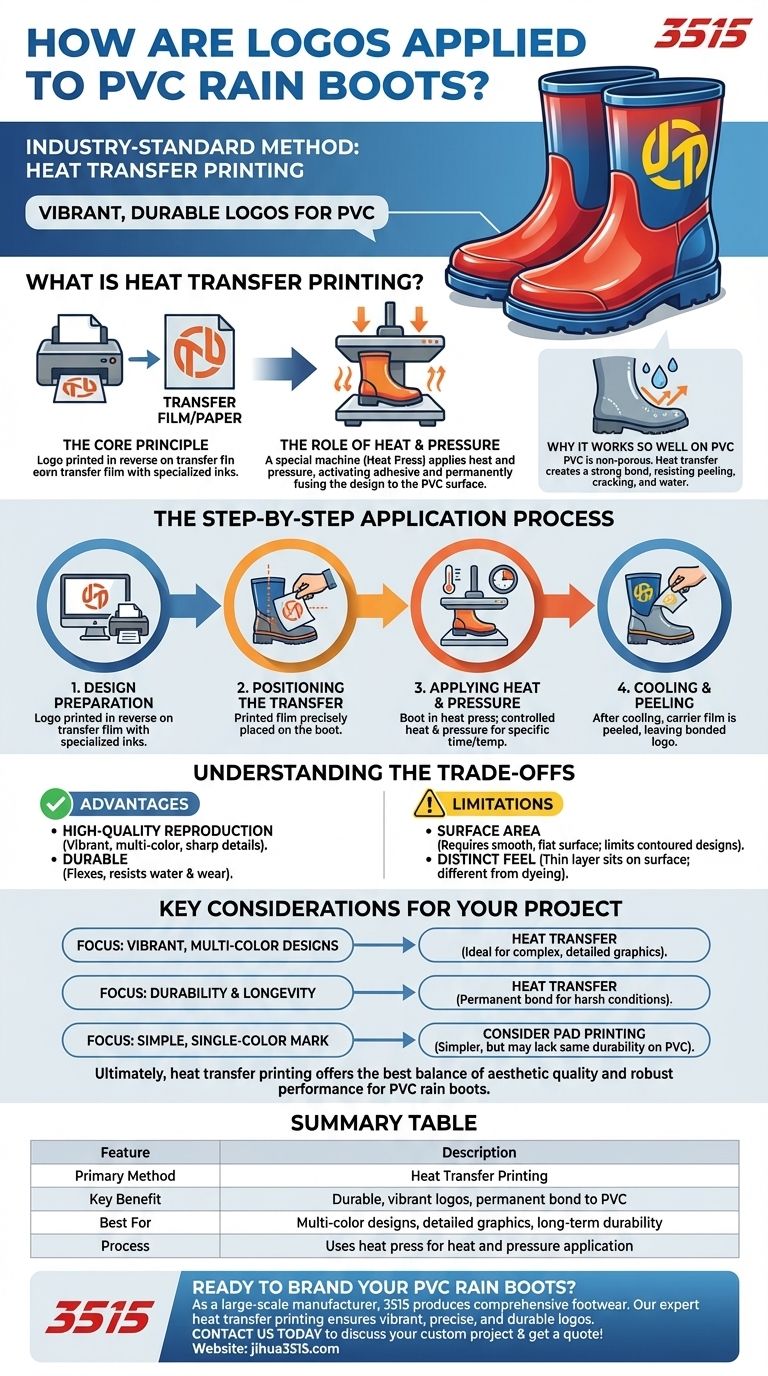

For PVC rain boots, the industry-standard method for applying a logo is a process known as heat transfer printing. This technology uses a combination of heat and pressure to permanently bond a pre-printed design directly onto the boot's upper, ensuring a durable and high-quality finish.

Heat transfer technology is the preferred method for branding PVC rain boots because it creates a vibrant, lasting logo that adheres strongly to the non-porous surface of the material, overcoming challenges where other printing methods might fail.

What is Heat Transfer Printing?

Heat transfer is a modern printing process that allows for the clean application of detailed, multi-color images onto various materials, including synthetics like PVC. It stands in contrast to methods that apply wet ink directly to a surface.

