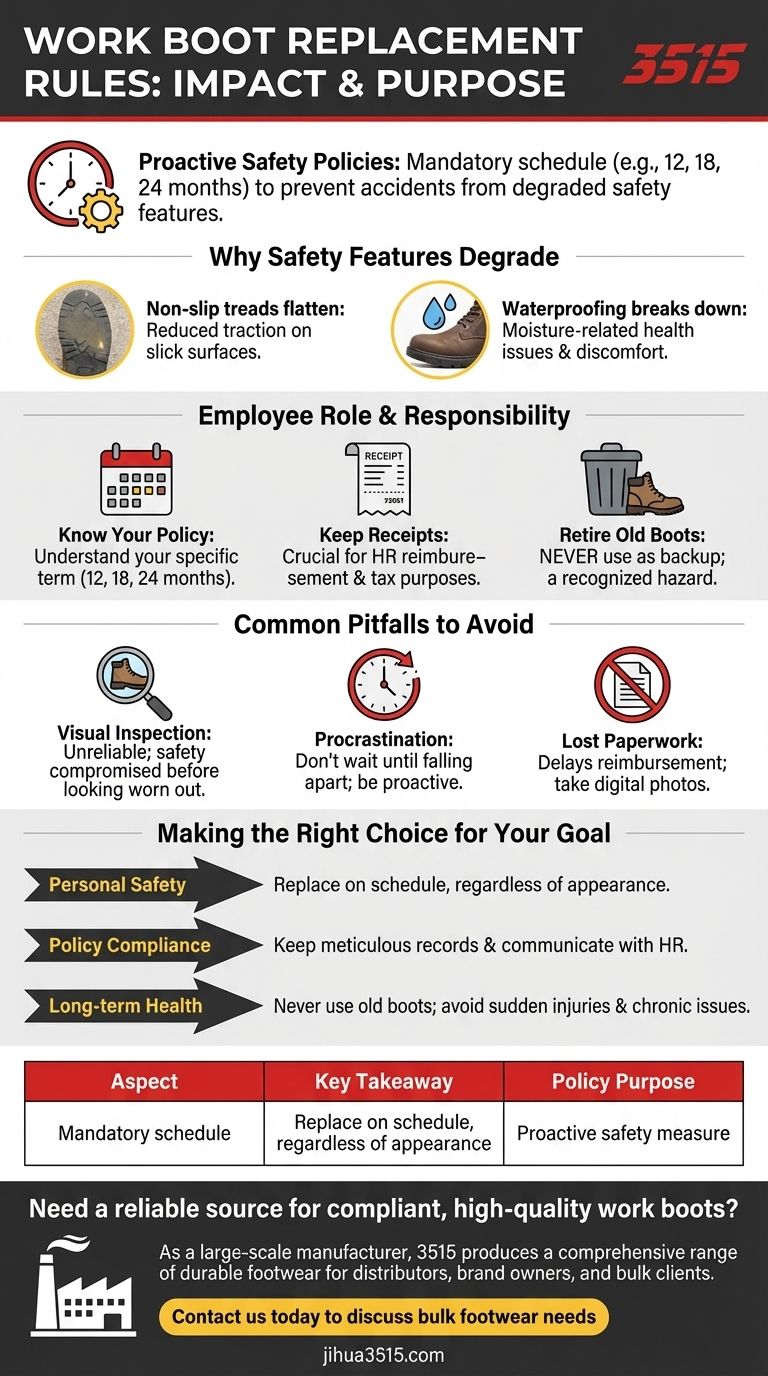

To put it simply, employer replacement rules are safety policies that dictate a mandatory schedule—often every 12, 18, or 24 months—for replacing employee work boots. This ensures that critical safety features, which degrade over time, remain effective and protect you from workplace hazards.

The core purpose of a boot replacement rule is not just about providing new gear; it's a proactive safety measure designed to prevent accidents by ensuring protective features like non-slip treads and waterproofing are never compromised by wear and tear.

The Core Purpose: Proactive Safety Management

Work boot replacement policies are a fundamental component of an employer's commitment to a safe working environment. They address the inevitable degradation of safety equipment through regular use.

