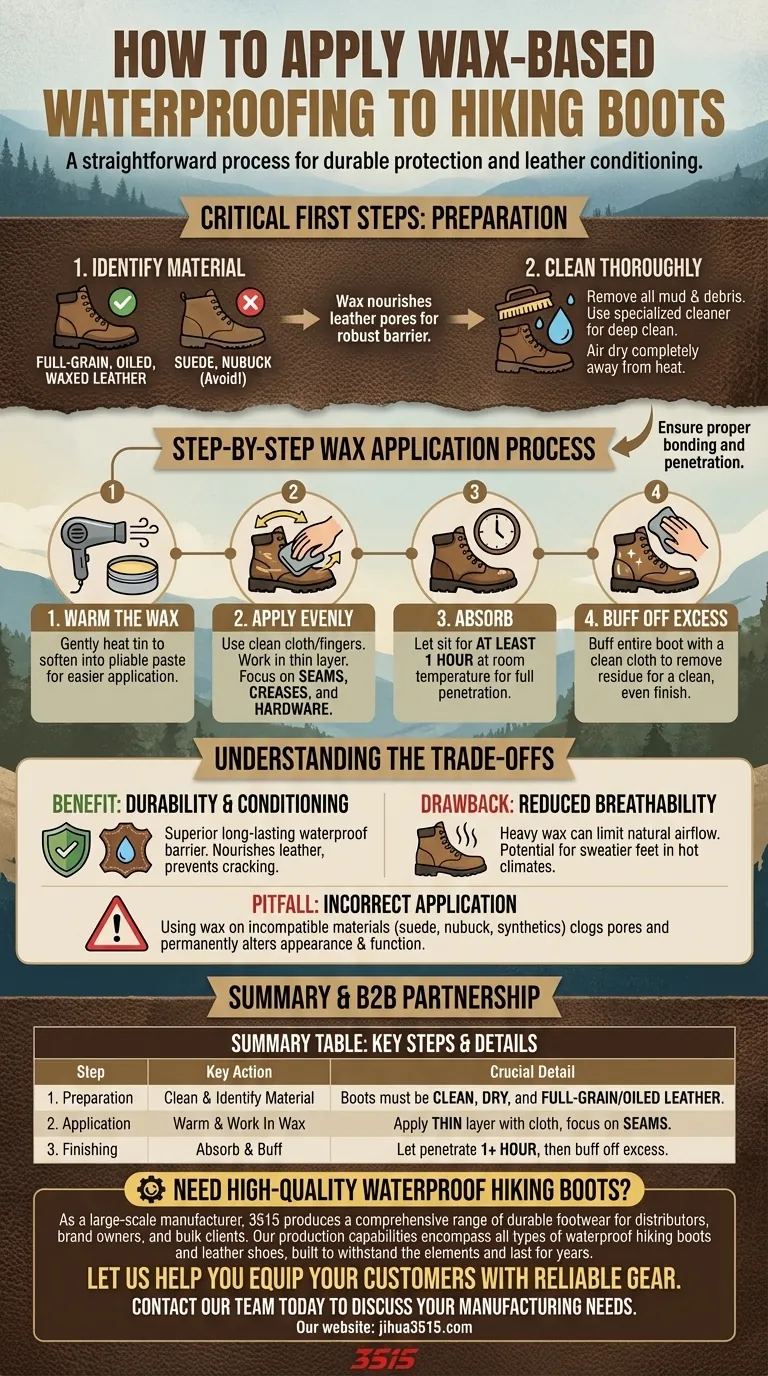

Before You Begin: The Critical First Steps

Applying wax to the wrong material or to a dirty boot can do more harm than good. Proper preparation ensures the wax can fully penetrate and protect the leather.

Identify Your Boot Material

The first step is to confirm wax is the right treatment for your gear. Different materials require different care.

Wax-based treatments are designed for full-grain, oiled, or already-waxed leather. The wax is meant to absorb into the leather's pores, nourishing it and creating a robust water barrier.