The Core Principle

The process involves printing the desired logo or design onto a special carrier material, often called transfer film or paper. This pre-printed design is essentially held in waiting.

The Role of Heat and Pressure

A specialized machine called a heat press is used to complete the application. It applies controlled heat and even pressure, which activates the adhesive on the back of the printed design, causing it to release from the carrier film and permanently fuse with the surface of the PVC boot.

Why It Works So Well on PVC

PVC is a smooth, non-porous plastic, which makes it difficult for traditional inks to absorb and adhere properly. The heat transfer method creates a strong, durable bond on top of the surface, resulting in a logo that won't easily peel, crack, or wash off with exposure to rain and abrasion.

The Step-by-Step Application Process

Understanding the workflow clarifies why this method is so reliable for manufacturing. Each step is designed for precision and permanence.

Step 1: Design Preparation

The customer's logo is digitally finalized and printed in reverse onto the heat transfer film using specialized inks.

Step 2: Positioning the Transfer

The printed film is carefully cut out and placed precisely on the desired location on the PVC boot upper.

Step 3: Applying Heat and Pressure

The boot is placed in a heat press. A heated element, often shaped to accommodate the boot's curve, presses the transfer film against the PVC for a specific duration and at a specific temperature.

Step 4: Cooling and Peeling

After the heat press cycle is complete, the boot is removed. Once it has cooled slightly, the carrier film is peeled away, leaving only the ink and adhesive of the logo perfectly bonded to the boot.

Understanding the Trade-offs

While heat transfer is the standard for PVC boots, it's important to understand its specific characteristics to align with your project goals.

The Advantages

The primary benefit is high-quality reproduction. Heat transfer can produce vibrant, full-color logos with sharp details and crisp edges. The resulting application is also highly durable, flexing with the boot and resisting water and wear.

The Limitations

The application requires a relatively smooth, flat surface area for the heat press to work effectively, which can limit logo placement on highly contoured boot designs. Additionally, the logo sits on the surface of the boot as a very thin layer, giving it a distinct feel compared to a method like dyeing, which isn't feasible on PVC.

Key Considerations for Your Project

Choosing the right customization depends on your specific branding goals and the complexity of your design.

- If your primary focus is vibrant, multi-color designs: Heat transfer is the ideal method for achieving complex and detailed graphics with exceptional clarity.

- If your primary focus is durability and brand longevity: This process creates a permanent bond designed to withstand the harsh conditions rain boots endure.

- If your primary focus is a simple, single-color mark: While heat transfer is excellent, simpler methods like pad printing could be explored, but they may not offer the same level of durability on PVC.

Ultimately, heat transfer printing provides the most reliable balance of aesthetic quality and robust performance required for branding PVC rain boots.

Summary Table:

| Feature | Description |

|---|---|

| Primary Method | Heat Transfer Printing |

| Key Benefit | Durable, vibrant logos that bond permanently to PVC |

| Best For | Multi-color designs, detailed graphics, and long-term durability |

| Process | Uses a heat press to apply heat and pressure for a permanent bond |

Ready to brand your PVC rain boots with a logo that lasts?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including expert application of durable logos via heat transfer printing. We ensure your branding is vibrant, precise, and built to withstand the elements.

Contact us today to discuss your custom rain boot project and get a quote!

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- What are Wellington boots and why are they popular? Unmatched Protection for Wet & Muddy Conditions

- How should half-boots be cleaned to maintain their condition? A Gentle Guide to Preserve Your Footwear

- Is it advisable to buy second-hand wellies for children? Protect Your Child's Foot Health & Development

- How did Wellington boots evolve during World War I? From Aristocratic Fashion to Military Necessity

- Can Wellington boots be customized? Get a Perfect Fit for Your Specific Needs

- Are Wellington boots typically oversized? The Truth Behind the Roomy Fit

- Do wellies stretch over time? The Truth About Rubber Boot Fit & Comfort

- In what hunting scenarios are rubber boots the best choice? Maximize Stealth & Dryness for Your Hunt