Why Safety Features Degrade

Even the most durable boots have a limited lifespan. Key protective elements wear down with daily stress, moisture, and exposure to various materials on a job site.

This degradation includes the flattening of non-slip treads, reducing traction on slick surfaces, and the breakdown of waterproofing materials, which can lead to moisture-related health issues and discomfort.

The Employer's Responsibility

By setting a fixed replacement cycle, the employer removes guesswork. It creates a clear, enforceable standard that ensures every worker is protected by footwear that performs as designed.

This systematic approach helps companies maintain compliance with safety regulations and reduces the risk of preventable, and potentially costly, workplace injuries.

The Employee's Role in the Process

While the employer sets the policy, the employee has a critical role in its successful execution. Your active participation is essential for ensuring your own safety.

Understand Your Specific Policy

Your first step is to know the exact terms. Find out if your company's replacement cycle is 12, 18, 24 months, or another term. This information is typically found in the employee handbook or by asking HR.

The Importance of Documentation

Always keep your receipts when you purchase new, approved work boots. This documentation is crucial for two reasons.

First, your HR department will require it for reimbursement. Second, in some cases, work-related expenses that are not reimbursed can be tax-deductible, and proof of purchase is mandatory.

Retire Old Boots from Active Duty

Once you receive your new boots, the old pair must be permanently retired from the worksite. Using them as a "backup" completely undermines the safety policy.

Worn-out boots are a recognized hazard. Continuing to use them, even occasionally, exposes you to the very risks the replacement policy is designed to prevent.

Common Pitfalls to Avoid

Misunderstanding the purpose of these rules can lead to unsafe practices. Avoiding these common mistakes is crucial for maintaining a safe work environment for yourself and your colleagues.

Believing "They Still Look Fine"

A visual inspection is not a reliable safety test. The structural integrity of a boot, the composition of its sole, and the effectiveness of its waterproofing can be compromised long before the boot looks "worn out."

Forgetting to Follow Through

Don't wait until your boots are falling apart. Be proactive and begin the replacement process as you approach the end of your policy's cycle. A lapse in protection is a lapse in safety.

Losing the Paperwork

A lost receipt can delay or prevent your reimbursement. Create a system, such as taking a digital photo of the receipt immediately after purchase, to ensure you always have the necessary documentation for HR.

Making the Right Choice for Your Goal

Adhering to your employer's replacement rule is a shared responsibility that directly impacts your personal safety on the job.

- If your primary focus is personal safety: Always replace your boots according to the schedule, regardless of their outward appearance, to ensure you are fully protected.

- If your primary focus is policy compliance: Keep meticulous records, including all receipts, and communicate with HR to ensure a smooth and timely reimbursement process.

- If your primary focus is long-term health: Never use old work boots on the job, as their diminished support and failing protective features can contribute to both sudden injuries and chronic issues.

Ultimately, viewing your work boots as critical, disposable safety equipment—not just footwear—is the key to staying safe.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Policy Purpose | Proactive safety measure to prevent accidents from degraded boots. |

| Employee Role | Understand the schedule, keep receipts, and retire old boots. |

| Common Pitfall | Boots can be unsafe long before they look worn out. |

Need a reliable source for compliant, high-quality work boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and work shoes designed to meet stringent safety standards and withstand demanding work environments.

Contact us today to discuss your bulk footwear needs and ensure your workforce is equipped with reliable, compliant safety gear.

Visual Guide

Related Products

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

People Also Ask

- How are boots designed to meet the ASTM standard for electrical hazard protection?

- What makes roper boots versatile? The Ultimate Hybrid for Work, Riding, and Style

- What features make insulated and waterproof boots suitable for extreme weather? A Guide to Maximum Protection

- Why are puncture-resistant Wellington boots important? The Ultimate Defense Against Unseen Hazards

- What are the 11 NFPA 1977 standards for wildland fire boots? Ensure Total Foot Protection on the Fire Line

- How are PVC work boots manufactured? An Inside Look at Injection Molding

- What safety boots are recommended for the construction industry? Ensure Maximum Protection on the Job Site

- What features should junk removal workers look for in work boots? A Guide to Safety & Comfort