Avoid using wax on suede or nubuck leathers. The heavy wax will ruin the napped texture and can significantly compromise the material's natural breathability.

Thoroughly Clean Your Boots

Never apply a new waterproofing coat over dirty boots. Dirt and grime trapped under the wax can degrade the leather over time and prevent the treatment from bonding properly.

Use a brush and water to remove all mud and debris. For a deeper clean, use a specialized footwear cleaner, then allow your boots to air dry completely away from direct heat.

The Step-by-Step Wax Application Process

With clean and dry boots, you can now apply the wax for maximum protection.

Warm the Wax

Gently warm the tin of wax with a hairdryer. This softens it from a hard solid into a pliable paste, making it much easier to apply and helping it absorb into the leather.

Apply the Wax Evenly

Using a clean cloth or your fingers, apply a small amount of wax to the boot. Work it into the leather using small, circular motions.

Pay special attention to seams, creases, and the area around hardware like eyelets, as these are common failure points for water entry.

Allow for Complete Absorption

Let the boots sit at room temperature for at least an hour, or as directed by the product instructions. This allows the wax to fully penetrate the leather's pores.

Buff Off the Excess

Once the wax is absorbed and the surface feels dry, take a clean cloth and buff the entire boot. This removes any excess residue and creates a clean, even finish.

Understanding the Trade-offs of Wax

While highly effective, wax is a specific tool for a specific job. Understanding its limitations is key to proper boot care.

Benefit: Durability and Conditioning

Wax provides a very durable and long-lasting waterproof barrier. It also acts as a conditioner for full-grain leather, keeping it nourished and preventing it from drying out and cracking.

Drawback: Reduced Breathability

A heavy application of wax can reduce the leather's natural breathability. This is a trade-off for its superior water resistance. If you hike primarily in hot, dry climates, this could lead to sweatier feet.

Pitfall: Incorrect Material Application

The most common mistake is applying wax to incompatible materials. Using it on suede, nubuck, or boots with synthetic fabric panels can clog their pores, permanently altering their appearance and function.

Making the Right Choice for Your Gear

Use this guidance to select the best waterproofing method for your specific hiking boots.

- If your primary focus is maximum water resistance for full-grain leather boots: A traditional wax-based treatment offers the most robust and durable protection.

- If your primary focus is maintaining the look and breathability of nubuck or suede: Avoid wax entirely and use a specialized spray-on waterproofing treatment designed for those materials.

- If your primary focus is treating boots with mixed fabric-and-leather panels: A silicone-based spray is a more versatile choice that won't damage the fabric sections.

Properly waterproofing your boots not only keeps your feet dry but is the single best thing you can do to extend the life of your investment.

Summary Table:

| Step | Key Action | Crucial Detail |

|---|---|---|

| 1. Preparation | Clean & Identify Material | Boots must be clean, dry, and made of full-grain or oiled leather. |

| 2. Application | Warm & Work In Wax | Apply a thin, even layer with a cloth, focusing on seams and creases. |

| 3. Finishing | Absorb & Buff | Let wax penetrate for at least an hour, then buff off excess residue. |

| Key Consideration | Trade-off | Wax offers superior durability but reduces breathability. |

Need High-Quality Waterproof Hiking Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of waterproof hiking boots and leather shoes, built to withstand the elements and last for years.

Let us help you equip your customers with reliable gear. Contact our team today to discuss your manufacturing needs and explore our catalog.

Visual Guide

Related Products

- Premium Oil Wax Leather Safety Boots for Bulk Purchase

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- How do ASTM and OSHA differ in their functions? Understand Their Critical Roles in Workplace Safety

- What boots do they wear on oil rigs? Essential Safety Footwear for Harsh Conditions

- What tips can help ensure safety toe boots fit correctly? Achieve Optimal Protection & Comfort

- What materials are used for fasteners and laces in safety boots? | A Guide to Durability & Safety

- How does routine boot maintenance benefit workplace safety? Proactive PPE Protection for Your Workforce