Choosing the right safety shoe is a systematic process of matching certified protective features to the specific, identified hazards of your work environment. The best choice is not a single brand or style, but the one that offers the correct protection, meets compliance standards, and provides a proper, comfortable fit for the duration of your workday.

The most common mistake is prioritizing a single feature or brand over a systematic assessment of your work environment. The correct approach is to first identify every potential hazard you face, and only then select footwear with the specific, certified protections required to mitigate those risks.

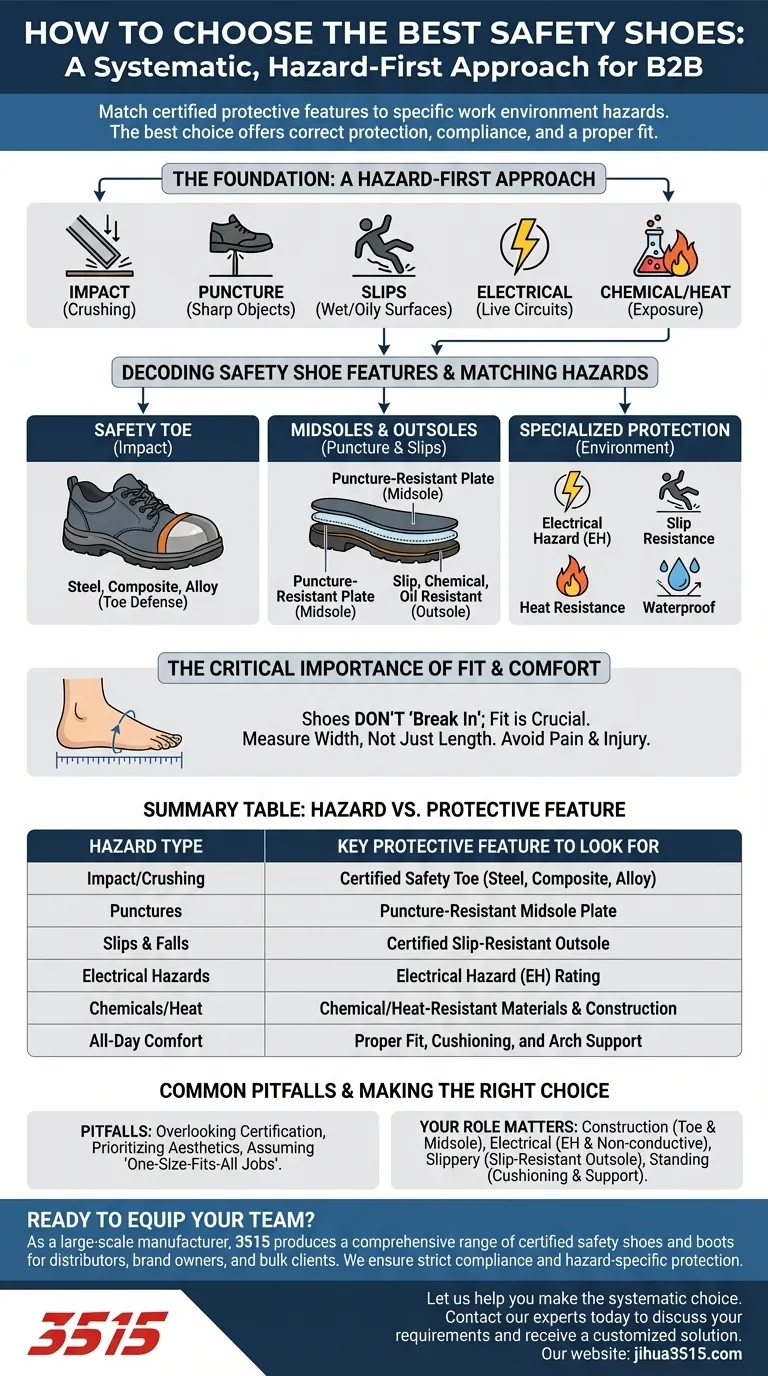

The Foundation: A Hazard-First Approach

The selection process must begin long before you look at a shoe. It starts with a clear understanding of the environment where the shoes will be worn.

Why Your Environment Dictates Your Choice

A safety shoe is a piece of specialized equipment. Just as you wouldn't use a hammer to turn a screw, you shouldn't use a general-purpose safety shoe in an environment with unique electrical, chemical, or puncture risks.

The shoe's features are designed to neutralize specific threats. Choosing the right shoe means you have correctly identified those threats in advance.

