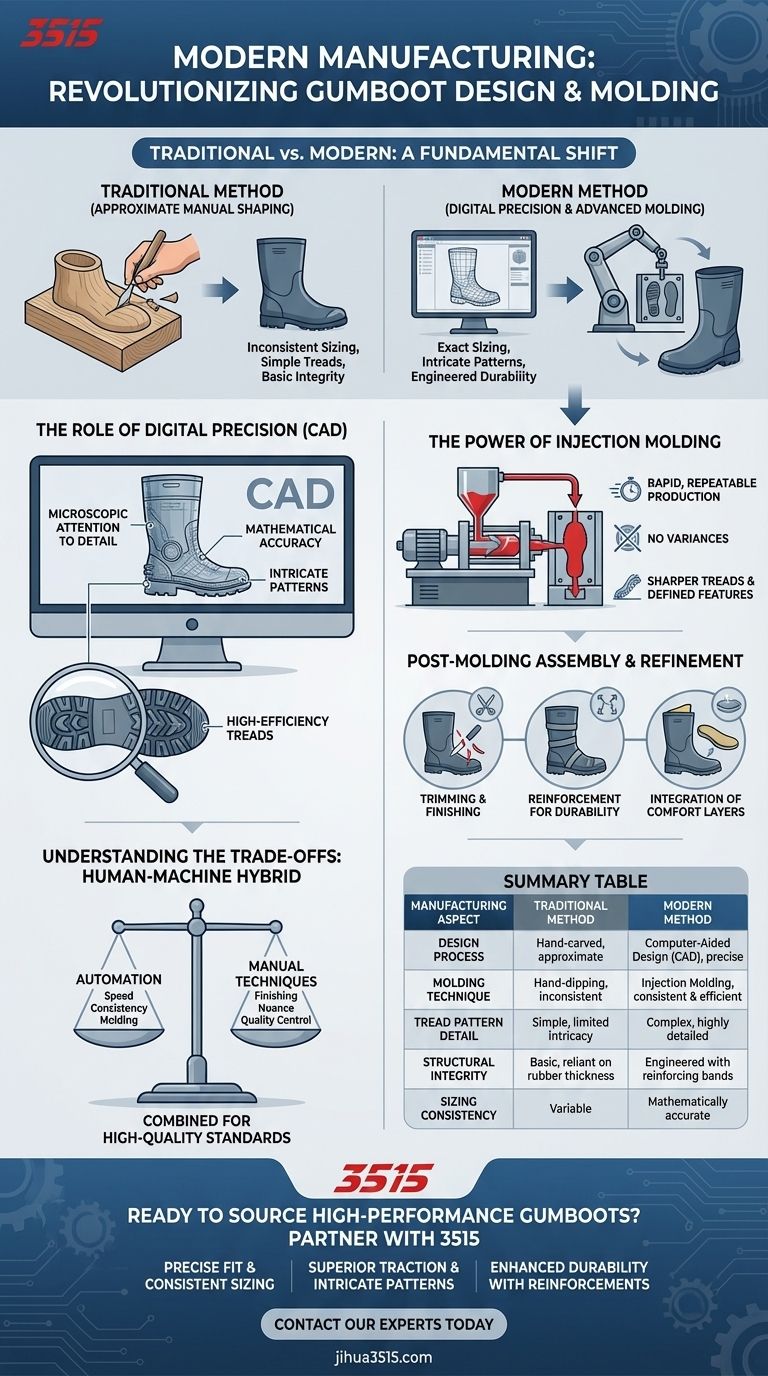

Modern manufacturing has fundamentally transformed gumboot production by replacing approximate manual shaping with digital precision and advanced molding techniques. By integrating Computer-Aided Design (CAD) with high-efficiency injection molding, manufacturers can now achieve exact sizing, intricate tread patterns, and consistent structural integrity that traditional methods could not sustain at scale.

The core shift in modern gumboot manufacturing is the move from simple shaping to precision engineering. By combining digital design with injection molding, manufacturers ensure that critical features like traction and reinforcement are built into the boot's DNA, rather than applied superficially.

The Role of Digital Precision

To understand the impact of modern manufacturing, one must look at how the design phase dictates the final product.

Precision via Computer-Aided Design (CAD)

The process begins with Computer-Aided Design (CAD). This technology allows engineers to create molds with microscopic attention to detail.