Conducting a Personal Hazard Assessment

Before evaluating any footwear, ask these critical questions about your workplace:

- Impact: What could fall on or crush my feet? (e.g., heavy materials, tools)

- Puncture: What could I step on? (e.g., nails, screws, sharp scrap metal)

- Slips: What are the floor surfaces like? (e.g., wet, oily, smooth, uneven)

- Electrical: Am I at risk of contact with live electrical circuits?

- Chemical/Heat: Will my feet be exposed to chemicals, acids, or extreme temperatures?

Decoding Safety Shoe Features

Once you understand the hazards, you can match them to the corresponding protective features. Each component of the shoe serves a distinct purpose.

The Safety Toe: Your First Line of Defense

This is the most fundamental feature, protecting your toes from impact and compression. It is typically made from steel, aluminum, or a non-metallic composite material.

Underfoot Protection: Midsoles and Outsoles

The midsole can include a puncture-resistant plate to protect you from stepping on sharp objects. The outsole is your contact with the ground, providing critical slip, chemical, and oil resistance.

Specialized Environmental Protections

Beyond the basics, many shoes offer specialized ratings:

- Electrical Hazard (EH): For electricians or maintenance workers, this rating signifies protection against open circuits.

- Slip Resistance: Crucial for wet or oily environments to prevent falls.

- Heat Resistance: Essential for workers in high-temperature settings like welding or asphalt work.

- Waterproof: A necessity for those who work outdoors or in constantly wet conditions.

The Critical Importance of Fit and Comfort

A safety shoe's protective features are compromised if the fit is incorrect. Discomfort is not just an inconvenience; it is a safety and health risk.

Why Safety Shoes Don't "Break In"

Unlike casual footwear, safety shoes are built with rigid, protective components. They will not stretch or conform to your foot over time. The fit must be correct from the first moment you wear them.

Measuring for a Proper Fit

An improper fit can cause stress on the shoe's structure and lead to pain or musculoskeletal issues. Always measure your feet and consult manufacturer sizing charts, paying close attention to width, not just length.

Common Pitfalls to Avoid

Making an informed choice means recognizing and avoiding common mistakes that can compromise your safety.

Overlooking Compliance and Certification

Always purchase from reputable sources and look for labels indicating compliance with safety standards like ISO or ASTM. A non-certified shoe offers no guaranteed protection. Check the manufacturer's technical data sheets to verify its features.

Prioritizing Aesthetics Over Function

While modern safety shoes offer more style options, aesthetics should never be the primary decision-making factor. The shoe's protective capabilities must always come first.

Assuming One Pair Fits All Jobs

If your work duties vary significantly, you may need more than one type of safety shoe. A shoe designed for a warehouse floor may not be suitable for outdoor construction work.

Making the Right Choice for Your Role

To select the ideal safety shoe, align your choice directly with your most critical daily requirements.

- If your primary focus is construction or industrial sites: Prioritize a certified safety toe and puncture-resistant midsoles to protect against falling objects and sharp debris.

- If your primary focus is working with electricity: Ensure your shoes have a clear Electrical Hazard (EH) rating and are built with non-conductive materials.

- If your primary focus is on wet or slippery surfaces: Select footwear with a high-traction, certified slip-resistant outsole designed for your specific floor type.

- If your primary focus is all-day standing comfort: Pay extra attention to cushioning, proper arch support, and ensuring the shoe's width is correct for your foot.

By systematically matching the shoe's certified features to your specific hazards, you transform your footwear from a requirement into a critical tool for professional safety and well-being.

Summary Table:

| Hazard Type | Key Protective Feature to Look For |

|---|---|

| Impact/Crushing | Certified Safety Toe (Steel, Composite, Alloy) |

| Punctures | Puncture-Resistant Midsole Plate |

| Slips & Falls | Certified Slip-Resistant Outsole |

| Electrical Hazards | Electrical Hazard (EH) Rating |

| Chemicals/Heat | Chemical/Heat-Resistant Materials & Construction |

| All-Day Comfort | Proper Fit, Cushioning, and Arch Support |

Ready to equip your team with the right safety footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety shoes and boots for distributors, brand owners, and bulk clients. We ensure every pair meets strict compliance standards and is built for the specific hazards of your industry.

Let us help you make the systematic choice for safety and comfort. Contact our experts today to discuss your requirements and receive a customized solution.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Sport Style Safety Boots for Bulk Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

People Also Ask

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- Is safety-toe as good as steel toe? Choose the Right Protection for Your Job

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health