Unlike hand-carved molds of the past, CAD ensures that the desired style and size are replicated with absolute mathematical accuracy every time.

Intricacy in Patterning

Modern aesthetic and functional demands require complex designs. CAD enables the creation of intricate patterns on the boot’s surface and sole that would be nearly impossible to achieve manually.

The Power of Injection Molding

Once the precise mold is created, the manufacturing process relies on injection molding to actualize the design.

Efficiency and Consistency

Injection molding is the engine of modern gumboot production. It allows for rapid, repeatable production without the variances inherent in hand-dipped methods.

Capturing Fine Detail

This method excels at capturing the detail in complex patterns. The high pressure of injection molding forces material into every crevice of the CAD-designed mold, resulting in sharper treads and more defined features.

Post-Molding Assembly and Refinement

While molding provides the shape, the functionality of the boot is finalized during the assembly phase.

Trimming and Finishing

immediately after molding, excess material is trimmed away. This step is crucial for removing "flash" (leaked material) to ensure a clean, professional finish.

Reinforcement for Durability

Modern manufacturing allows for the integration of specific components to increase lifespan. Reinforcing bands are added to high-stress areas to provide necessary strength and prevent splitting.

Integration of Comfort Layers

A raw molded boot offers little comfort. The assembly process includes the insertion of fabric linings to prevent chafing and insoles to provide arch support and cushioning.

Understanding the Trade-offs

While automation drives efficiency, it is not a standalone solution for high-quality footwear.

The Necessity of Hybrid Techniques

Automation excels at molding, but it lacks the nuance required for finishing. The most effective manufacturing processes combine manual and automated techniques.

Quality Control Dependencies

Relying solely on machines can lead to overlooked defects. Meeting high-quality standards often requires human oversight during the assembly of linings and reinforcing bands to ensure they are bonded correctly.

Making the Right Choice for Your Needs

When evaluating gumboots, understanding how they were made helps you predict their performance.

- If your primary focus is Durability: Look for boots featuring reinforcing bands, which indicate a post-molding assembly process focused on structural strength.

- If your primary focus is Traction and Fit: Prioritize boots created with CAD and injection molding, as these methods guarantee precise tread patterns and consistent sizing.

- If your primary focus is Comfort: Inspect the quality of the fabric linings and insoles, ensuring the manual assembly phase has effectively integrated these support layers.

Modern manufacturing turns the gumboot from a simple rubber casting into a sophisticated, multi-component system designed for performance.

Summary Table:

| Manufacturing Aspect | Traditional Method | Modern Method |

|---|---|---|

| Design Process | Hand-carved, approximate | Computer-Aided Design (CAD), precise |

| Molding Technique | Hand-dipping, inconsistent | Injection Molding, consistent & efficient |

| Tread Pattern Detail | Simple, limited intricacy | Complex, highly detailed |

| Structural Integrity | Basic, reliant on rubber thickness | Engineered with reinforcing bands |

| Sizing Consistency | Variable | Mathematically accurate |

Ready to source high-performance gumboots built with modern precision?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our advanced production capabilities, combining CAD design with high-efficiency injection molding, ensure every pair of gumboots delivers on:

- Precise Fit & Consistent Sizing: Perfect for uniform bulk orders.

- Superior Traction & Intricate Tread Patterns: Engineered for safety and performance.

- Enhanced Durability: Built with integrated reinforcements for longer lifespan.

Let us help you equip your workforce or product line with reliable, high-quality footwear. Contact our experts today to discuss your specific needs and get a quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium KPU Injection Athletic Style Safety Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What are the benefits of wearing gumboots for protection? Essential Safety for Hazardous Environments

- How does the tread design of PVC boots enhance functionality? Boost Safety and Comfort for Your Workforce

- How are the materials for PVC rain boots prepared before molding? The Foundation of Quality Footwear

- What are the best practices for storing rubber boots? Protect Your Investment for Years

- What should be considered when selecting wellington boots for dog walking? Find Your Perfect Fit for All-Weather Walks

- What were the initial uses of Wellington boots? From Battlefield to High Society

- Why is grip and traction important in women's wellies? Essential for Safety and Stability

- How are logos applied to PVC rain boots? Achieve Durable, High-Quality Branding